Chip detection method

A detection method and wafer technology, which are applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of reduced production efficiency, false alarms, and increased production costs, so as to reduce the number of false alarms, reduce production costs, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

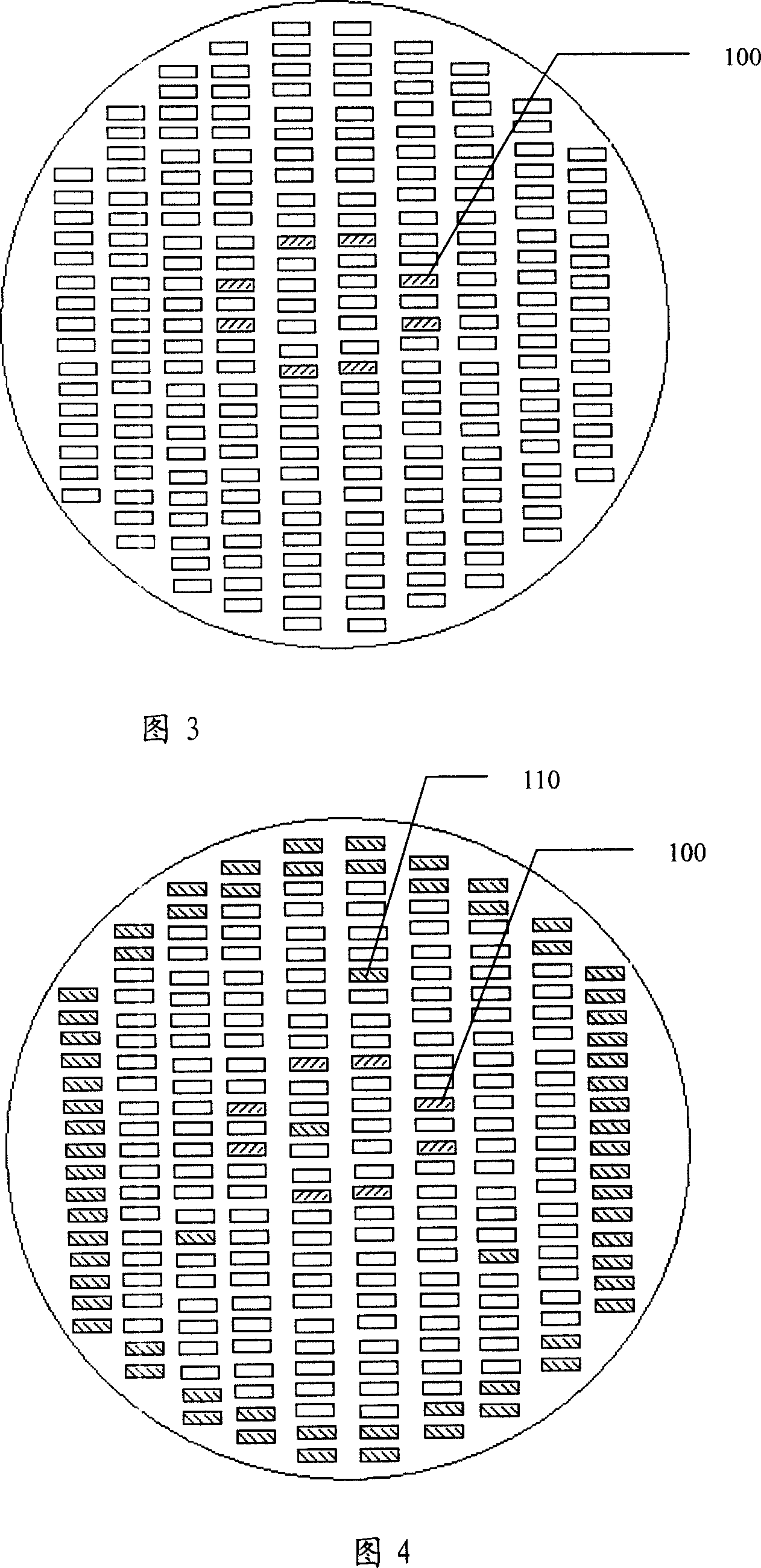

[0048] The wafer inspection method provided by the present invention includes: acquiring an optical image of the wafer; performing grayscale calculation on the optical image of the wafer and performing partitioning; determining the standard chip in the partition; comparing the grayscale values of other chips in the partition with the standard chip , if the comparison result exceeds the allowable range, it is detected that the chip is a defective chip.

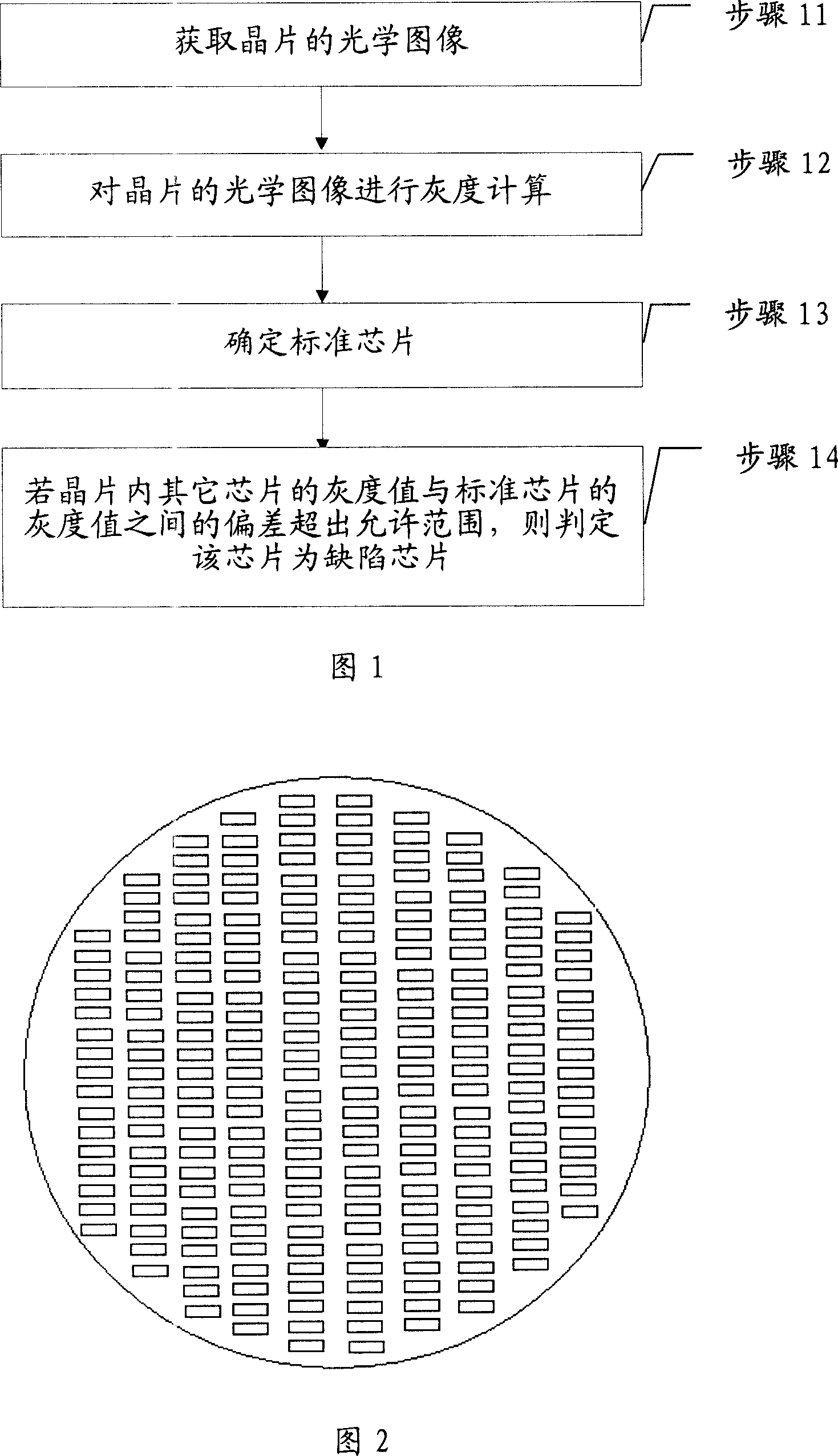

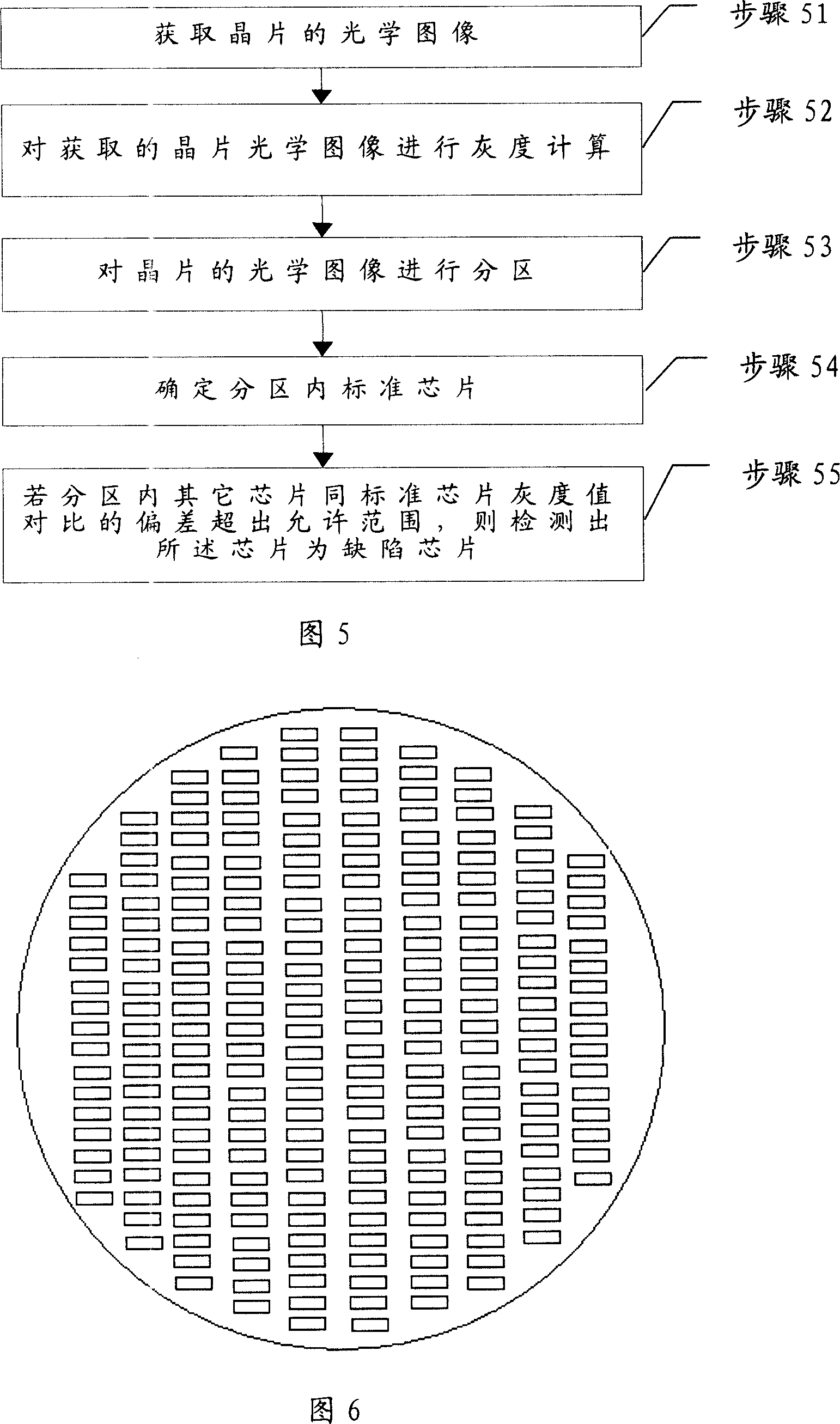

[0049] Fig. 5 is a schematic diagram illustrating the automatic visual inspection process of the embodiment of the present invention. As shown in Fig. 5, the automatic visual inspection process of the first embodiment of the present invention is:

[0050] Step 51: Using the optical pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com