A glass-ceramic with high-efficiency white light emission and its preparation method

A technology of glass ceramics and white light, applied in the field of solid luminescent materials, can solve the problems of unsatisfactory high-performance devices, insufficient red light emission intensity, low color rendering index, etc., to avoid easy aging, stable physical and chemical properties, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

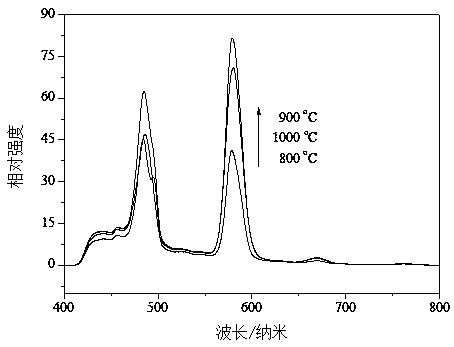

Embodiment 1

[0032] (1) Accurately weigh the raw materials according to the proportion.

[0033] According to SiO 2 :91%, Al 2 o 3 :3%, SrO:6%, Dy 3+ A total of 11 g of raw materials were weighed with a doping amount of 2%. The glass composition and raw material quality are shown in Table 1.

[0034] (2) First, the solution containing TEOS, ethanol, and deionized water was continuously stirred at room temperature for 1 hour, and the molar ratio of TEOS:ethanol:H 2 O=1:1:3. Second, the Sr(NO 3 ) 2 Soluble in deionized water.

[0035] (3) Al 2 o 3 、Dy 2 o 3 dilute HNO 3 Dissolve, heat and stir to remove excess nitric acid in the solution, in which dilute HNO 3 According to volume ratio water:HNO 3 =3:1 preparation.

[0036] (4) Mix the solutions of step (2) and step (3) to control the molar ratio H in the final solution 2 O:TEOS=15:1, and the resulting mixture was continuously stirred for 2 hours. Then the solution was added to a plastic petri dish and left to stand at room...

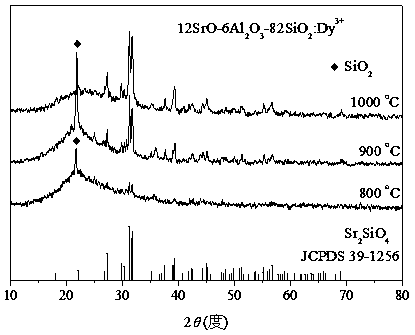

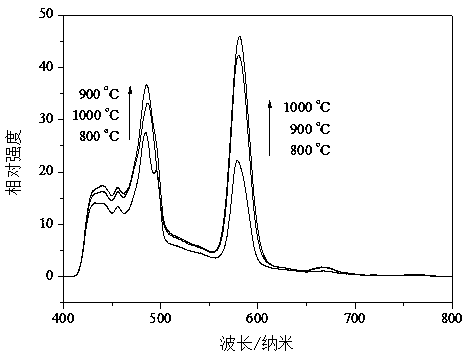

Embodiment 2

[0041] (1) Accurately weigh the raw materials according to the proportion.

[0042] According to SiO 2 :82%, Al 2 o 3 :6%, SrO:12%, Dy 3+ Raw materials were weighed at a ratio of 2% doping. The quality of each raw material is shown in Table 2.

[0043] (2) First, the solution containing TEOS, ethanol, and deionized water was continuously stirred at room temperature for 1 hour, and the molar ratio of TEOS:ethanol:H 2O=1:1:5. Second, the Sr(NO 3 ) 2 Soluble in deionized water.

[0044] (3) Al 2 o 3 、Dy 2 o 3 dilute HNO 3 Dissolve, heat and stir to remove excess nitric acid in the solution, in which dilute HNO 3 According to volume ratio water:HNO 3 =3:1 preparation.

[0045] (4) Mix the solutions of step (2) and step (3) to control the molar ratio H in the final solution 2 O:TEOS=15:1, and the resulting mixture was continuously stirred for 2 hours. Then the solution was added to a plastic petri dish and left to stand at room temperature for 30 days to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com