Method for preparing amorphous cellulose aerogel with ionic liquid

A technology of cellulose airgel and ionic liquid, which is applied in the production of bulk chemicals, etc., can solve the problems of inorganic aerogels being out of shape and poor toughness, and achieve the effects of improving use value, good mechanical strength, and broadening applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

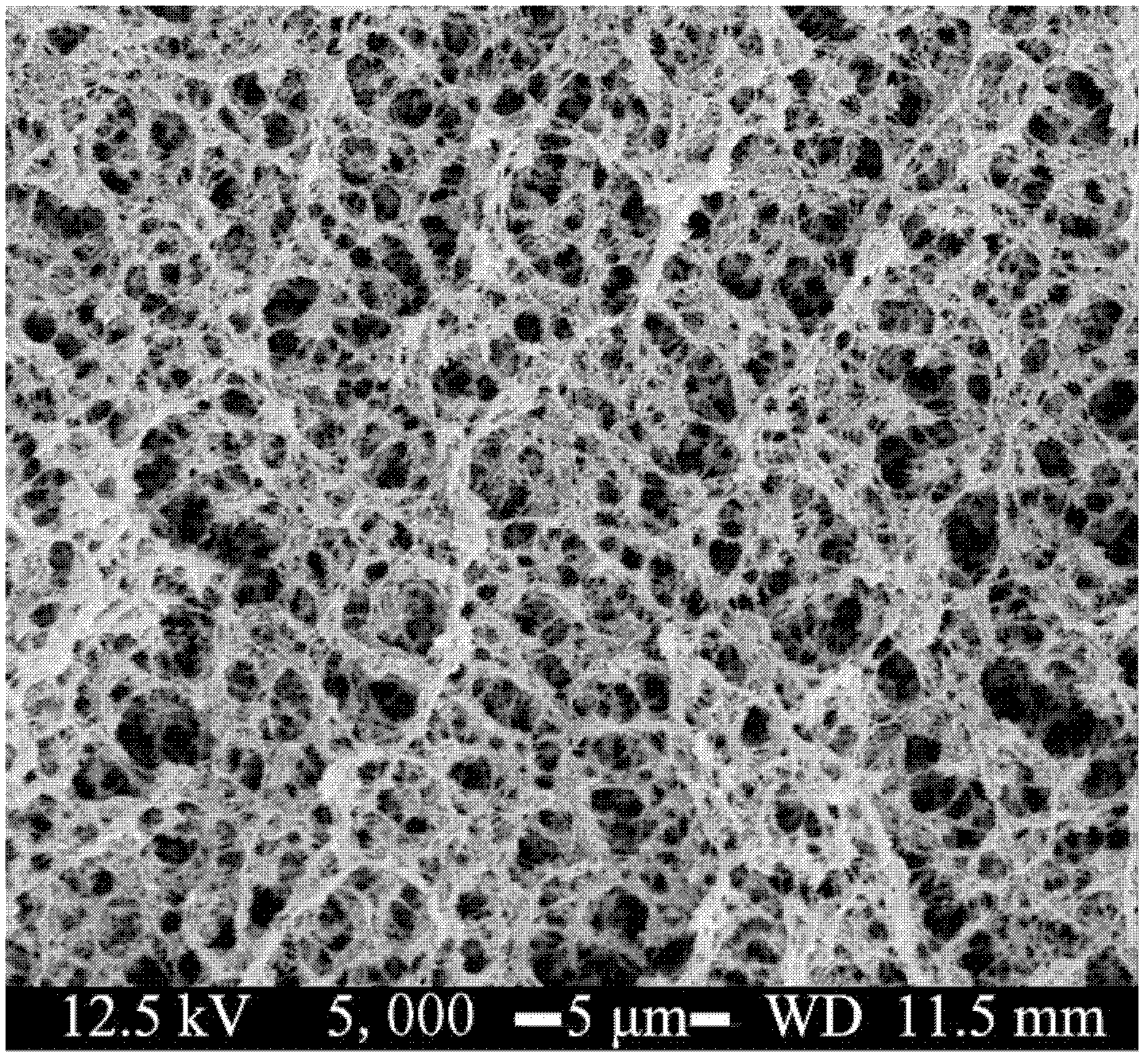

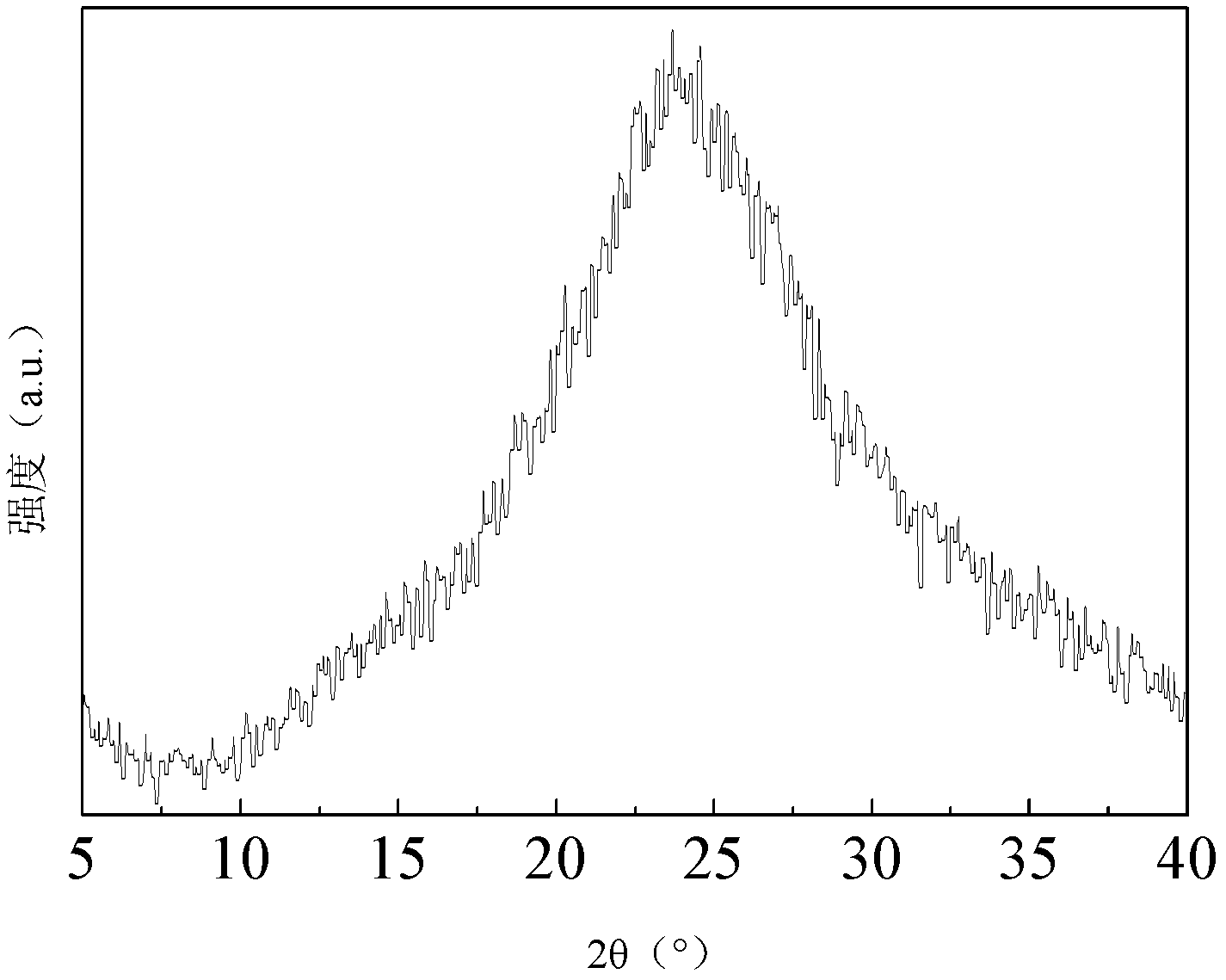

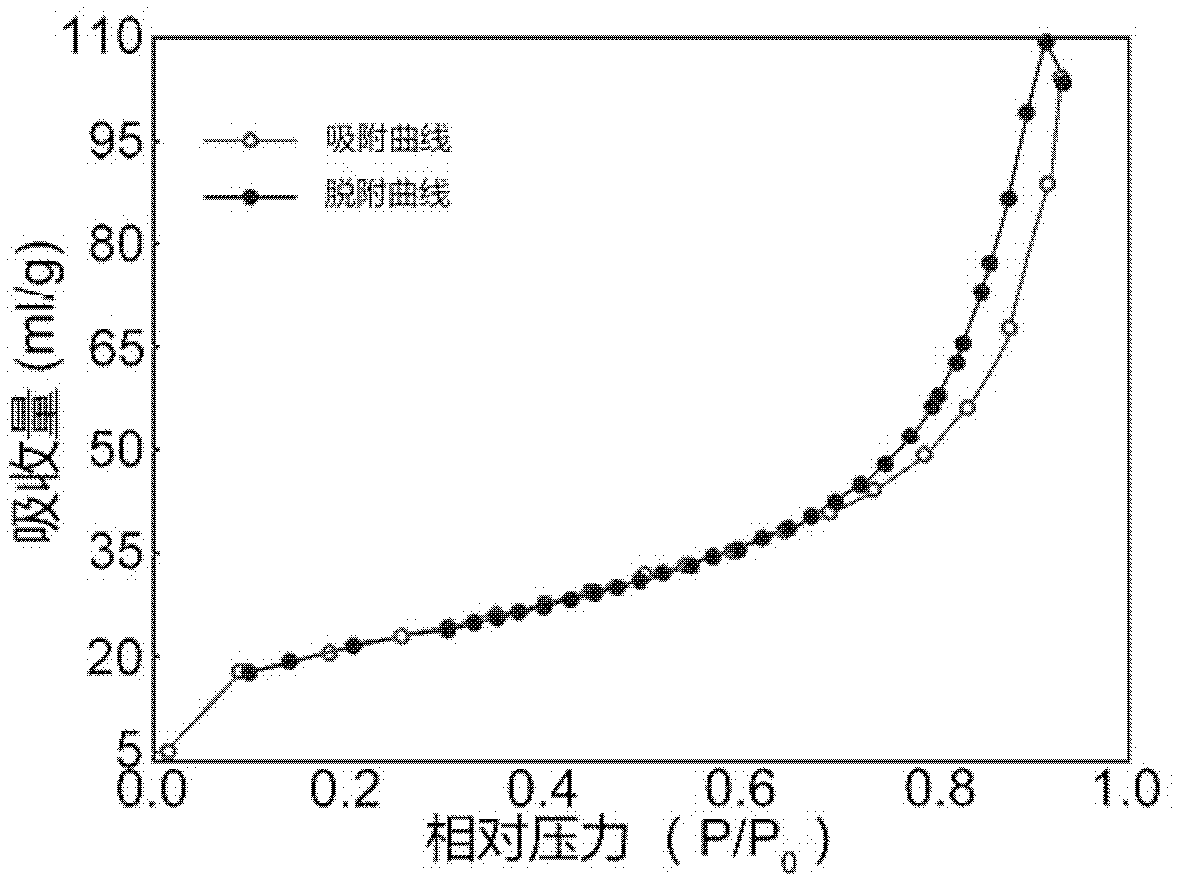

[0013] Specific embodiment one: utilize ionic liquid to prepare the method for amorphous airgel in this embodiment mode and carry out according to the following steps:

[0014] Step 1, drying the natural cellulose in vacuum;

[0015] Step 2, vacuum-dry the ionic liquid, then heat it to 80-150° C. with an oil bath, add the vacuum-dried natural cellulose, the vacuum-dried natural cellulose accounts for the vacuum-dried natural cellulose and the vacuum-dried natural cellulose 0.5% to 20% of the total mass of the liquid, stirred until a uniform transparent solution, the ionic liquid is chlorinated salts of quaternary ammoniums, dialkylimidazoles, N-alkylpyridines, carboxylates of quaternary ammoniums and Dialkylimidazoles, N-alkylpyridines, alkyl phosphate salts of quaternary ammoniums (such as 1-allyl-3-methylimidazolium chloride ionic liquid or 1-butyl-3-methylimidazolium Chloride salt ionic liquid), then cooled to room temperature, poured into the mold, and sealed;

[0016] S...

specific Embodiment approach 2

[0020] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the natural cellulose in Step 1 comes from cotton, wood, bamboo, hemp, bagasse, straw or coconut shell. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that: in step 2, the oil bath is heated to 100-130°C. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com