Cured film, alignment material, and retardation material

A technology of cured film and photo-alignment, applied in the field of retardation materials, can solve the problems such as the reduction of liquid crystal alignment, and achieve the effects of excellent alignment uniformity, high efficiency and excellent alignment sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

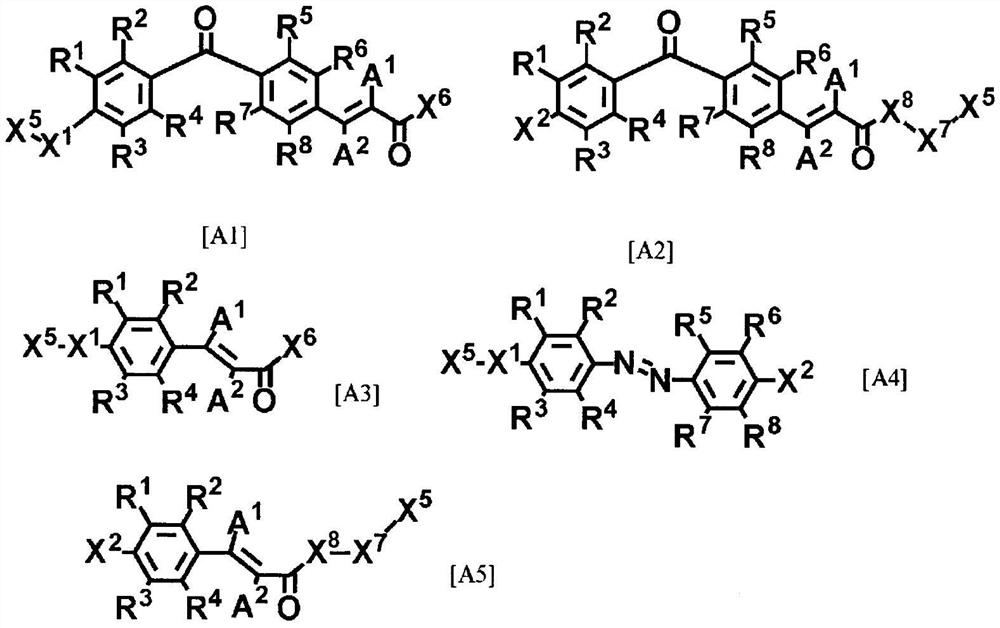

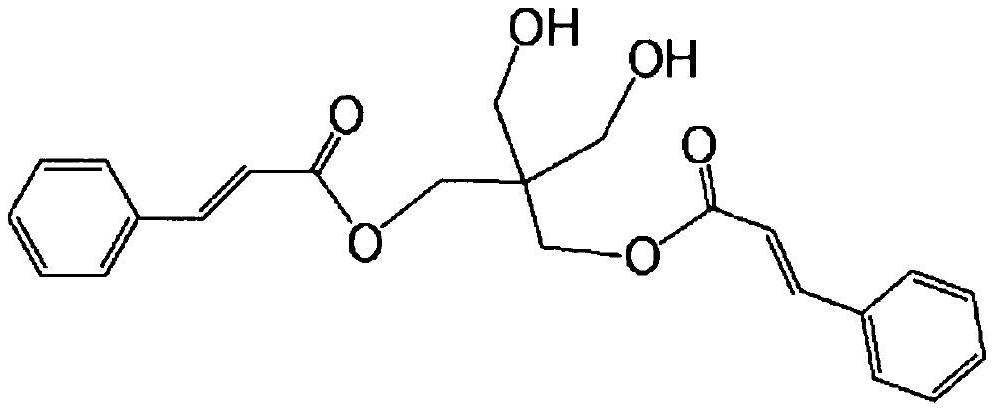

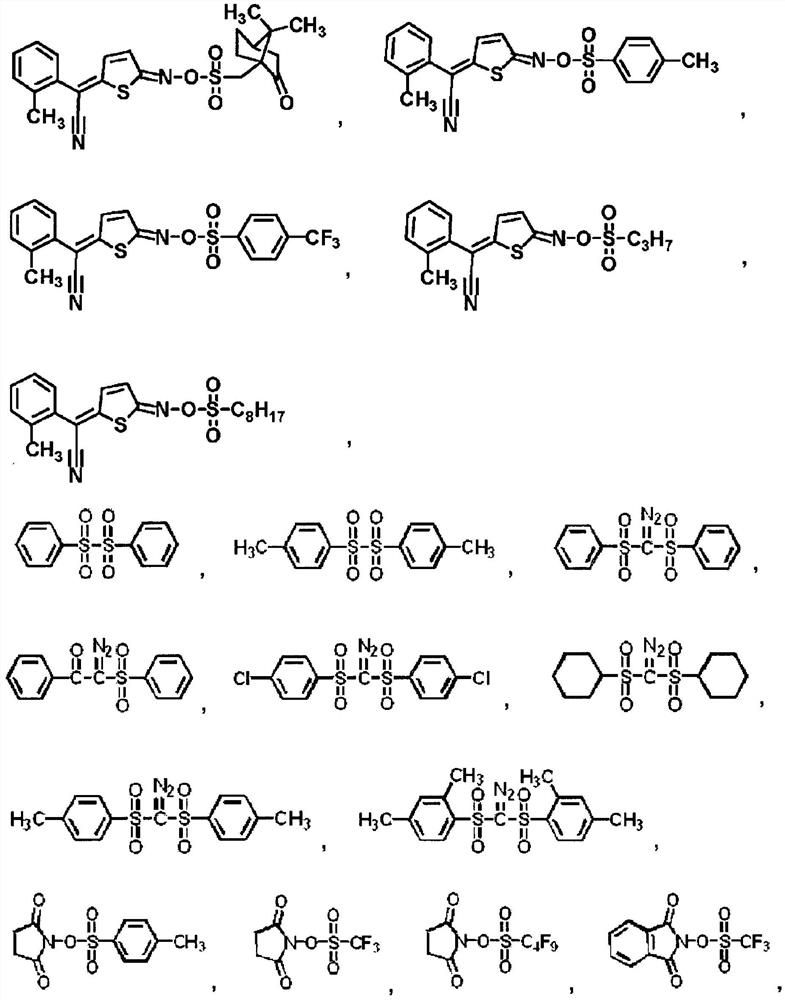

Method used

Image

Examples

Embodiment 1

[0169] 0.047 g of MCA as component (A), 0.065 g of APEPO-1 (RDK-133 manufactured by Kawasaki Chemical Industry Co., Ltd.) as component (B), and the polymer obtained in the polymerization example as component (C) (PC-1) 0.248g and 0.012g of PTSA which are (D)components were mixed, PM0.764g and BA0.984g were added as a solvent, and it was visually confirmed that it melt|dissolved, and the solution was obtained. Next, a liquid crystal aligning agent (A-1) was prepared by filtering the obtained solution through a filter with a pore size of 0.2 μm. In addition, here, a liquid crystal aligning agent and the composition for cured film formation have the same meaning.

Embodiment 2~ Embodiment 4

[0171] Except having used each component of the kind and compounding quantity shown in following Table 1, it carried out similarly to Example 1, and prepared each liquid crystal aligning agent (A-2) - (A-4).

[0172] APEPO-2: RFK-505 (manufactured by Kawasaki Chemical Industry Co., Ltd.)

[0173] APEPO-3: RFK-509 (manufactured by Kawasaki Chemical Industry Co., Ltd.)

[0174] APEPO-4: RMK-342 (manufactured by Kawasaki Chemical Industry Co., Ltd.)

Embodiment 5

[0183] Add 1.463g of LC-242 (manufactured by BASF Corporation) as a polymerizable liquid crystal for horizontal alignment, 0.029g of Irgacure907 (manufactured by BASF Corporation) as a photoradical initiator, and 0.075g of BYK-361N as a leveling material, and further add as 2.776 g of N-methylpyrrolidone as a solvent was stirred for 2 hours, and it was confirmed visually that it was dissolved, and a 30% by mass polymerizable liquid crystal solution LC-1 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com