Measuring device and method for transparent substance and reflector based on digital microscope and data synthetic technique

A technology of digital micromirrors and transparent objects, applied in measurement devices, optical devices, instruments, etc., can solve problems such as moving workbenches, errors, system complexity, etc., to simplify system structure, improve measurement dynamics, and improve system measurement. The effect of resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

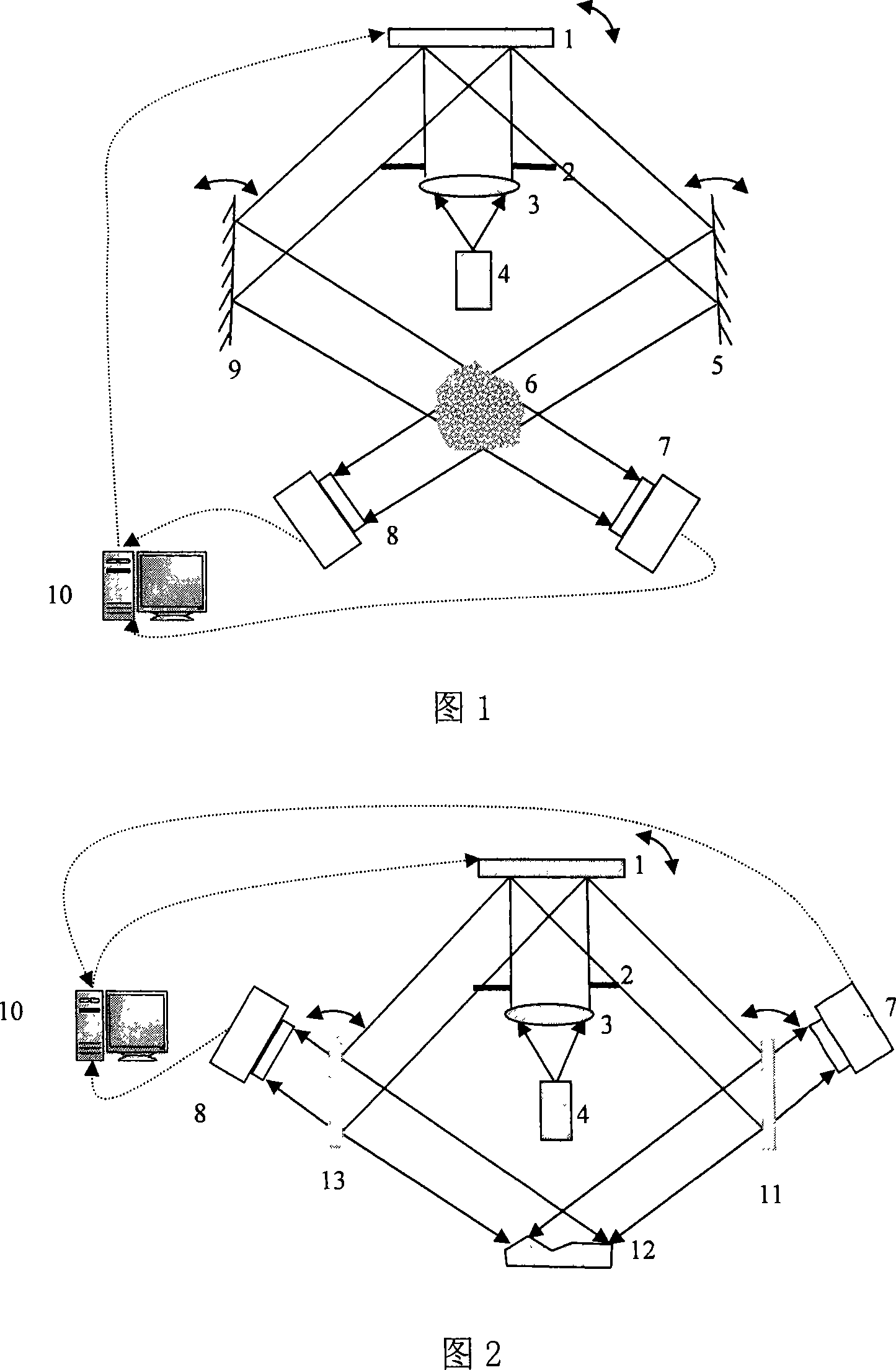

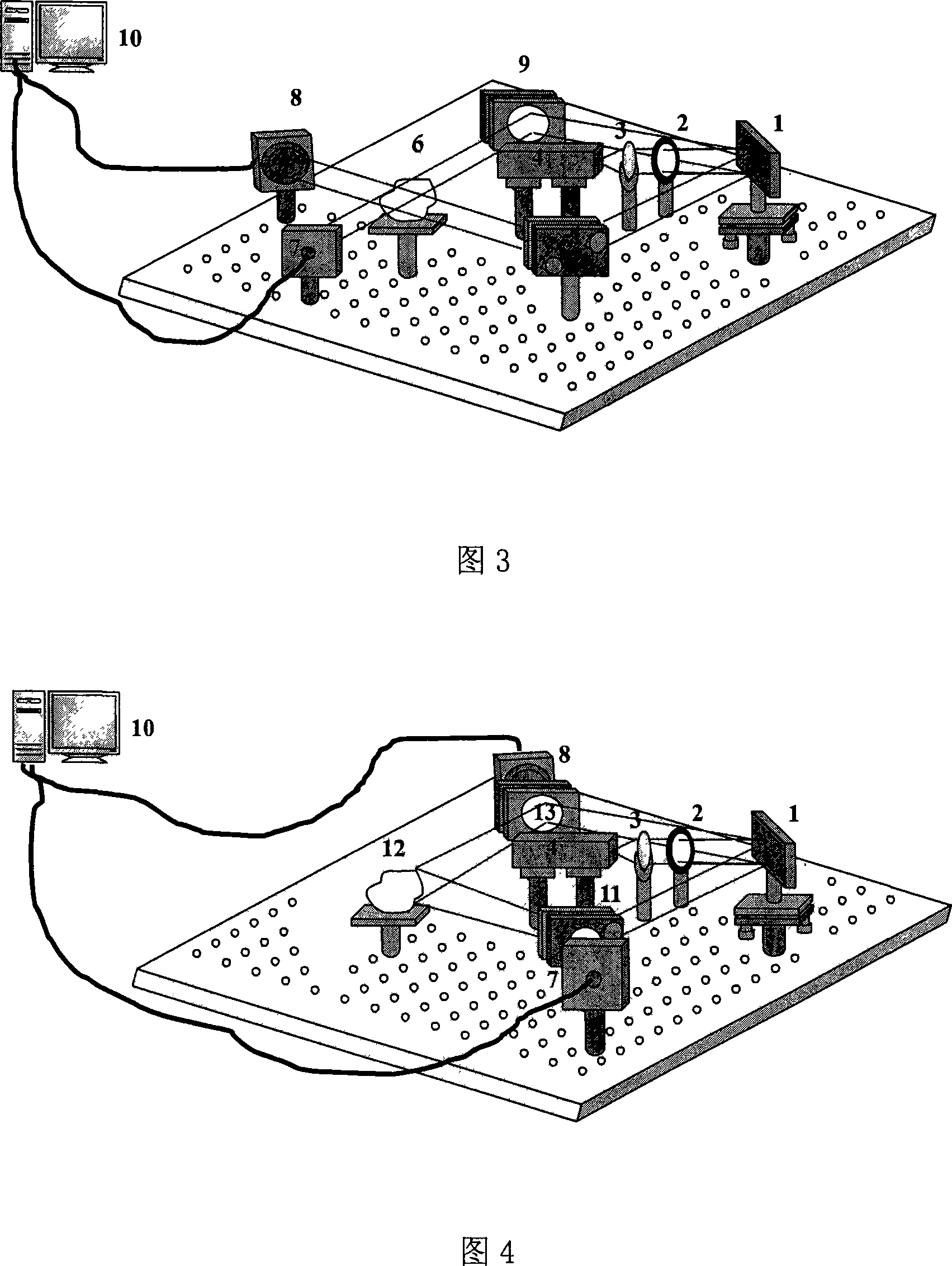

[0018] Preferred embodiment of the present invention is described in detail as follows in conjunction with accompanying drawing: A preferred embodiment that the present invention is used for transparent object measurement is: referring to Fig. 1 and Fig. 3, semiconductor laser 4 emits laser light source and becomes collimated light source after collimating lens 3 , projected onto the digital micromirror 1, adjust the digital micromirror bracket to generate two beams of horizontal conjugate reflected light: one beam passes through the mirror 5, adjust the mirror frame so that the reflected beam is projected onto the transparent object 6 to be measured, and then transmitted to the CCD8 Receive; the other beam passes through the reflector 9, adjust the reflector frame so that the reflected beam is projected onto the transparent object 6 to be measured, and transmitted to the CCD7 for reception. CCD7 and CCD8 simultaneously transmit the collected data to computer 10 for data proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com