Wall-climbing robot on surface of iron based tank

A wall-climbing robot and body surface technology, applied in the field of intelligence, can solve problems such as insufficient measurement accuracy and large measurement errors, and achieve the effects of simple structure, convenient operation, and small errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

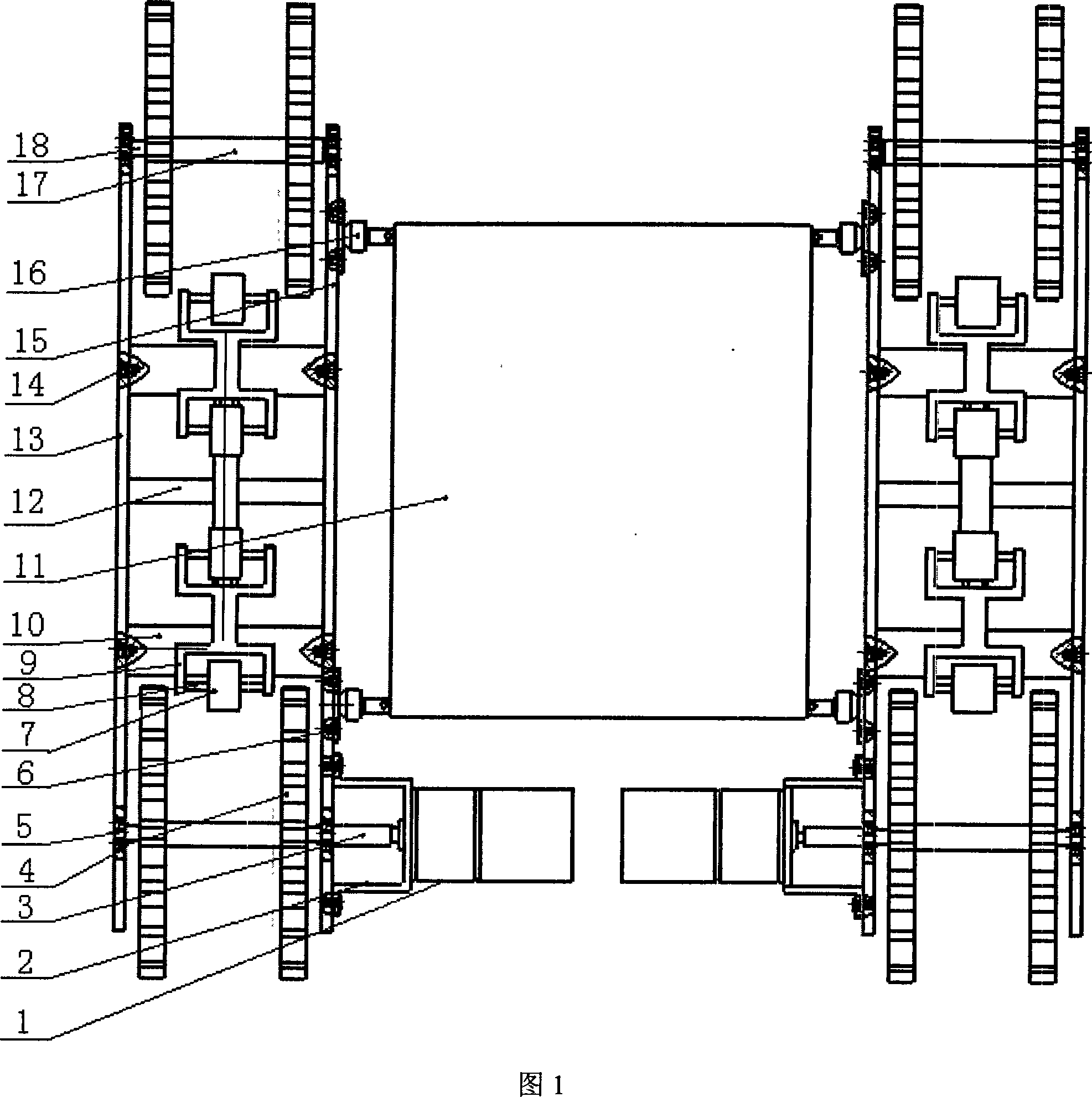

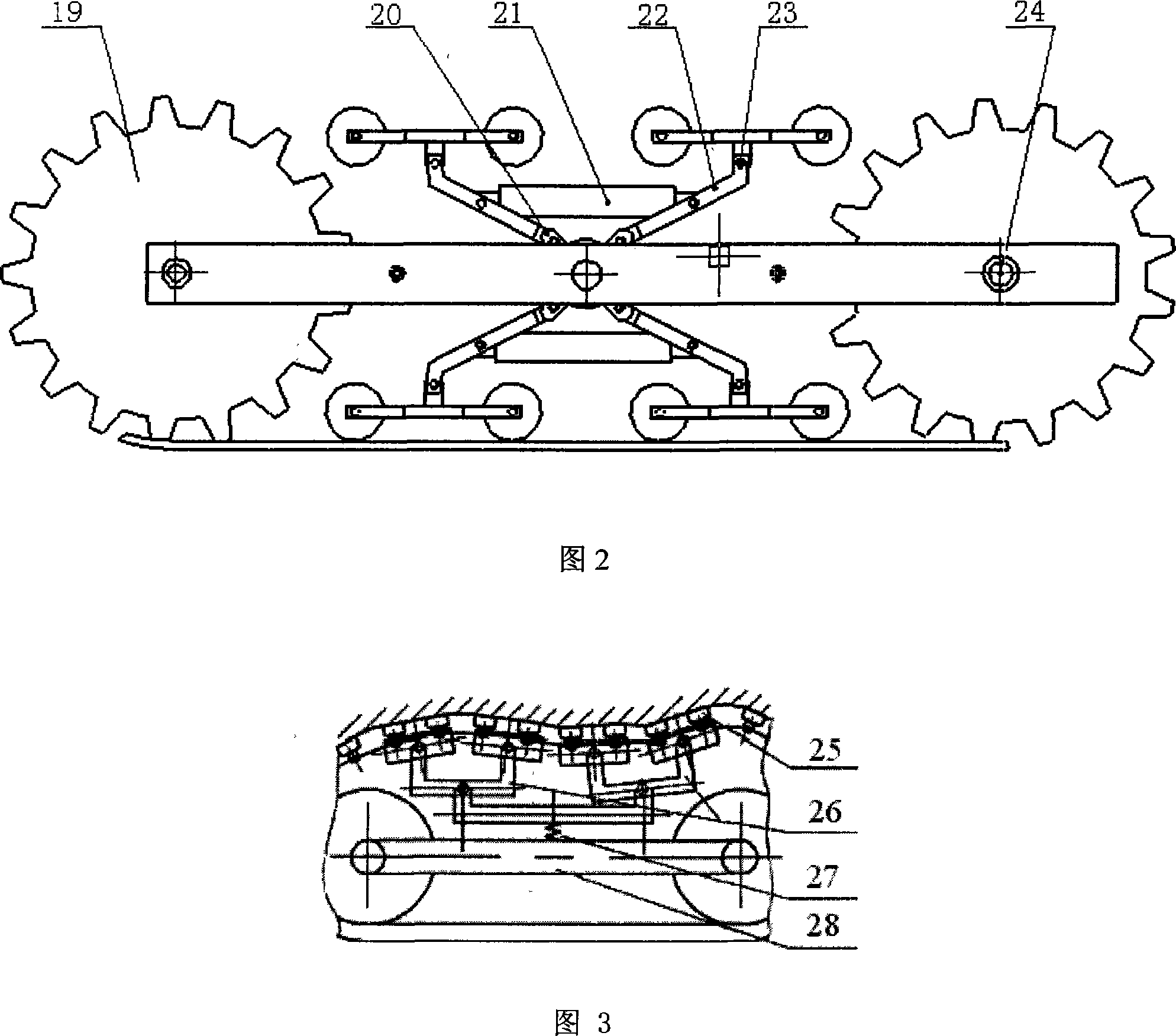

[0011] Embodiment: As shown in Fig. 1, Fig. 2 and Fig. 3, it includes a reduction motor 1, a sprocket 4, a chain crawler, a motor fixing mechanism 2, a coupling 3, a tensioner 7, a tensioner shaft 8, and a sprocket bracket C10, tension small shaft 12, spherical hinge 16, axle sleeve 17 form. The sprocket support A13, the sprocket support B15 and the sprocket support C10 are connected together with countersunk screws 14 to form a crawler frame 28, and the reduction motor 1 is fixed on the sprocket support B15 with the countersunk screws 6 through the motor fixing mechanism 2. Output shaft drives sprocket wheel 4 through shaft coupling 3, driving wheel shaft 24, and sprocket wheel 4 is installed on the track wheel frame through sprocket wheel shaft 18, bearing 5, axle sleeve 17, and two sprocket wheels 4 are connected with chain 19. Tensioning mechanism 9 is made up of tensioning frame 20, tensioning small shaft 12, tensioning wheel plate 22, pin 23, rigid guide rod 26, spring 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com