A winding packing and non woof belt method at rotating electromotor end

A technology of rotating electrical machines and latitude-free tapes, which is applied in the manufacture of motor generators, windings, electrical components, etc., and can solve problems such as the loss of glue content, inoperability, and slowness of the latitude-free tapes at the bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

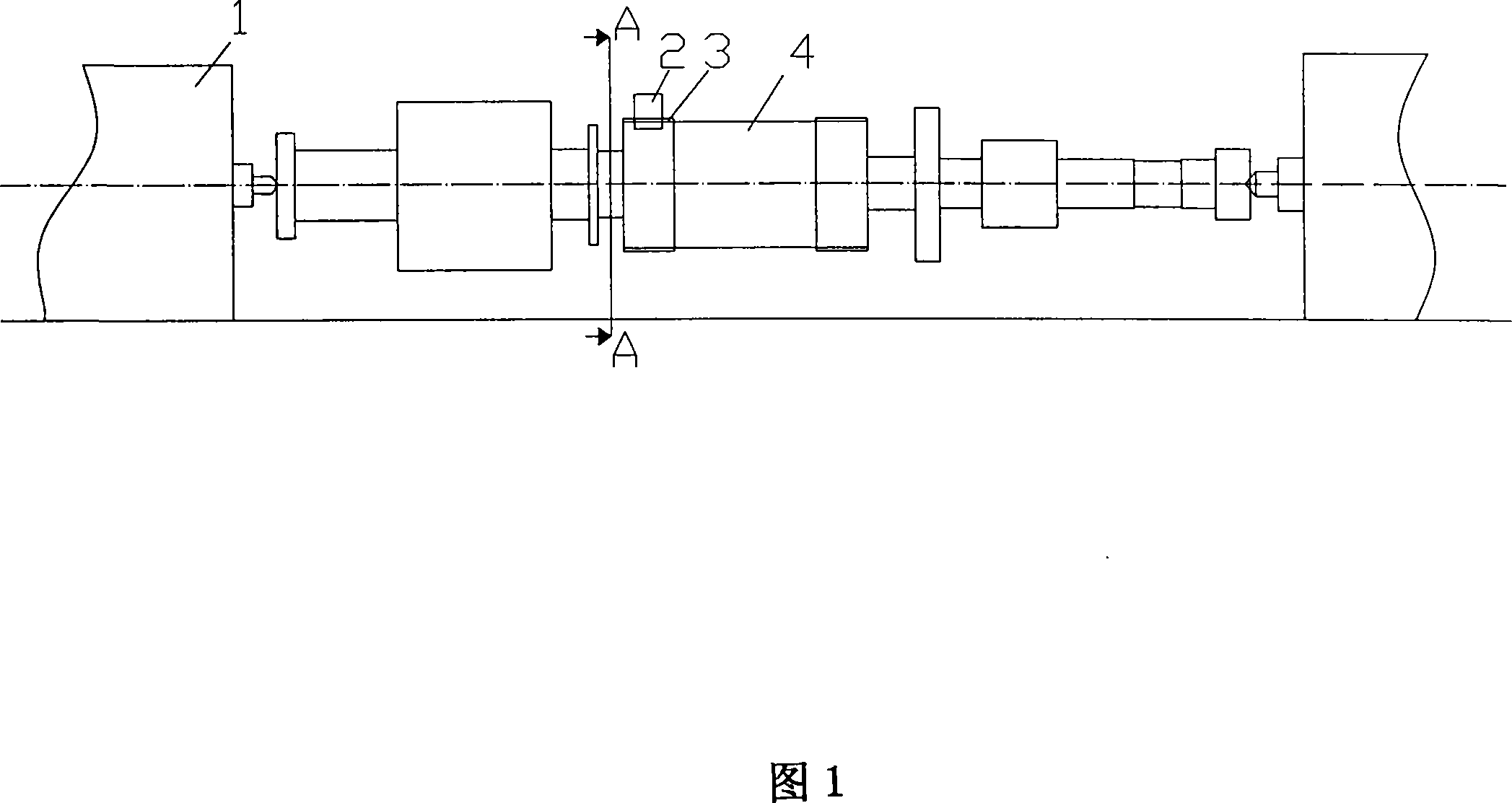

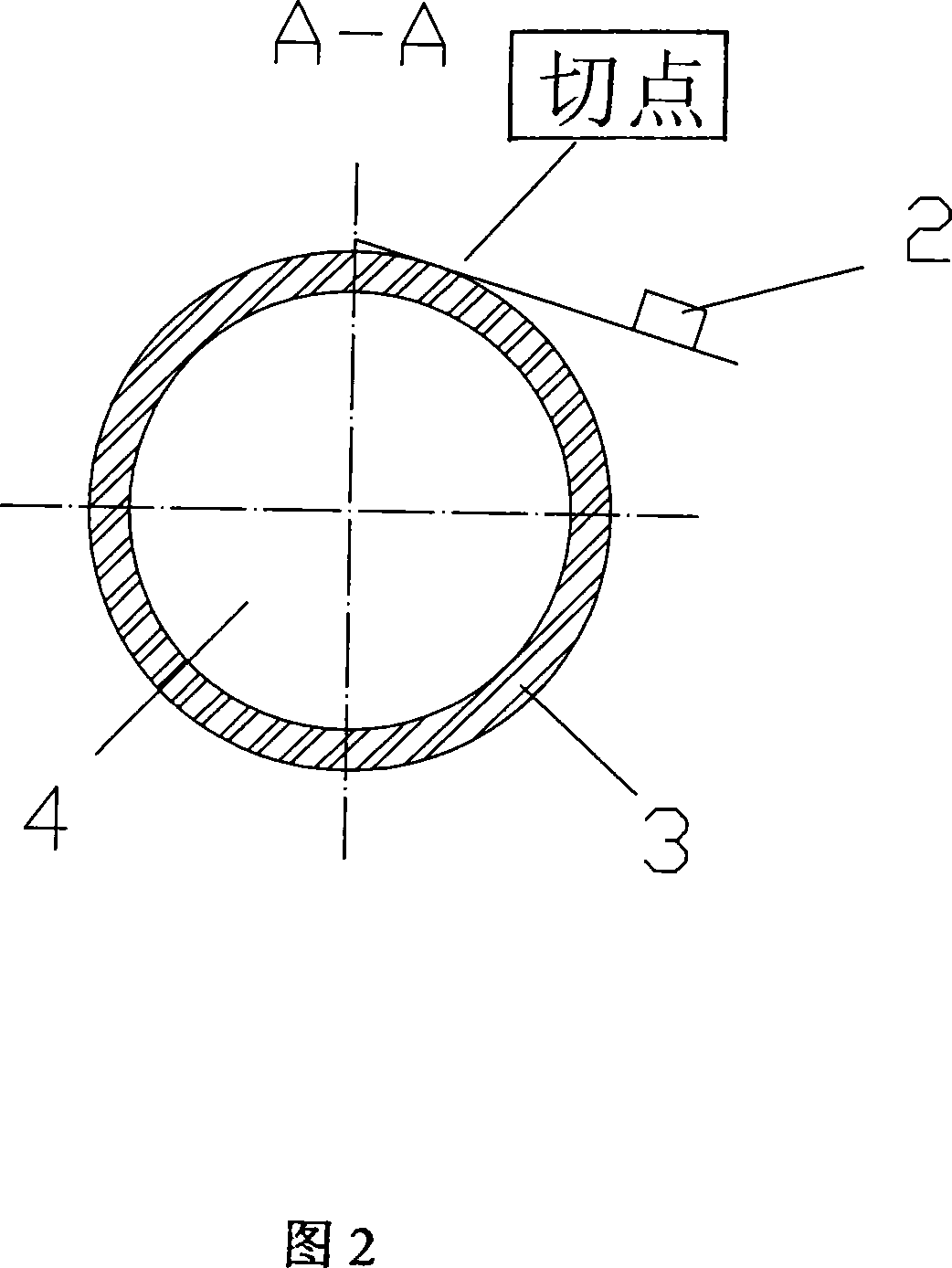

[0023] As shown in Figure 1, it is a schematic diagram of a method for wrapping a latitude-free tape at the end of a rotating electric machine. A method for wrapping a latitude-free tape at the end of a rotating electric machine is as follows:

[0024] The first step. Install the armature 4 on the machine tool 1;

[0025] The second step. Bind the non-weft tape 3 while rotating at the end of the armature 4 coil;

[0026] Step 3. Use the hot air blower 2 to directly heat the latitude-free tape 3 .

[0027] One principle is followed in actual operation: the heat received by the weft belt per unit time. In order to ensure the feasibility and convenience of the process, the following constant can be established: Q. to deal with different equipment. Also set: T-Temperature °C, that is, hot air outlet or other heat sources, V---Linear speed m / min, that is, tape linear speed or indirectly converted from rotational speed to linear speed. Let the ratio of T and V be a constant Q=T / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com