Organic light-emitting field effect transistor

A field-effect transistor and organic field technology, applied in the field of organic light-emitting field-effect transistor structure, can solve problems such as difficulty in emitting stable light and restricting the development of organic light-emitting field-effect transistors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

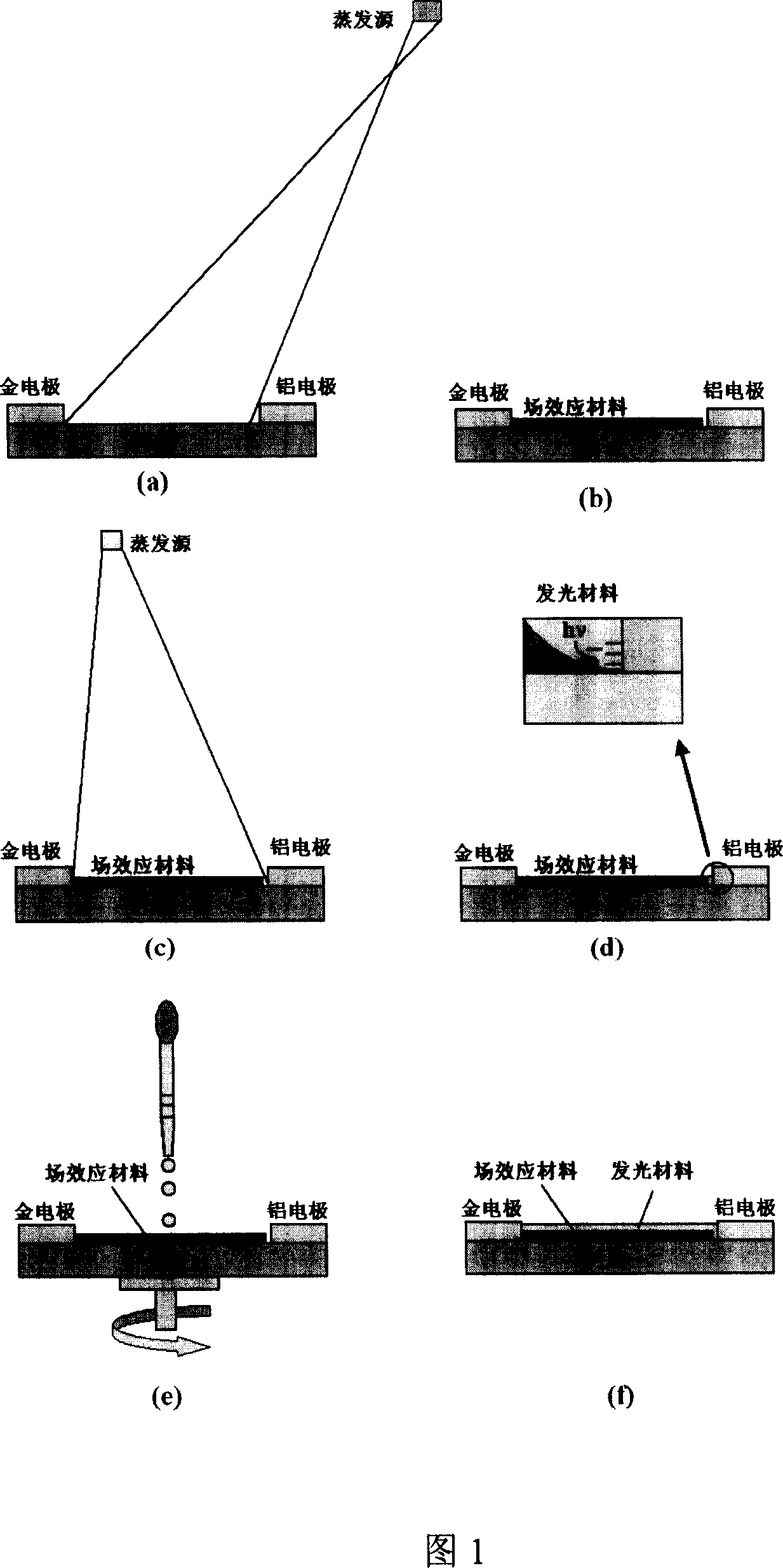

[0054] Fig. 1 shows the preparation flowchart of the non-planar channel field effect transistor of the present invention; Wherein,

[0055] Fig. 1 (a) is vacuum-depositing organic field effect material pentacene on the substrate of the prepared electrode at a certain angle;

[0056] Figure 1(b) is a schematic diagram of the device structure after deposition of pentacene;

[0057] Fig. 1 (c) is the vapor deposition organic electroluminescent material in the opposite direction;

[0058] Figure 1(d) schematic diagram of the prepared organic light-emitting field-effect transistor;

[0059] Fig. 1 (e) is to spin-coat polymer on the substrate that is deposited with pentacene;

[0060] Fig. 1(f) is an organic light-emitting field-effect transistor that emits light from the prepared polymer.

[0061] A field effect transistor of the present invention sequentially comprises a substrate, an insulating layer, a gate electrode, a source-drain electrode, and an organic layer. The subst...

Embodiment 2

[0071] According to the preparation of Example 1, the difference is that the thickness of pentacene is 100 nm and TPA-PPV is spin-coated at a speed of 2000 rpm as the organic electroluminescence material. Organic light-emitting field-effect transistors that emit light from polymers were fabricated.

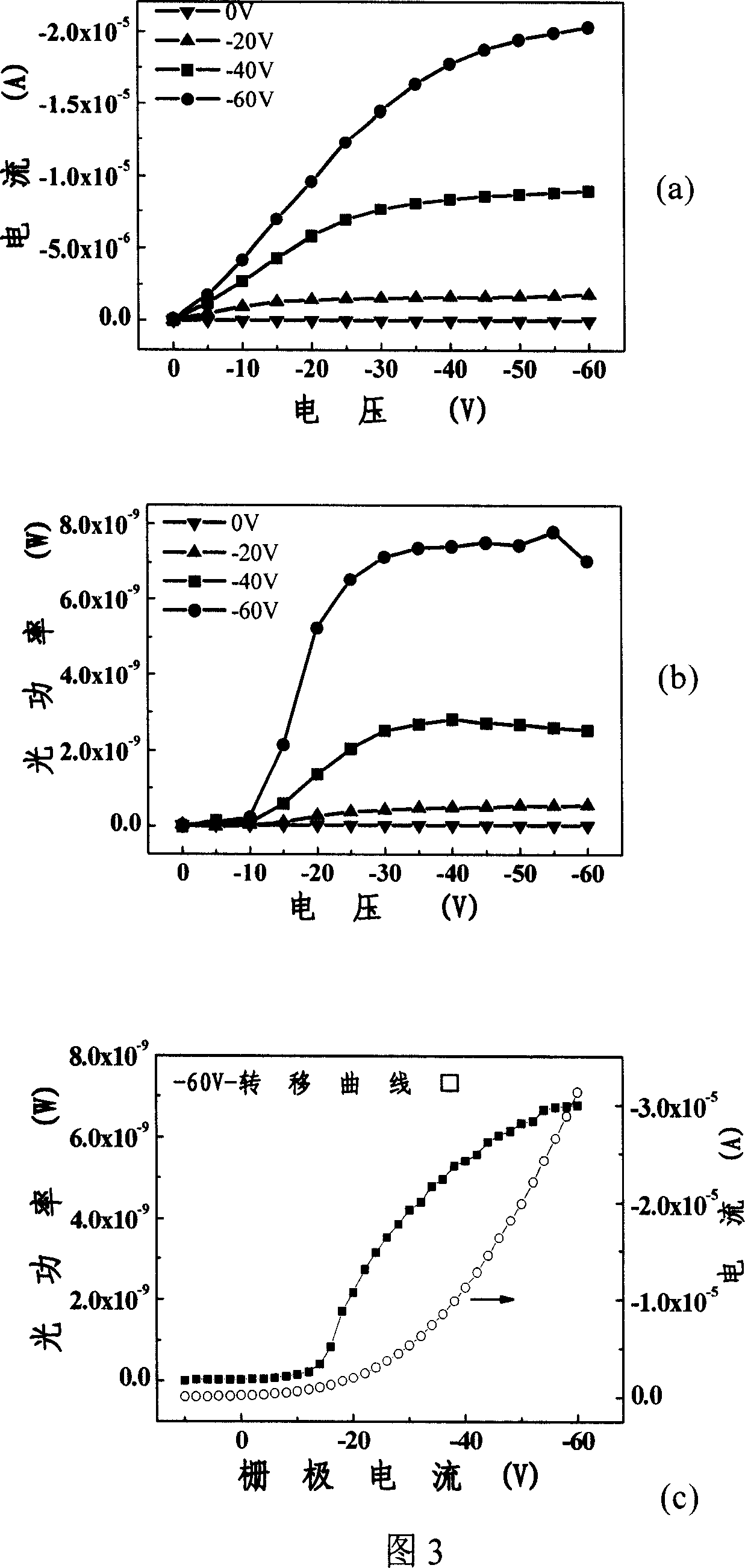

[0072] Fig. 5 is the optical power output curve of the organic light emitting field effect transistor with the channel length of 6 microns, the source and drain electrodes being gold and aluminum electrodes, and the organic semiconductor being pentacene and TPA-PPV in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com