Body of sulfur lamp with tuner

A tuner, sulfur lamp technology, applied in discharge lamps, electrical components, circuits, etc., can solve the problems of magnetron 6 damage, insufficient energy, magnetron 6 damage, etc., to reduce damage, prolong service life, shorten lighting time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

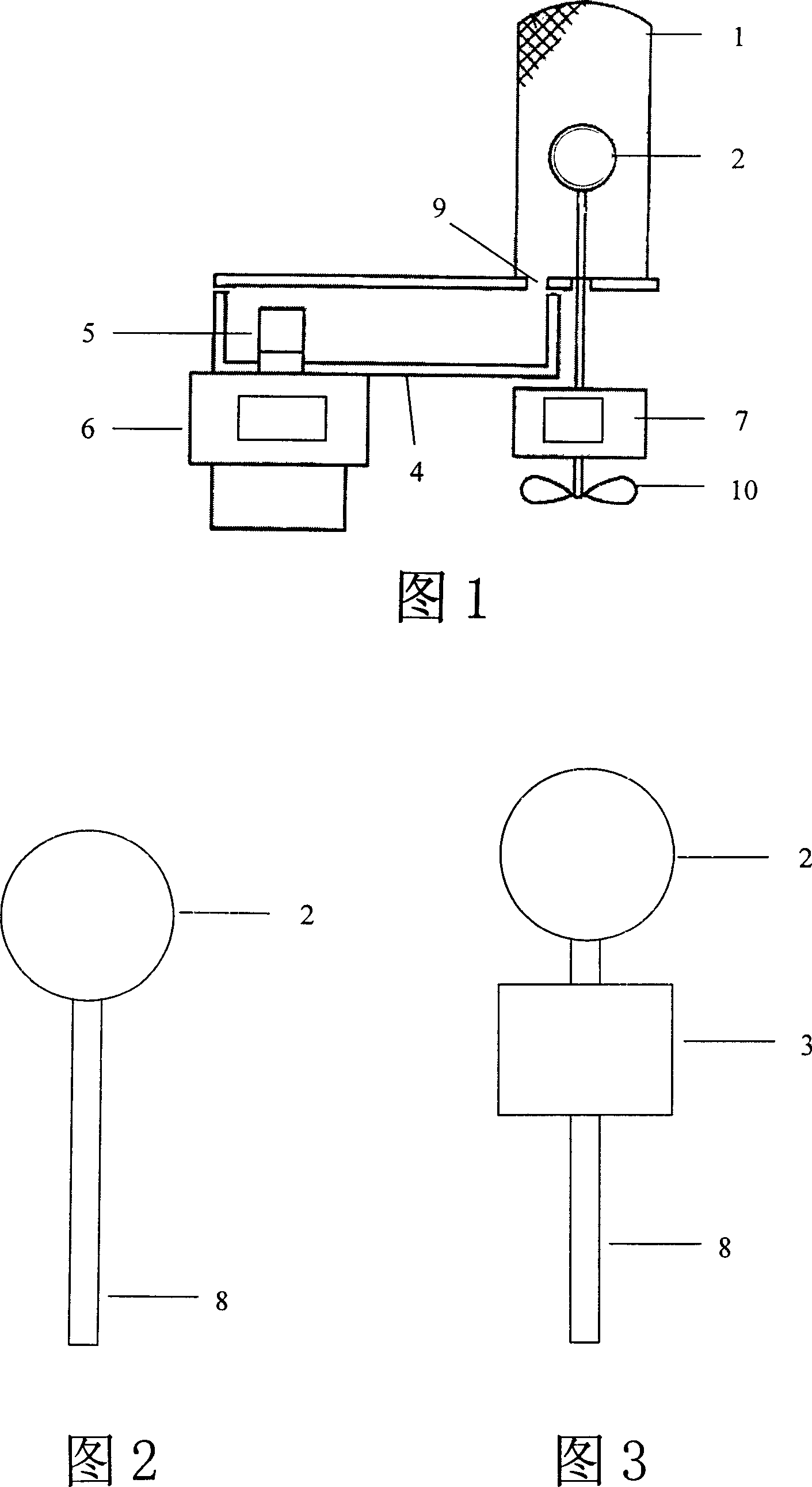

[0015] Referring to Fig. 3, the sulfur lamp body is formed by connecting the sulfur lamp bulb 2 and the lamp handle 8, and a cylindrical tuner 3 is installed on the lamp handle 8, the tuner 3 is hollow and made of quartz material. For different types of microwave sulfur lamp systems, due to the difference in output power and device size, correspondingly, the radius, thickness and position of the tuner 3 on the lamp handle will also be different, and its radius is between 20mm-40mm The thickness is between 25mm-30mm, and the distance between the upper surface and the sulfur lamp bulb 2 is 5mm-20mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com