Luminous glass ceramic used for LED white-light illumination and preparation method thereof

A technology of luminescent glass and ceramics, which is applied in the direction of optical elements, lighting and heating equipment, and components of lighting devices used to change the spectral characteristics of emitted light. Problems such as poor temperature stability, to achieve the effect of improving luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] By composition 50SiO 2 -20Al 2 o 3 -10ZnF 2 -20CeF 3 -2DyF 3 -2EuF 3 Weigh SiO 2 , Al 2 o 3 , ZnF 2 , CeF 3 , DyF 3 and EuF 3 , and mix the above raw materials well, put them into a graphite-corundum double-layer crucible, and put them into a melting furnace that has been heated to 1350 ° C. After the melting material is kept at 1350 ° C for 30 minutes, it is quickly taken out from the melting furnace Crucible, the melt in the crucible is quickly poured into a copper mold to obtain a glass sample. According to the DTA curve of the glass, the glass was heat-treated at 630° C. between the first crystallization peak temperature and the glass transition temperature for 2 hours to obtain glass ceramics. XRD analysis shows that CeF is distributed in the glass ceramics 3 nanocrystalline phase.

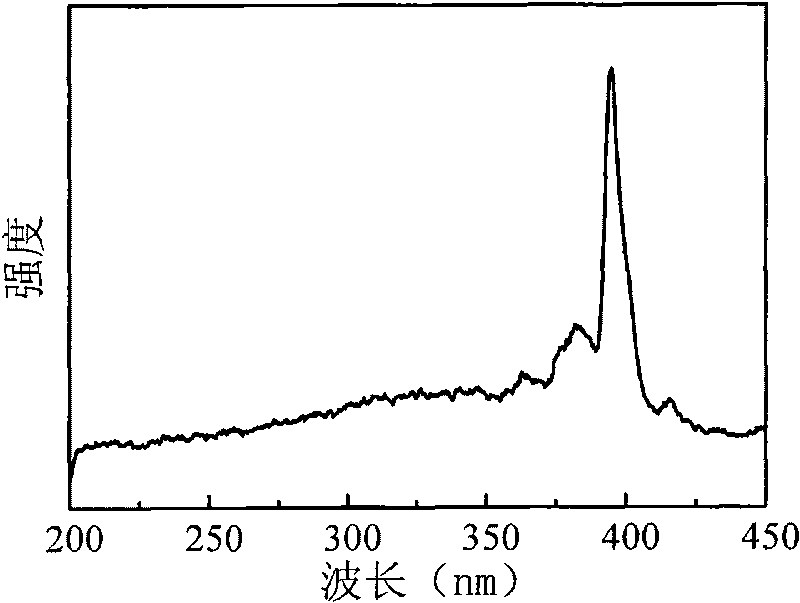

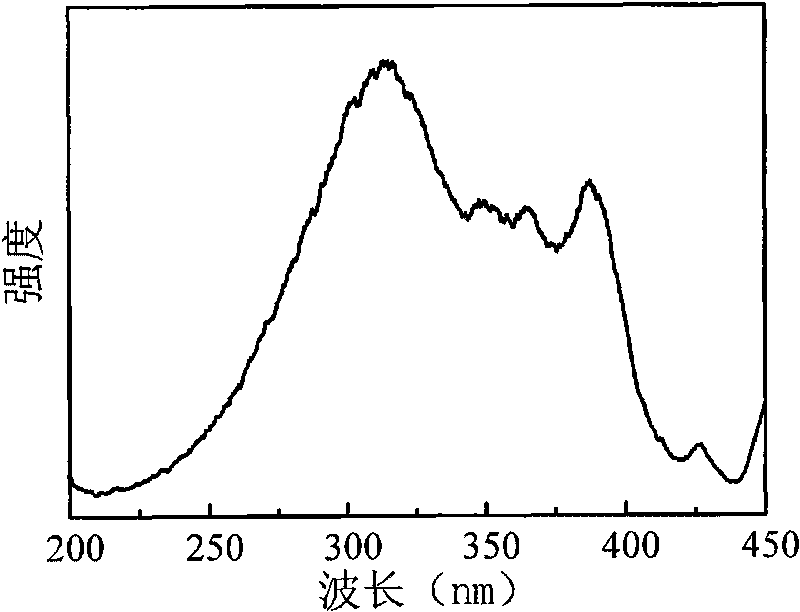

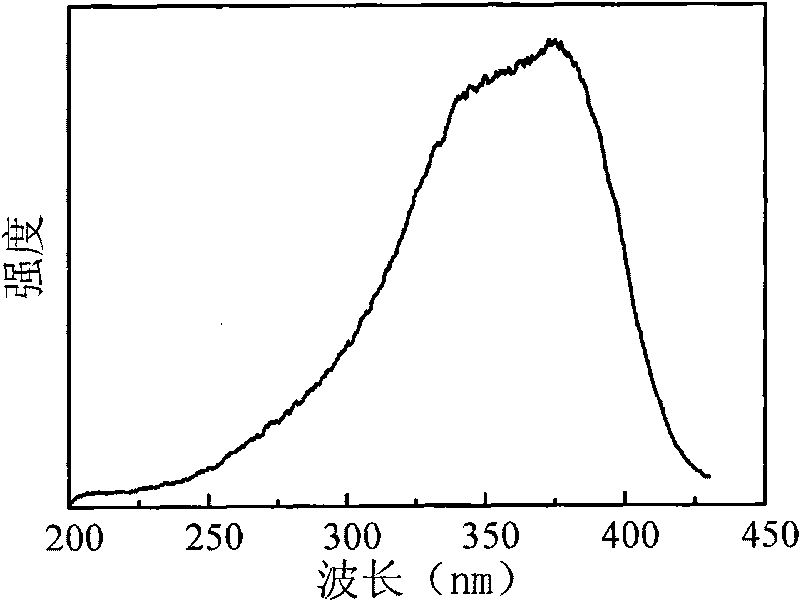

[0031] The glass-ceramics that this example makes is under 615nm monitoring, 576nm monitoring and 440nm monitoring the excitation spectrum, as respectively figure 1 , ...

Embodiment 2

[0033] According to the composition of 51SiO 2 -20Al 2 o 3 -15Na 2 O-12CeF 3 -1DyF 3 -1EuF 3 Weigh SiO 2 , Al 2 o 3 , Na 2 CO 3 , CeF 3 , DyF 3 and EuF 3, and the above raw materials are fully mixed, placed in a graphite-corundum double-layer crucible, and put into a melting furnace that has been heated to 1500 ° C to melt the raw materials into a liquid state. After the melting material is kept at 1500 ° C for 45 minutes, The crucible is quickly taken out of the furnace, and the molten material in the crucible is quickly poured into a copper mold to obtain glass. The obtained glass was subjected to differential thermal analysis, and the first crystallization peak temperature was 710°C, and the glass transition temperature was 610°C. The glass was heat-treated at 710°C for 0.5 hours to obtain glass ceramics. XRD analysis shows that the CeOF nanocrystalline phase is distributed in the glass ceramics. Spectral tests show that the glass ceramic can realize white li...

Embodiment 3

[0035] By composition 60SiO 2 -20ZnF 2 -15CeF 3 -2DyF 3 -3EuF 3 Weigh SiO 2 , Al 2 o 3 , CaF 2 , CeF 3 and DyF 3 , and add 0.5mol% As to the above raw material 2 o 5 and 1mol% LiF, after fully mixed, put it into a graphite-corundum double-layer crucible, put it into a melting furnace that has been heated to 1400°C, and melt the raw material into a liquid state. After the melt is kept at 1400°C for 1 hour, from The crucible is quickly taken out from the melting furnace, and the melt in the crucible is quickly poured into a copper mold to obtain a glass sample. According to the DTA curve of the glass, the first crystallization peak temperature is 660°C, and the glass transition temperature is 580°C. The glass is heat-treated at 630°C for 2 hours to obtain glass ceramics. XRD analysis shows that the CeF3 nanocrystalline phase is distributed in the glass ceramics. Spectral tests show that the glass ceramic can realize white light emission with a chromaticity close to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com