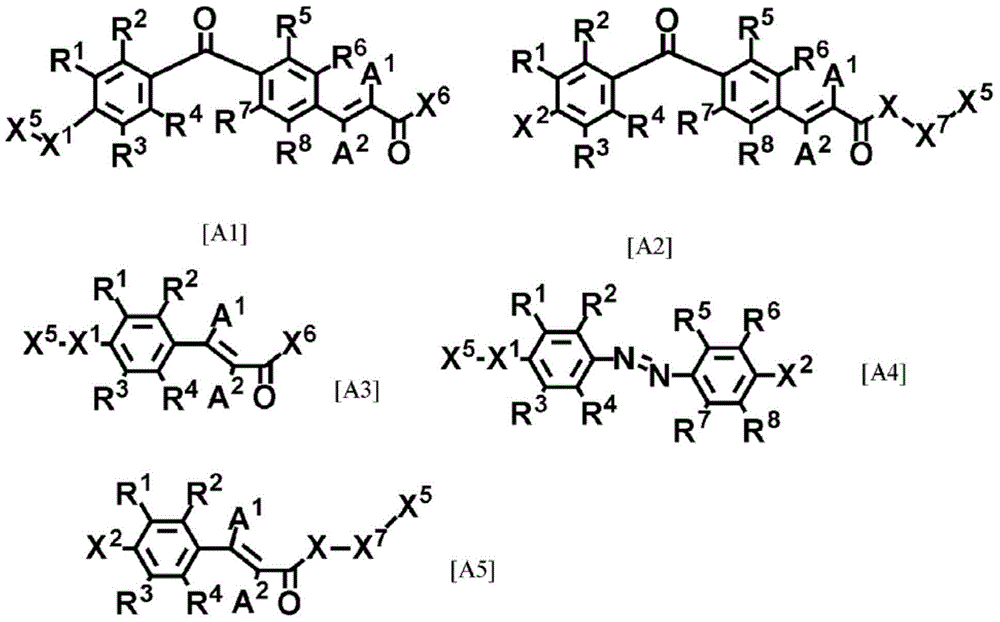

Composition for forming cured film, alignment material, and phase difference material

A technology for curing films and compositions, applied in photosensitive materials for optomechanical equipment, instruments, optics, etc., can solve problems such as recording, and achieve the effects of excellent orientation uniformity and excellent orientation sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

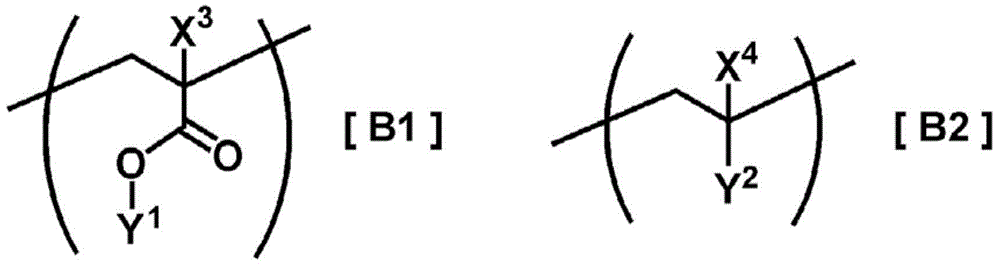

Method used

Image

Examples

Embodiment

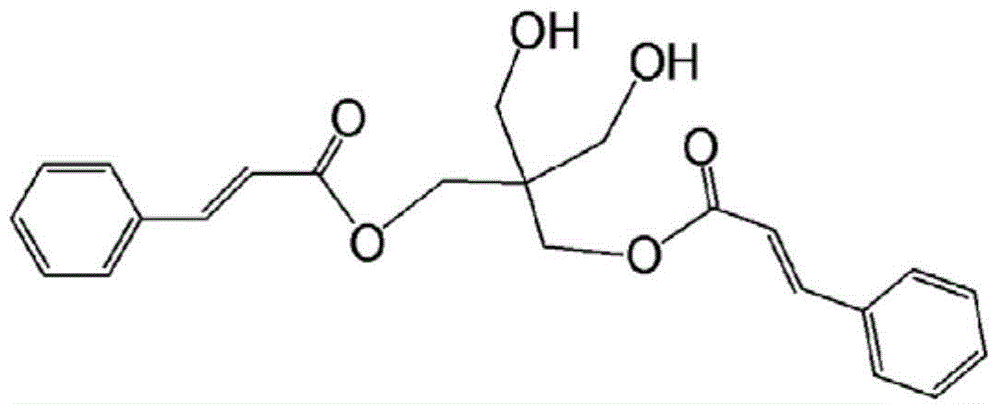

[0163] Hereinafter, although an Example is given and this embodiment is demonstrated in more detail, this embodiment is not limited to these Examples.

[0164] [Abbreviated symbols used in Examples]

[0165] The meanings of the abbreviations used in the following examples are as follows.

[0166]

[0167] CIN1: Methyl 4-Hydroxyhexyloxycinnamate

[0168] CIN2: Methyl 3-methoxy-4-hydroxyhexyloxycinnamate

[0169]

[0170] MAA: methacrylic acid

[0171] MMA: methyl methacrylate

[0172] HEMA: 2-Hydroxyethyl methacrylate

[0173] AIBN: α,α'-Azobisisobutyronitrile

[0174] PCTO: polycaprolactone triol (molecular weight 500)

[0175] HPCEL: Hydroxypropyl Cellulose

[0176] PHEM: polyhydroxyethyl methacrylate (25% by weight PM solution)

[0177] PEPO: polyester polyol (adipic acid / diethylene glycol copolymer) (molecular weight 4800)

[0178] PCDO: polycarbonate diol (Mw: 500)

[0179]

[0180] HMM: Hexamethoxymethylmelamine

[0181] BMAA: N-(butoxymethyl)acrylamide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com