Limiting current type oxygen sensor and method of sensing and measuring oxygen concentrations using the same

A limiting current type, oxygen sensor technology, applied in the fields of material electrochemical variables, instruments, electrical digital data processing, etc., can solve the problem that the limit current value cannot be satisfied, and the oxygen concentration cannot be accurately sensed and measured.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

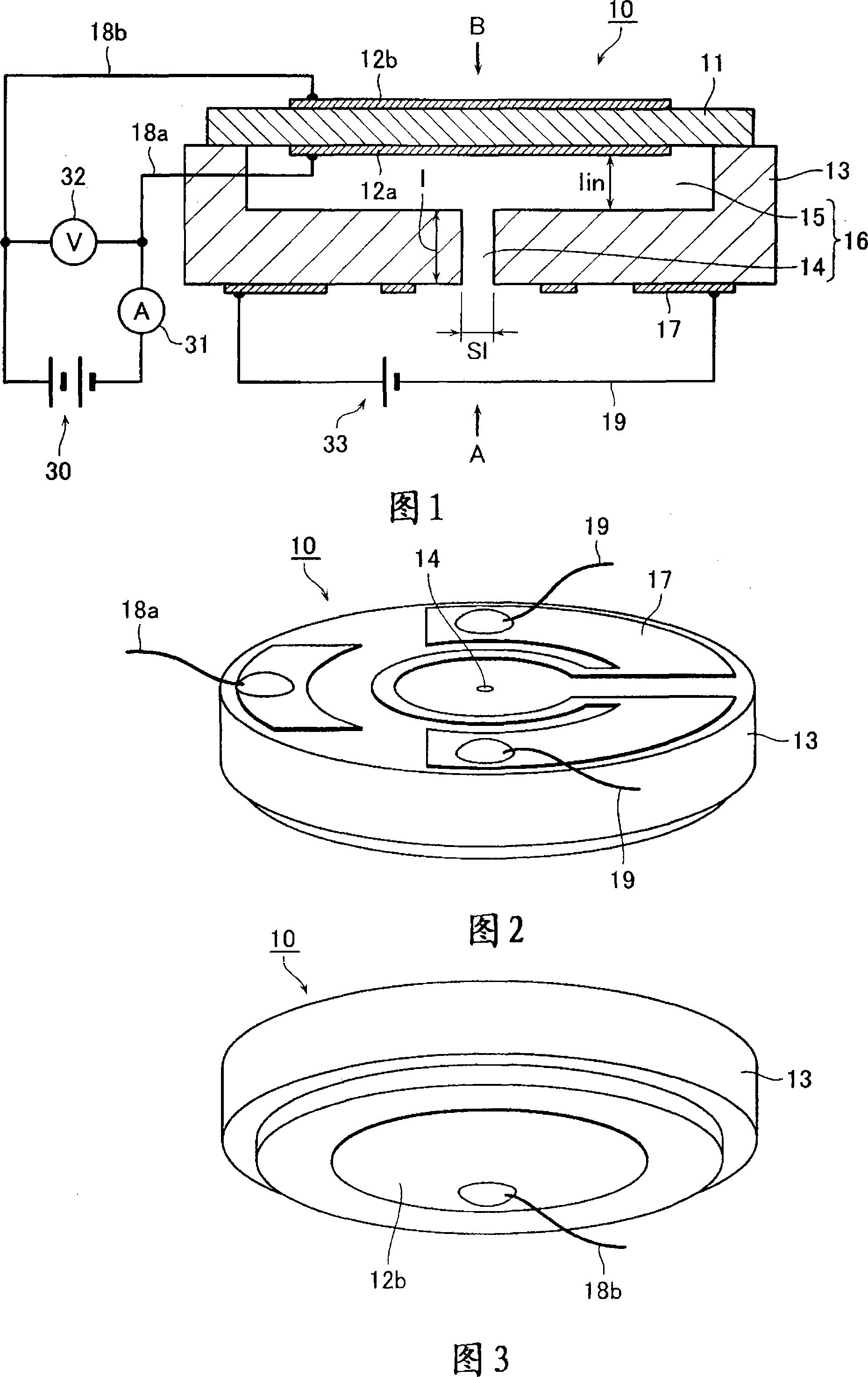

[0039] As shown in FIGS. 1 to 3, a limiting current type oxygen sensor 10 according to a first embodiment of the present invention includes an ionic conductor 11 made of a solid electrolyte, and electrodes 12a, 12b of an electrode pair are arranged to cover one of the electrodes 12a, 12b. A cover 13 for the electrode 12a, and a heater 17 configured to heat the ion conductor 11. The electrodes 12a, 12b are composed of a porous material, which are arranged on the ion conductor 11 for applying an electric field therebetween.

[0040] The ion conductor 11 includes an insulator such as stabilized zirconia exhibiting conductivity at a high temperature of several hundred degrees Celsius due to migration of ions inside. The electrodes 12 a , 12 b may be made of porous platinum (Pt) or silver (Ag), and are formed on both sides of the ion conductor 11 . The limiting current type oxygen sensor 10 of this embodiment is constructed such that the electrode 12a serves as a cathode electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com