Method for producing cholesteric liquid crystal display, cholesteric liquid crystal display, and liquid crystal aligning agent

A liquid crystal display and liquid crystal alignment agent technology, applied in the manufacture of cholesteric liquid crystal displays, cholesteric liquid crystal displays and liquid crystal alignment agents, can solve the problem that the uniformity of liquid crystal alignment cannot be called sufficient, and the ability of liquid crystal alignment has uniformity Low-level problems, to achieve the effect of promoting the improvement of productivity, improving the uniformity of orientation, and promoting the reduction of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0339] Hereinafter, the present invention will be described more specifically by way of examples, but the present invention is not limited to these examples. In addition, the necessary amounts of raw material compounds and polymers used in the following examples were ensured by repeating the synthesis of raw material compounds and polymers in the synthesis scheme shown in the following synthesis examples as needed.

[0340]

Synthetic example 1

[0342] In a reaction vessel with a stirrer, a thermometer, a dropping funnel and a reflux condenser, add 100.0 g of 2-(3,4-epoxycyclohexyl) ethyltrimethoxysilane (ECETS), 500 g of methyl iso Butanone and 10.0 g of triethylamine were mixed at room temperature. Next, 100 g of deionized water was dropped from the dropping funnel over 30 minutes, mixed under reflux, and reacted at 80° C. for 6 hours. After the reaction is over, take out the organic layer, use 0.2% by mass of ammonium nitrate aqueous solution to wash it until the water after washing is neutral, then distill off the solvent and water under reduced pressure to obtain a viscous transparent liquid with epoxy groups polyorganosiloxane.

[0343] The polyorganosiloxane with epoxy group is carried out 1 As a result of H-NMR analysis, an epoxy group-based peak with the same theoretical intensity was obtained around chemical shift (δ) = 3.2 ppm, thereby confirming that no side reaction of epoxy group occurred during the re...

Synthetic example 2

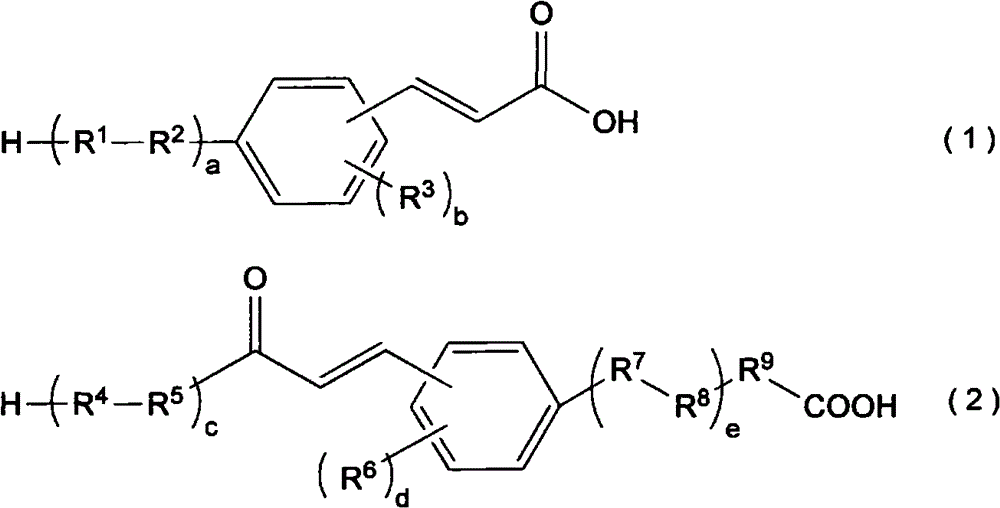

[0347] In a 300 mL three-necked flask with a condenser, mix 6.5 g of 4-fluorophenylboronic acid, 10 g of 4-bromocinnamic acid, 2.7 g of tetrakis(triphenylphosphine) palladium, 4 g of sodium carbonate, 80 mL of tetrahydrofuran and 39 mL of pure water . The reaction solution was continued to be heated and stirred at 80° C. for 8 hours, and the completion of the reaction was confirmed by TLC. After cooling the reaction solution to room temperature, it was poured into 200 mL of 1N-hydrochloric acid aqueous solution, and the precipitated solid was filtered. The obtained solid was dissolved in ethyl acetate, and liquid separation washing was performed in this order with 100 mL of 1N-hydrochloric acid aqueous solution, 100 mL of pure water, and 100 mL of saturated brine. Next, the organic layer was dried over anhydrous magnesium sulfate, and the solvent was distilled off. The obtained solid was vacuum-dried to obtain 9 g of a compound represented by the following formula (K-1) (spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com