Circular knitting machine and electric motor

A circular knitting machine and electric motor technology, applied in the field of electric motors, can solve problems such as affecting the quality of knitted fabrics, endangering the working safety of the circular knitting machine, transmission interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

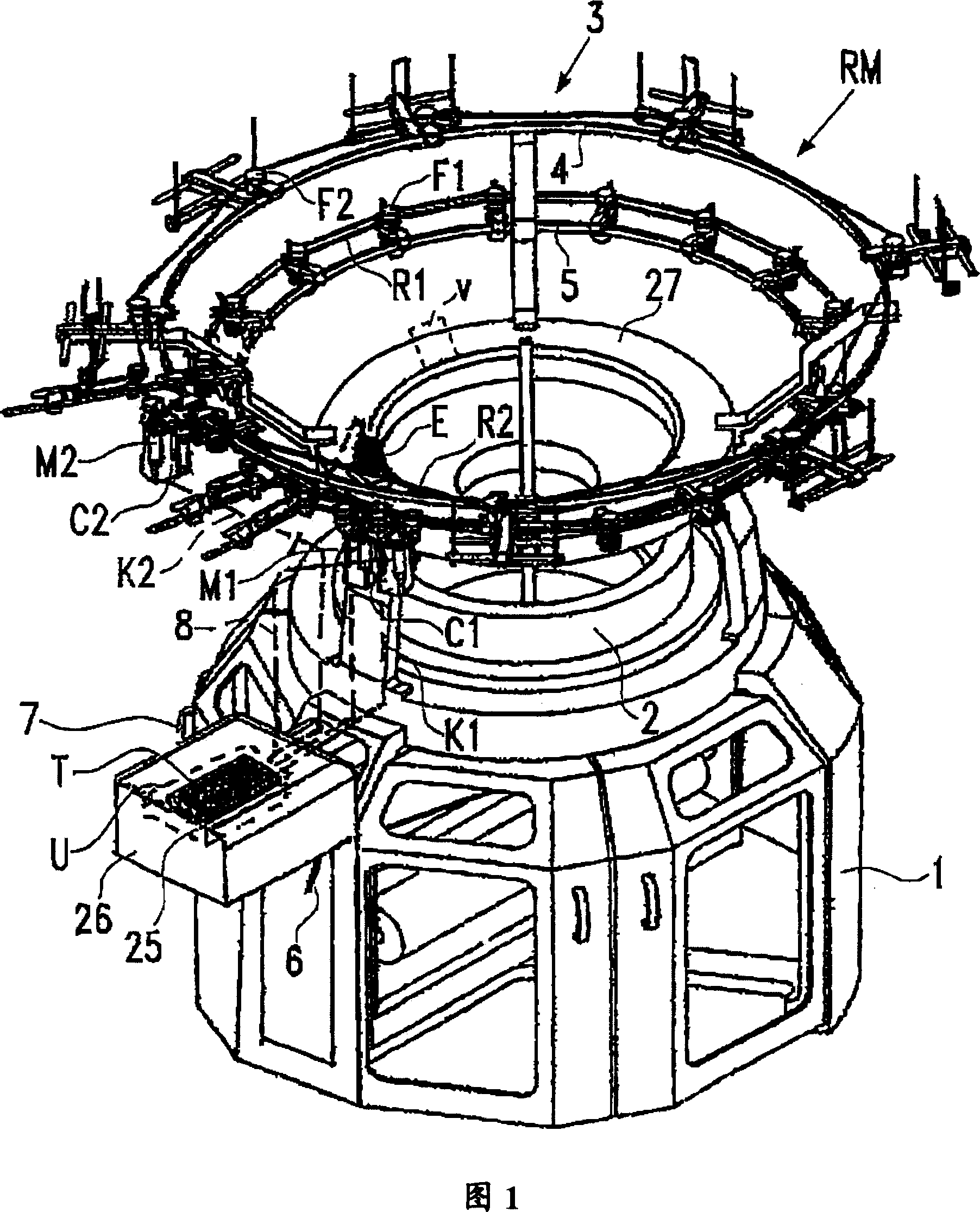

[0020] Fig. 1 schematically depicts a circular knitting machine RM represented only by basic elements. The circular knitting machine RM is situated on the ground with eg a polygonal base 1 and comprises a needle cylinder 2 on top of which a feeder carrying system 3 is arranged. Several yarn feeding devices F1, F2 of the same type or of different types are fixed on the carrier rings 4, 5 and integrated into the respective belt drives R1, R2. The belt drives driving the integrated yarn feeding devices F1, F2 are driven by at least one electric motor M1, M2.

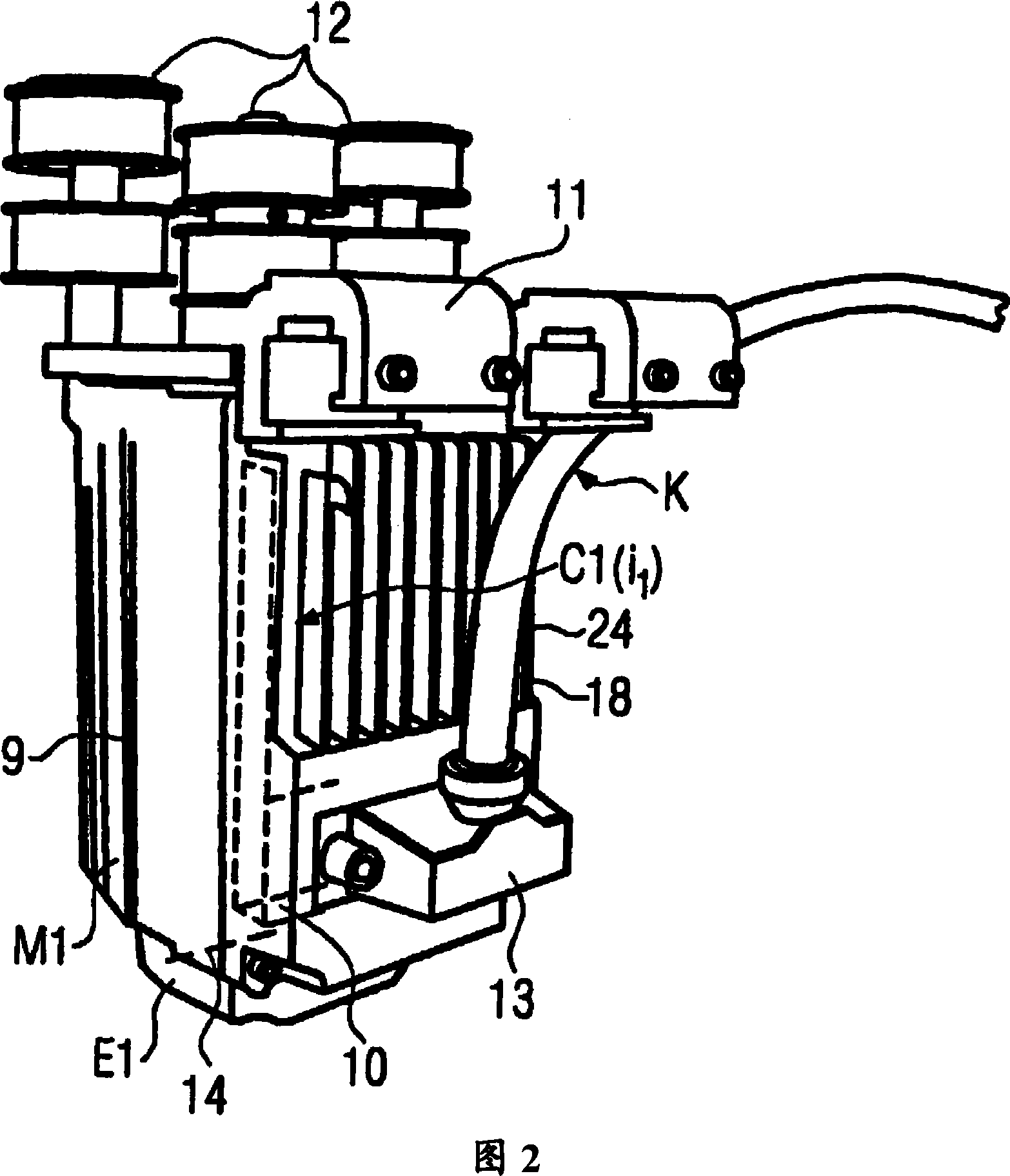

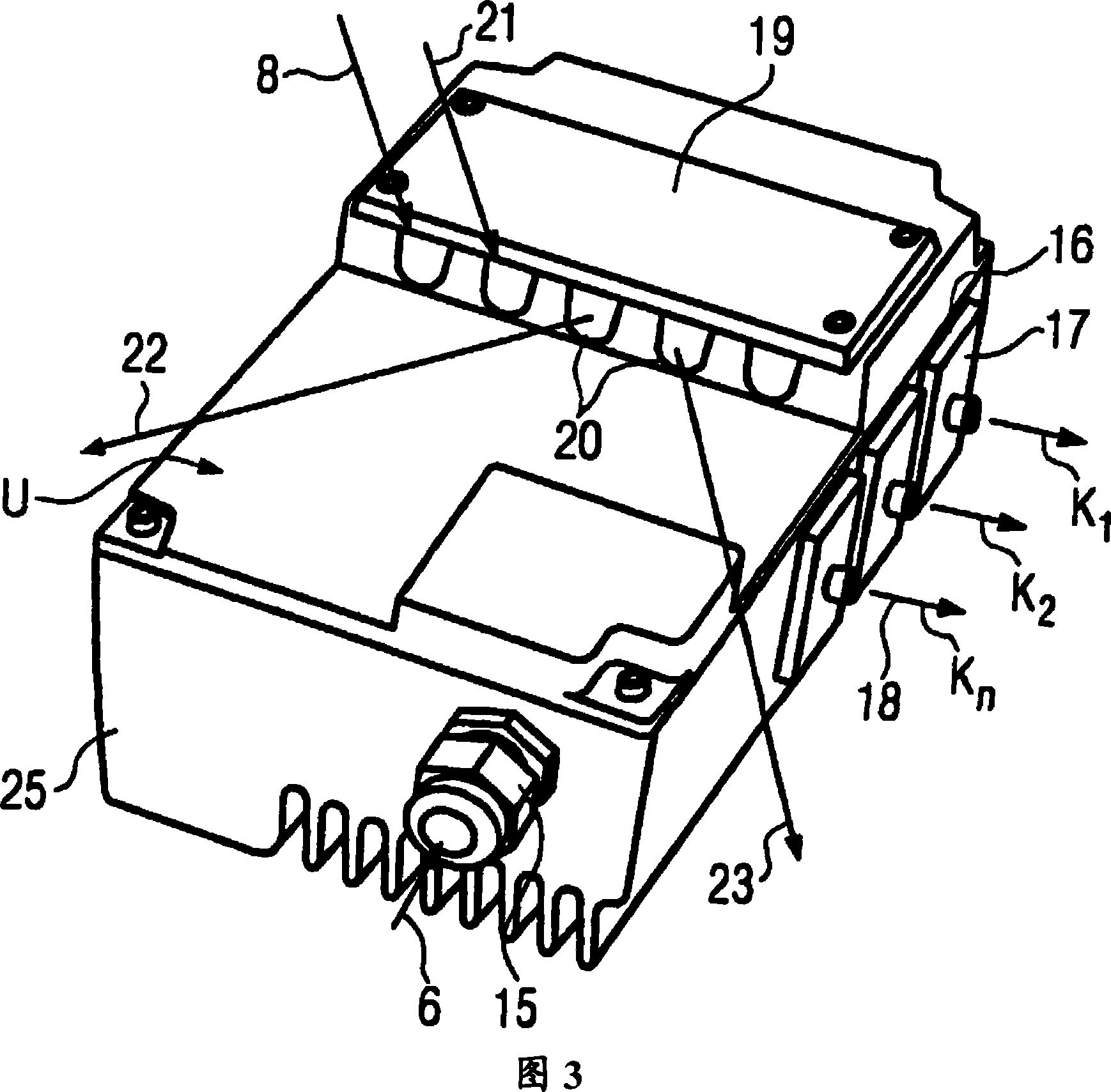

[0021] The motors M1 , M2 are for example permanent magnet motors, ie synchronous alternating current or AC motors. A speed controller C1, C2 with control circuit and power circuit (Fig. 2) is integrated into each motor. The electric motors M1, M2 are connected to the interface unit U via cable strands K1, K2. The interface unit U is generally used for all electric motors and is mounted, for example, on the base 1 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com