Application of polyurethane foam slit filling agent in repairing damp ancientry tomb chamber fresco empty drum

A technology of polyurethane foam and caulking agent, which is applied in the direction of preservation of paintings, decorative arts, building components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The method of using polyurethane foam caulking agent to repair the hollow drum of damp ancient tomb murals at a relative humidity of 70% is as follows:

[0021] (1) Use a scalpel to cut a circular hole with a diameter of 5 mm in the damaged crack or secondary part of the mural, use an endoscope to observe the internal conditions between the mural ground and the wall, and use a vacuum cleaner to vacuum the mural hollow. Clean up debris such as sand, broken ground, and debris.

[0022] (2) Preparation of reinforcing agent

[0023] Add Remmers300 and absolute ethanol at a volume ratio of 1:4 into a beaker, stir and mix evenly to prepare a reinforcing agent. Remmers300 is produced by Remmers, Germany.

[0024] (3) Use a 100mL syringe to drop the reinforcing agent to reinforce the floor and wall inside the mural hollow, so that the strength of the mural layer and the loose parts of the wall will increase.

[0025] (4) After the reinforcing agent is cured, use a sponge to w...

Embodiment 2

[0029] The method of using polyurethane foam caulking agent to repair the hollow drum of damp ancient tomb murals at a relative humidity of 55% is as follows:

[0030] In step (5), a polyurethane foam caulking agent spray gun is inserted into the opening of the mural, and the polyurethane foam caulking agent is injected into the hollow drum, and the filling amount is 40% of the inner volume of the mural hollow drum. Other steps are the same as in Example 1.

Embodiment 3

[0032] The method of using polyurethane foam caulking agent to repair the hollow drums of damp ancient tomb murals at a relative humidity of 100% is as follows:

[0033] In step (5), a polyurethane foam caulking agent spray gun is inserted into the opening of the mural, and the polyurethane foam caulking agent is injected into the hollow drum, and the filling amount is 50% of the inner volume of the mural hollow drum. Other steps are the same as in Example 1.

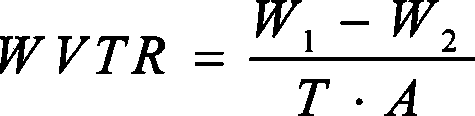

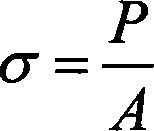

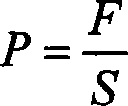

[0034] In order to determine the application of polyurethane foam caulking agent in repairing the hollow drums of damp ancient tomb murals, the inventors used polyurethane foam caulking agents to carry out a large number of laboratory tests and trials for repairing the hollow drums of wet ancient tomb murals. The various test conditions are as follows:

[0035] Test instruments: LRO16A aging test box, produced by Chongqing Yinhe Test Instrument Co., Ltd.; TD-6001B tensile testing machine, produced by Jiangdu Tengda Test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com