Method for manufacturing semiconductor chips from wafers

A technology of conductor chips and semiconductors, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve problems such as expensive costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

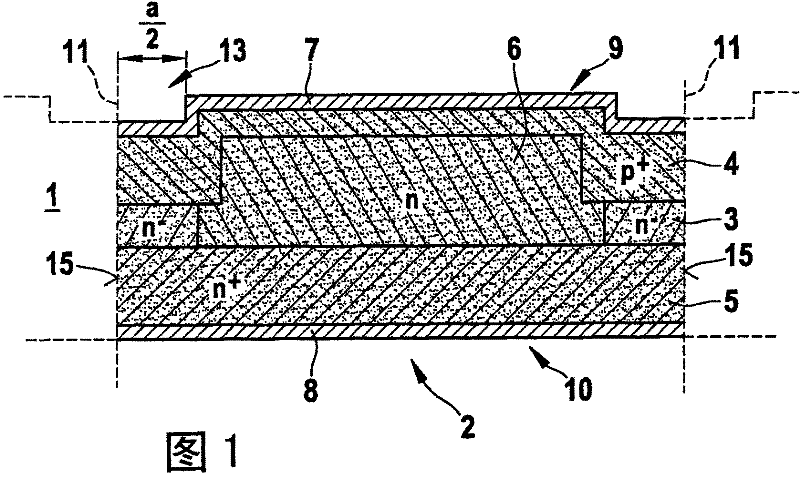

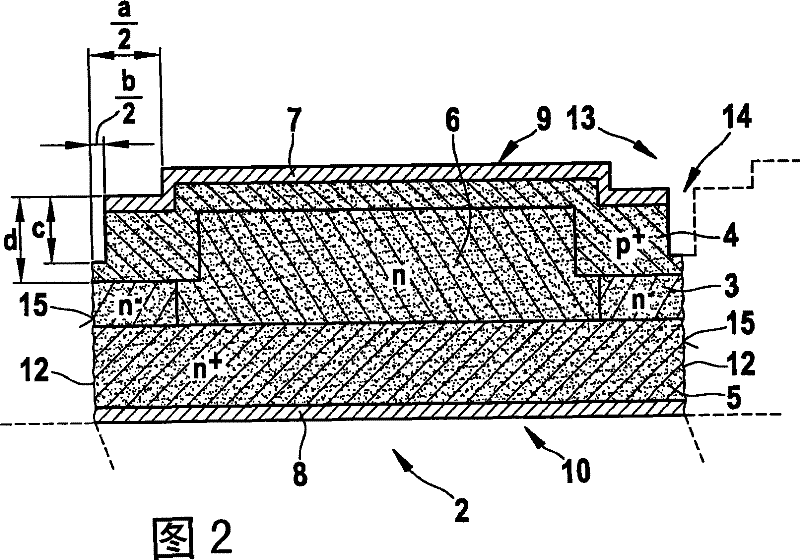

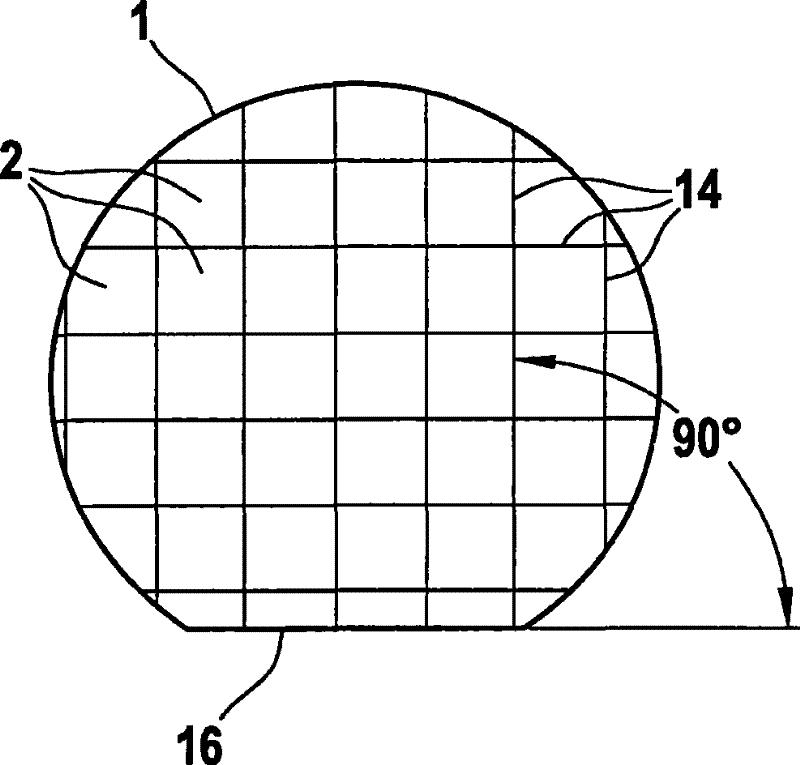

[0023] figure 1 Shown is a semiconductor chip 2 of a Zener diode (also known as a ZR diode) known from the prior art with reduced fringing field strength. The diode chip 2 is fabricated from a silicon substrate having, for example, approximately 8×10 15 cm -3 n doping. Viewed from the front side 9 to the back side 10, chip 2 contains p + Doped layer 4, an underlying n-doped substrate layer 6, which is laterally p-doped + doped layer 4 and the underlying weak n - Doped layer 3 surrounded, also has a strong n arranged on the backside 10 of the chip + Doped layer 5. In addition, a metallization layer 7 or 8 is applied to the front side 9 and the rear side 10 .

[0024] The ZR diode is distinguished in that breakdown occurs only in the center of the chip and not in the edge region of the diode chip 2 when operating in the blocking direction. This effect is due to the Zener diode having a different pn junction in the center of the diode chip 2 and on the edge 15 . In the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com