Transprinting mechanism and image forming device using the same

A transfer printing and image technology, applied to the electric recording process using the charge pattern, the equipment of the electric recording process using the charge pattern, and the electrography, etc., can solve the problem of delay, non-smooth movement, transfer belt and photosensitive drum Contact separation and other issues, to achieve the effect of precise drive transmission, simple structure, and improved responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

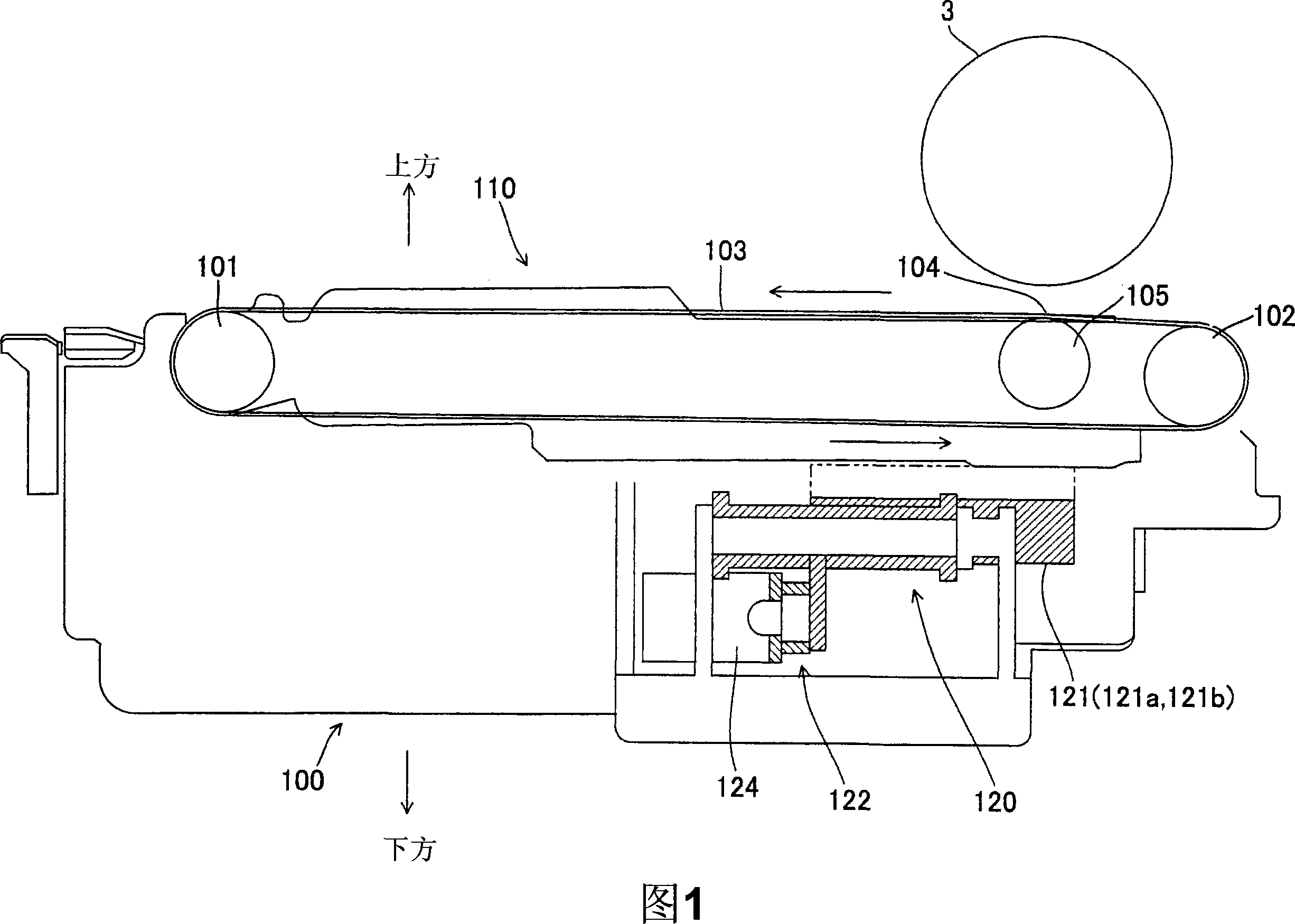

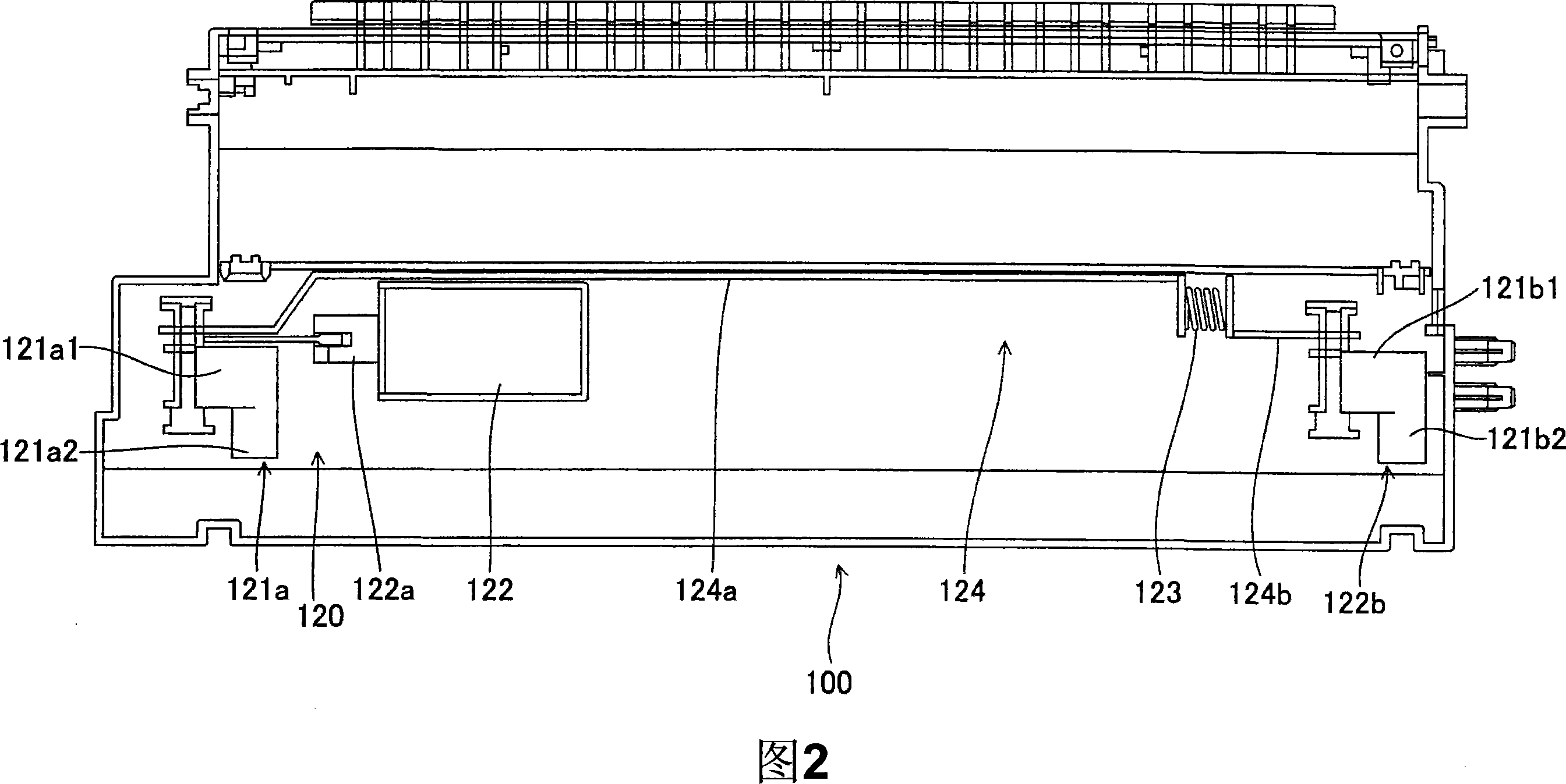

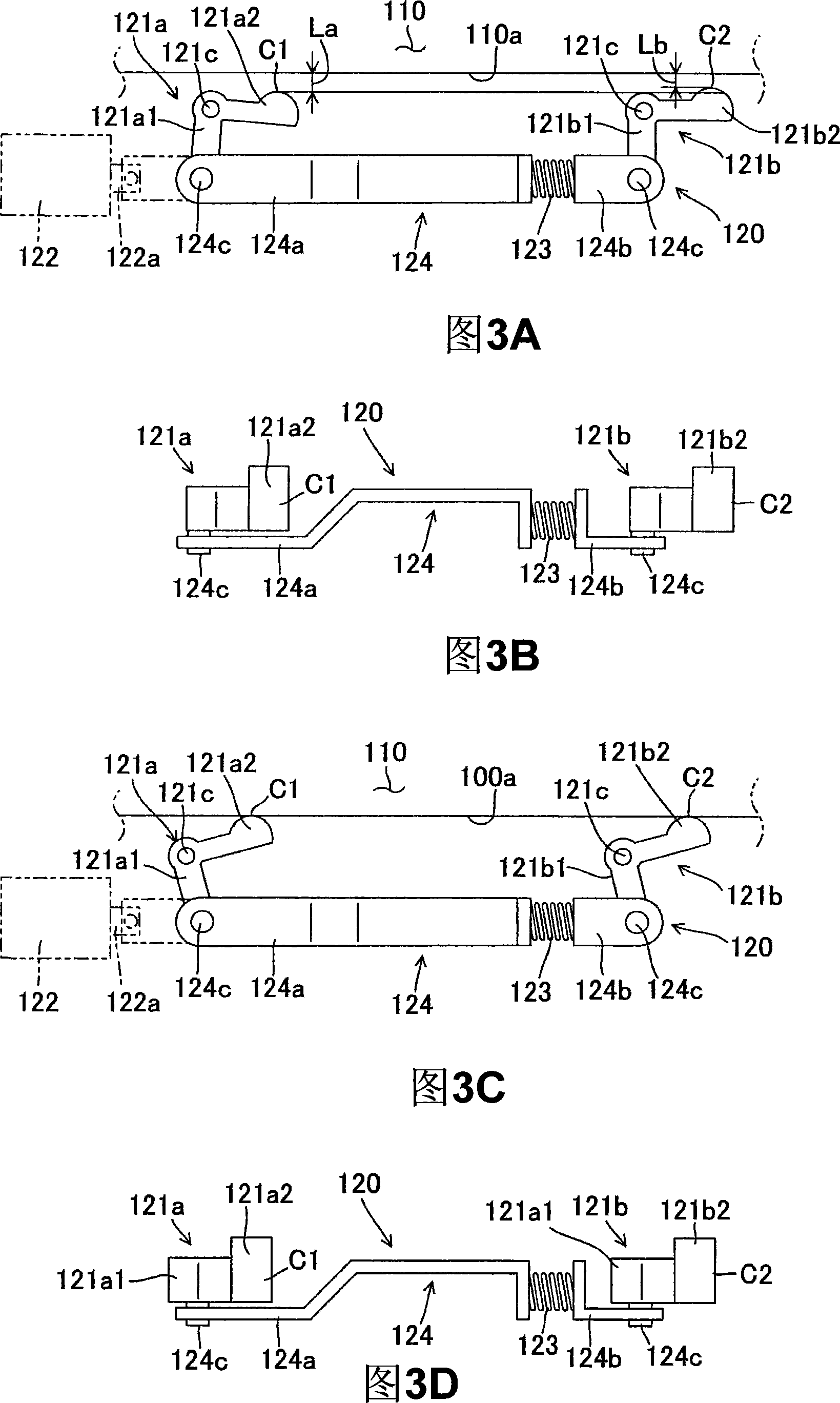

[0048] Hereinafter, an embodiment of the present invention will be described in detail with reference to FIGS. 1 to 6 .

[0049] The transfer mechanism 100 of the present embodiment includes a transfer unit 110 and a belt contact and separation unit 120 ( FIGS. 1 and 2 ). In addition, in FIG. 1 , symbol 3 denotes a photosensitive drum (electrostatic latent image carrier).

[0050] (transfer unit 110)

[0051] The transfer unit 110 includes an endless transfer belt 103 ( FIG. 1 ) that conveys paper (recording medium). The transfer unit 110 transfers the toner image (developer image) developed on the photosensitive drum 3 onto paper conveyed by the transfer belt 103 .

[0052] In addition, the transfer belt 103 may have a structure that does not convey paper. That is, the transfer unit 110 may be configured to directly transfer the toner image developed on the photosensitive drum 3 to the transfer belt 103 .

[0053] The transfer unit 110 is disposed below the photosensitive...

no. 2 approach

[0124] Next, an image forming apparatus 1A equipped with the transfer mechanism 100 of the present invention will be described in detail with reference to the drawings.

[0125] 7 is an explanatory view showing the overall structure of an image forming apparatus employing a transfer mechanism according to a second embodiment of the present invention, and FIG. 8 is a partial detailed view showing the structure of the main body of the image forming apparatus.

[0126] The image forming apparatus 1A of this embodiment is an image forming apparatus that includes an image forming unit 14 , a transfer mechanism 100 , and a fixing unit (fixing mechanism) 6 , and outputs an image according to a print request.

[0127] The image forming unit 14 has a photosensitive drum 3 that forms a developer image (toner) using a developer (toner).

[0128] The transfer mechanism 100 adopts the transfer mechanism of the present invention, and includes the above-mentioned transfer unit 110 and the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com