Pump type displacement correlated damping shock absorber

A variable damping and shock absorber technology, which is applied in the direction of shock absorbers, liquid shock absorbers, shock absorbers, etc., can solve the problem that the vibration damping performance of the shock absorber cannot be adjusted, the shock and vibration cannot be suppressed, and random automatic adjustment cannot be made. and other problems to achieve the effect of avoiding premature failure, good vibration reduction effect and sensitive vibration response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

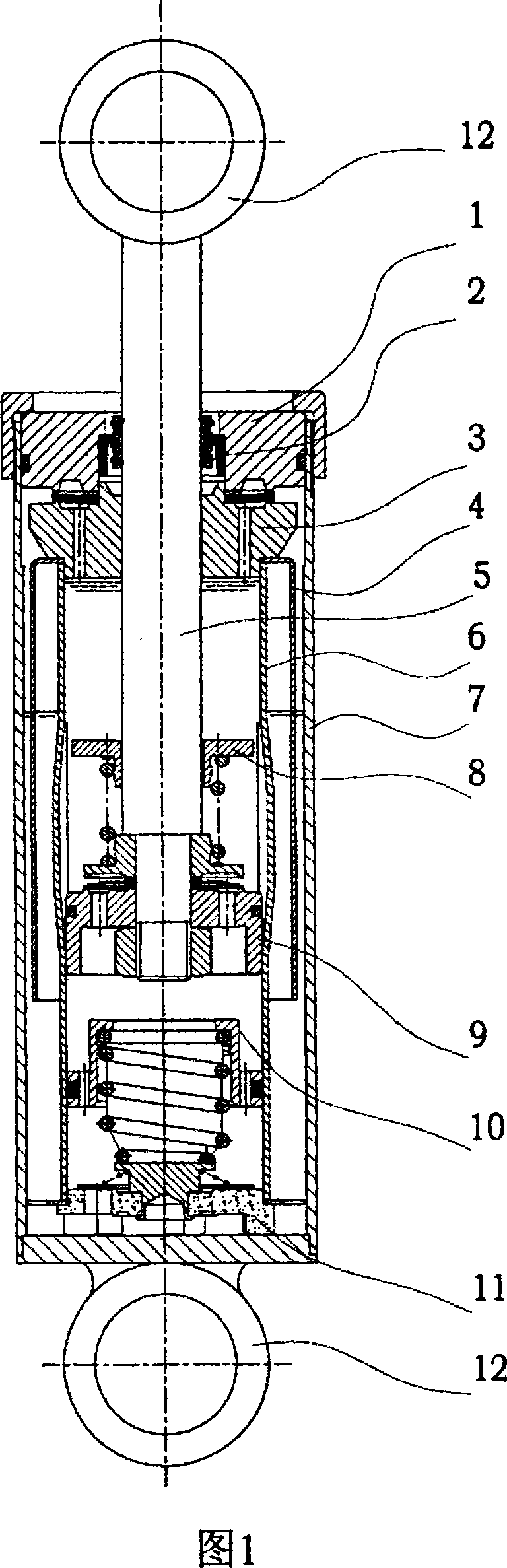

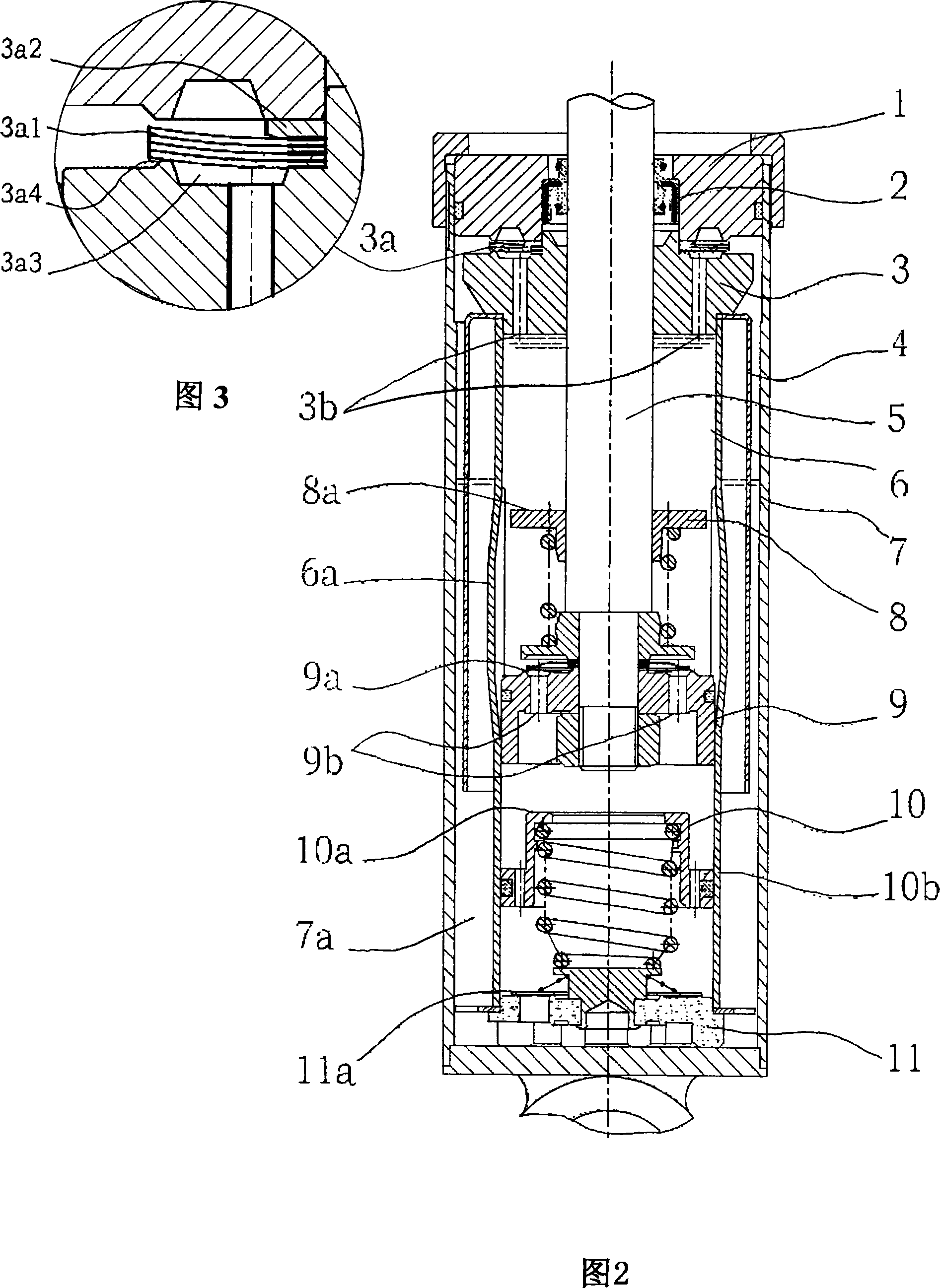

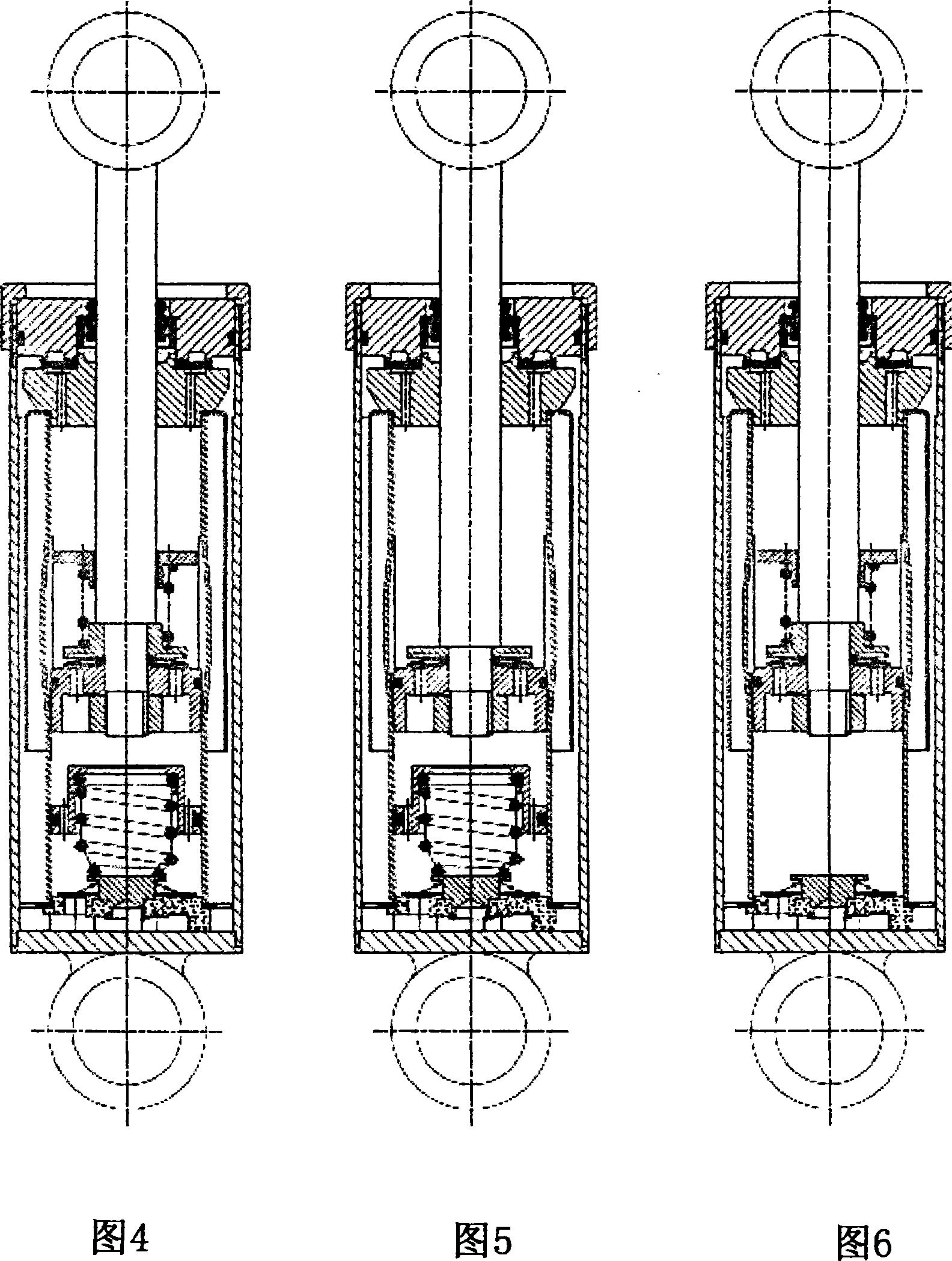

[0020] Referring to Fig. 4, it is embodiment 1 of the present invention, shows in the figure that upper limiter 8 and lower limiter 10 can be configured simultaneously, and are placed on the upper and lower positions of piston 9 respectively.

[0021] Referring to Fig. 5, it is embodiment 2 of the present invention, shows in the figure that upper limiter 8 can be separately configured on the top of piston 9.

[0022] Referring to FIG. 6 , it is Embodiment 3 of the present invention, which shows that the lower limiter 10 can be separately configured at the lower part of the piston 9 near the bottom valve seat.

[0023] The upper limiter 8 in the present invention comprises corresponding spring seats up and down, and a pressure spring is housed between the two spring seats for buffering when the piston moves upwards quickly. The lower limiter 10 includes an upper spring seat and a lower spring seat, and a pressure spring is installed between the two spring seats for buffering wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com