Liquid crystal tropism agent and liquid crystal display element

A technology of liquid crystal display element and liquid crystal aligning agent, which is applied in the direction of liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of pretilt angle deviation and display quality degradation, and achieve high pretilt angle, good orientation uniformity, and printing Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0116] Hereafter, although an Example demonstrates this invention more concretely, this invention is not limited to these Examples. In the examples and comparative examples, the pretilt angle, uniformity of the pretilt angle, voltage retention rate, and printing were evaluated by the following methods.

[0117]

[0118] According to the method described in T.J.Scheffer et al., J.Appl.Phys., Vol.19, 2013 (1980), it measured by the crystal rotation method using a He-Ne laser. At this time, in the same process, six liquid crystal display elements manufactured using an alignment agent were measured, and the average value was obtained from the following formula, and used as the pretilt angle of the liquid crystal display element.

[0119] The pretilt angle of the liquid crystal display element = (the measured value of the pretilt angle of the first liquid crystal display element + the measured value of the pretilt angle of the second liquid crystal display element + the measured ...

Synthetic example 1

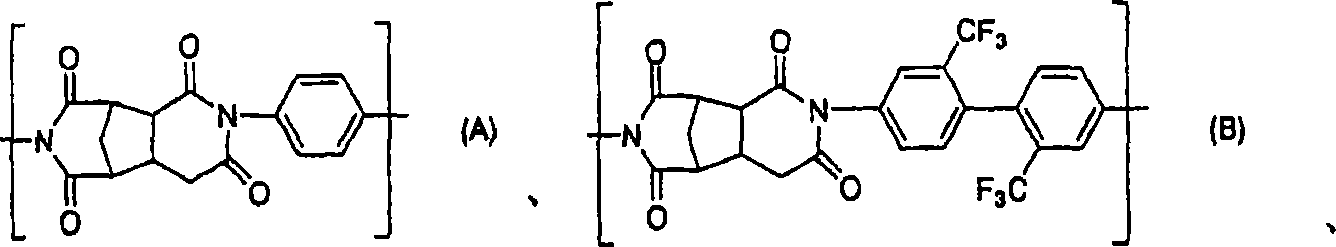

[0133]112.09 g (0.5 mol) of 2,3,5-tricarboxycyclopentylacetic dianhydride as tetracarboxylic dianhydride and 1,3,3a,4,5,9b-hexahydro-8-methyl-5 -(tetrahydro-2,5-dioxo-3-furyl)-naphthalene[1,2-c]-furan-1,3-dione 157.14g (0.5 moles), as the p- 55.42 g (0.5125 mol) of phenylenediamine, 128.09 g (0.4 mol) of 2,2'-trifluoromethyl-4,4'-diaminobiphenyl, and 35.07 g (0.08 mol) of the compound represented by the above formula (22) 1.4 g (0.015 mol) of aniline as a monoamine was dissolved in 1140 g of N-methyl-2-pyrrolidone, and reacted at 60° C. for 6 hours to obtain a polyamide with a shear viscosity of 9.7 mPa·s at 5.0% by weight. Amic acid. Add 3256g of N-methyl-2-pyrrolidone, 316.4g of pyridine and 408.4g of acetic anhydride to the obtained polyamic acid, dehydrate and close the ring at 110°C for 4 hours, concentrate under reduced pressure with an evaporator, and distill off the catalyst and solvent. Dilute with gamma-butyrolactone to obtain 4800 g of 5.0% by weight under the she...

Synthetic example 2

[0135] 112.09 g (0.5 mol) of 2,3,5-tricarboxycyclopentylacetic dianhydride as tetracarboxylic dianhydride and 1,3,3a,4,5,9b-hexahydro-8-methyl-5 -(tetrahydro-2,5-dioxo-3-furyl)-naphthalene[1,2-c]-furan-1,3-dione 157.14g (0.5 moles), as the p- 55.42 g (0.5 125 mol) of phenylenediamine, 133.7 g (0.4 mol) of 2,2-bis(4-aminophenyl) hexafluoropropane, and 41.83 g (0.08 mol) of the compound represented by the above formula (16), as a single 1.4 g (0.015 mol) of aniline as an amine was dissolved in 1170 g of N-methyl-2-pyrrolidone and reacted at 60° C. for 6 hours to obtain a polyamic acid having a shear viscosity of 10.2 mPa·s at 5.0% by weight. Add 3340g of N-methyl-2-pyrrolidone, 316.4g of pyridine and 408.4g of acetic anhydride to the obtained polyamic acid, dehydrate and close the ring at 110°C for 4 hours, concentrate under reduced pressure with an evaporator, distill off the catalyst and solvent, and use Gamma-butyrolactone was released to obtain 5000 g of polyimide with a sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com