A vacuum balance method of vacuum pressure dipping technology and its device

A technology of vacuum pressure impregnation and balance method, which is applied to the device for coating liquid on the surface, insulating conductor/cable, coil manufacturing, etc., can solve the problems of poor impregnation effect and weak insulation strength, and achieves low cost and insulation. Uniform strength and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

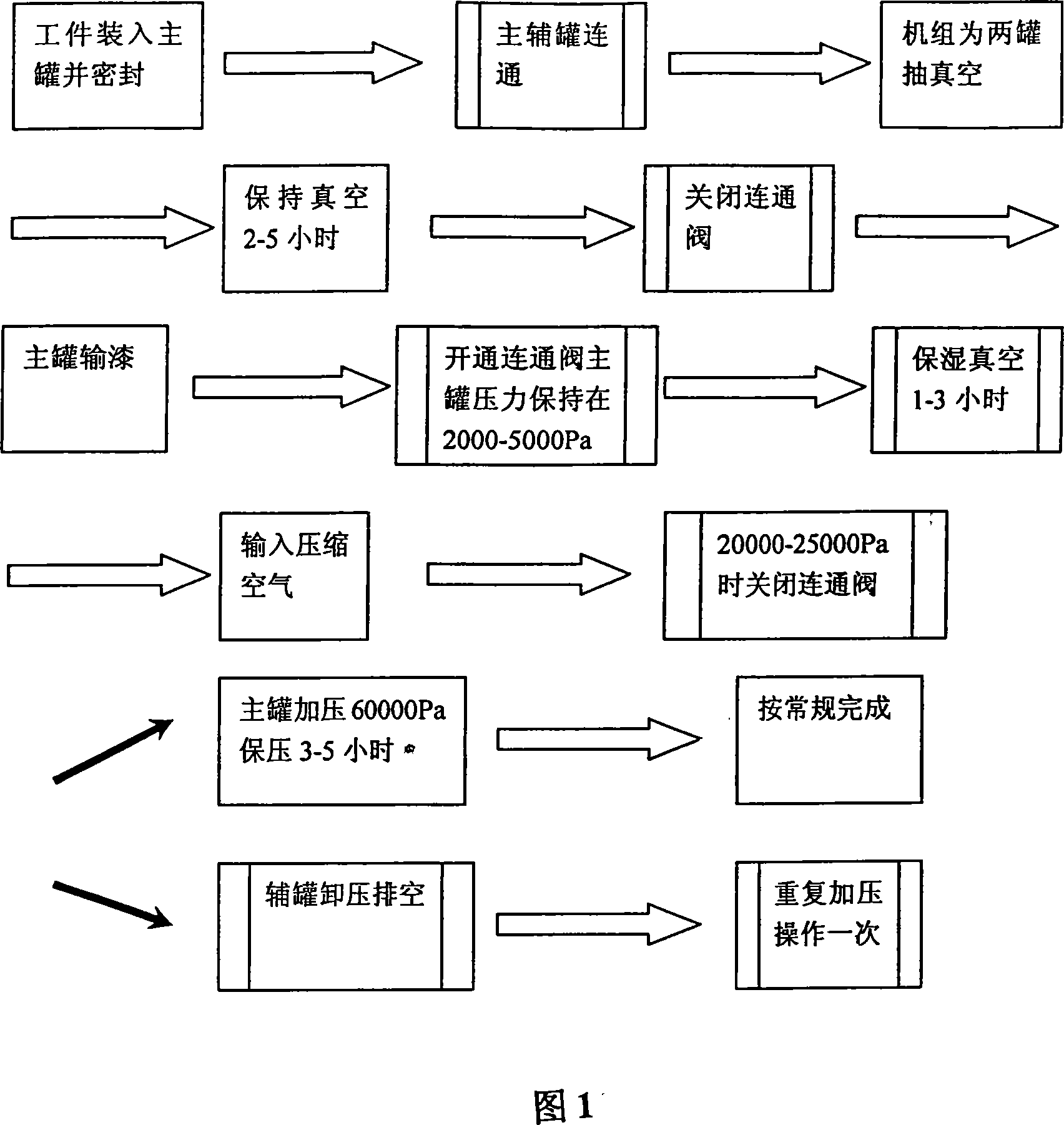

Method used

Image

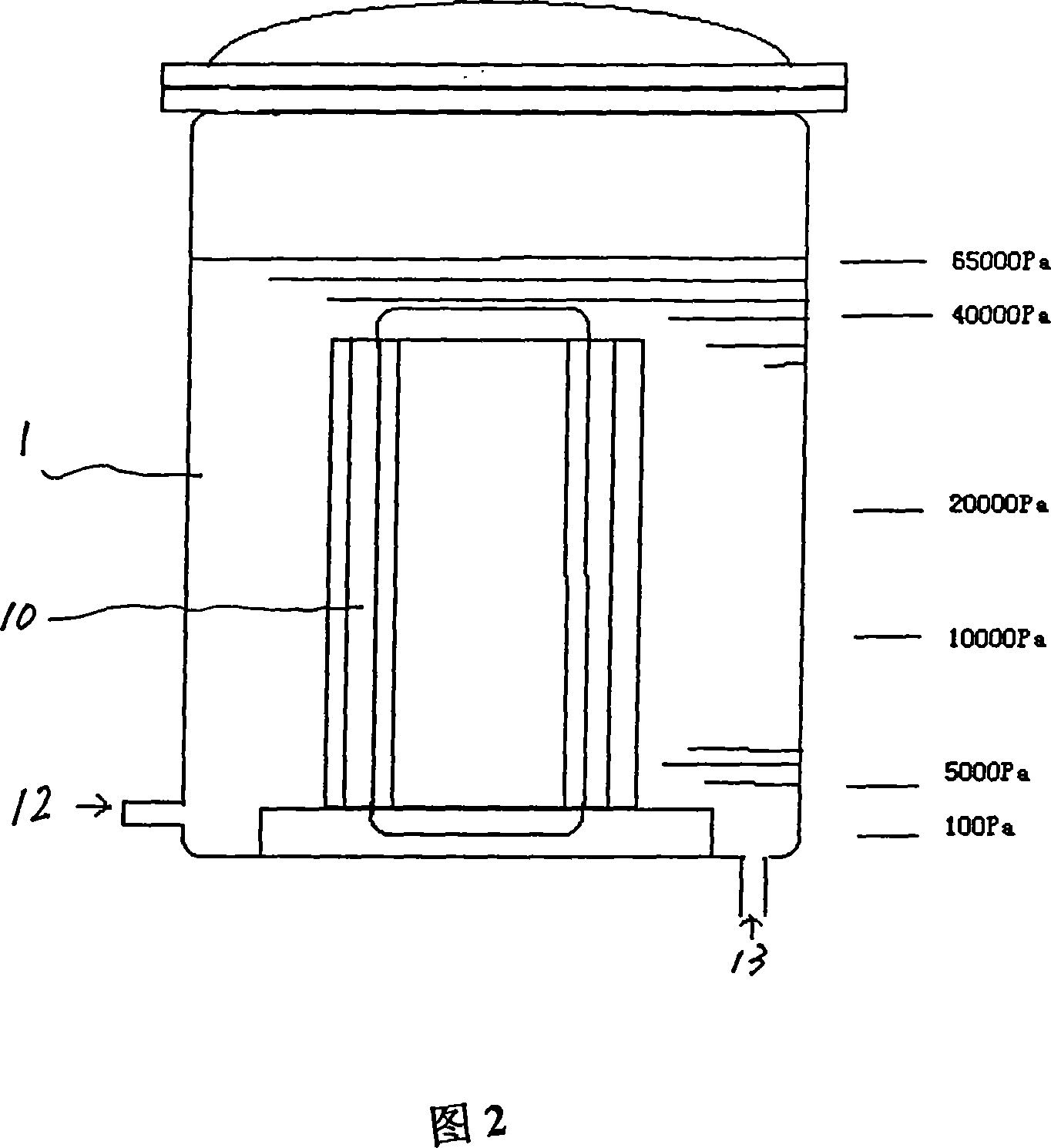

Examples

Embodiment 1

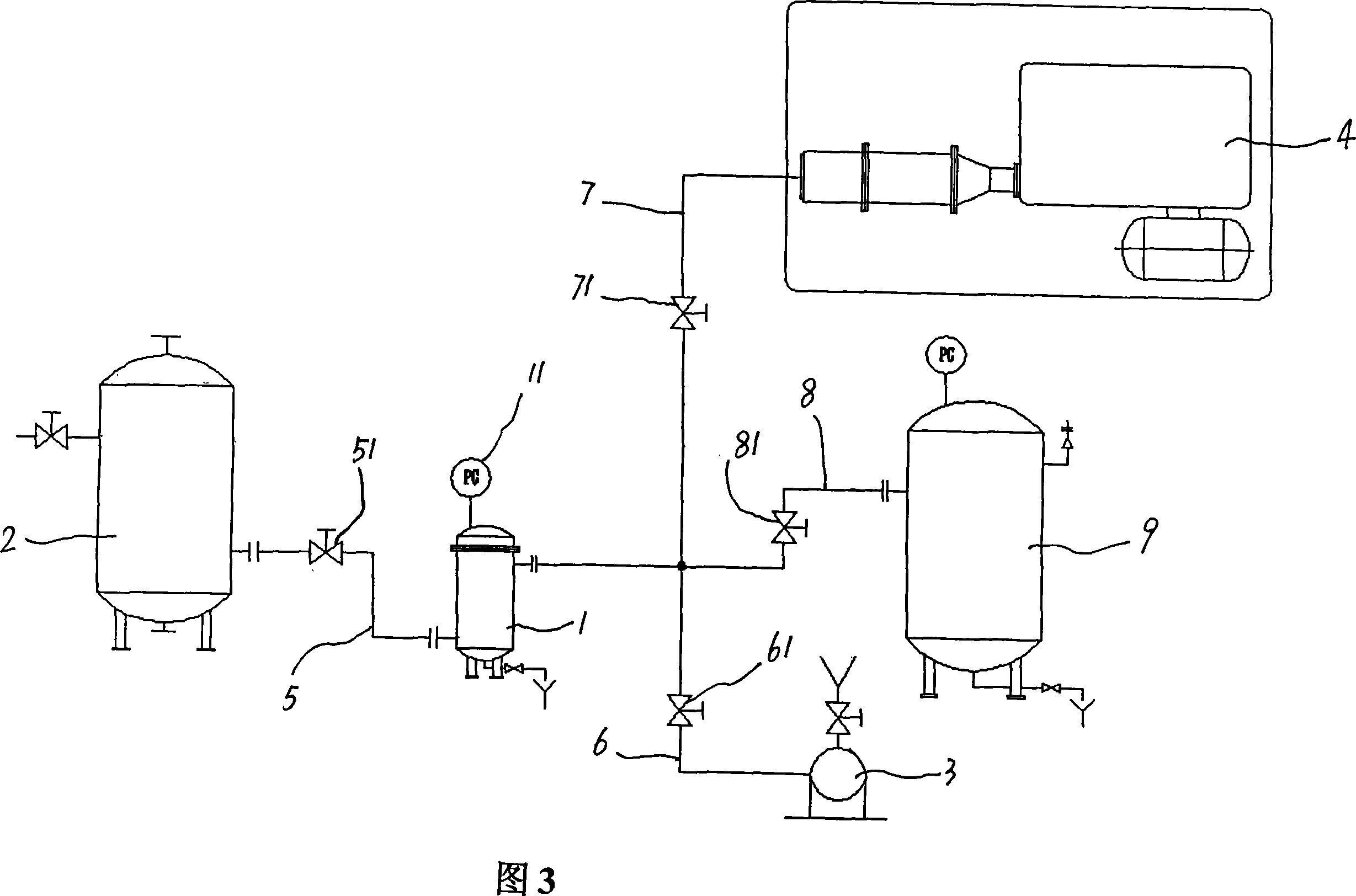

[0041] In Fig. 3, the vacuum pressure impregnation device includes: a paint dipping tank 1, a paint storage tank 2, a vacuum unit 3 and an air compressor unit 4, the bottom of the paint dipping tank 1 communicates with the bottom of the paint storage tank 2 through a paint delivery pipe 5, and The paint pipe 5 is provided with a two-way paint delivery valve 51, the paint delivery pipe 5 can transport the paint in the paint storage tank 2 to the paint soaking tank 1, and can also transport the paint in the paint soaking tank 1 back to the paint storage tank 2, two-way The paint conveying valve 51 is used to control the opening and closing of the paint conveying pipe 5. The upper part of the paint dipping tank 1 communicates with the vacuum unit 3 and the air compressor unit 4 through the pipelines 6 and 7 respectively, and the valves 61 and 71 are set on the pipelines 6 and 7 respectively. The upper part of the varnish tank 1 communicates with an air tank 9 through a communicati...

Embodiment 2

[0053] In the present embodiment, as shown in Figure 4, the balance mechanism is connected with the varnish tank 1' after four gas storage tanks 91, 92, 93, 94 are connected in series.

[0054] In this embodiment, the volume of the gas storage tank is 1-1.5 times that of the varnish tank 1', so as to facilitate the control of the pressure in the varnish tank 1' and keep it at the appropriate vacuum required by the dipping process. within range.

[0055] In this device, the paint dipping tank 1 ' and the paint storage tank 2 ' can also be provided with metering tanks (not shown in the figure); the bottom of the paint dipping tank 1 ' can be connected with a finished product storage tank (not shown in the figure).

[0056] In this embodiment, the pressure bearing capacity of the gas storage tank is 30Pa-300000Pa, which meets the relevant standards for pressure vessels. The purpose is to utilize the initial vacuum pressure (30-130Pa) of the air storage tank 9 to balance the risi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure endurance | aaaaa | aaaaa |

| Pressure endurance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com