Molten iron pot narrow gap gas-blowing slag-removing device and operation technique thereof

A technology of molten iron tanks and narrow slits, which is applied in the field of metallurgy, can solve the problems of low spray gun life and low slag removal efficiency, and achieve the effect of low labor intensity, high slag removal rate and clean slag removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

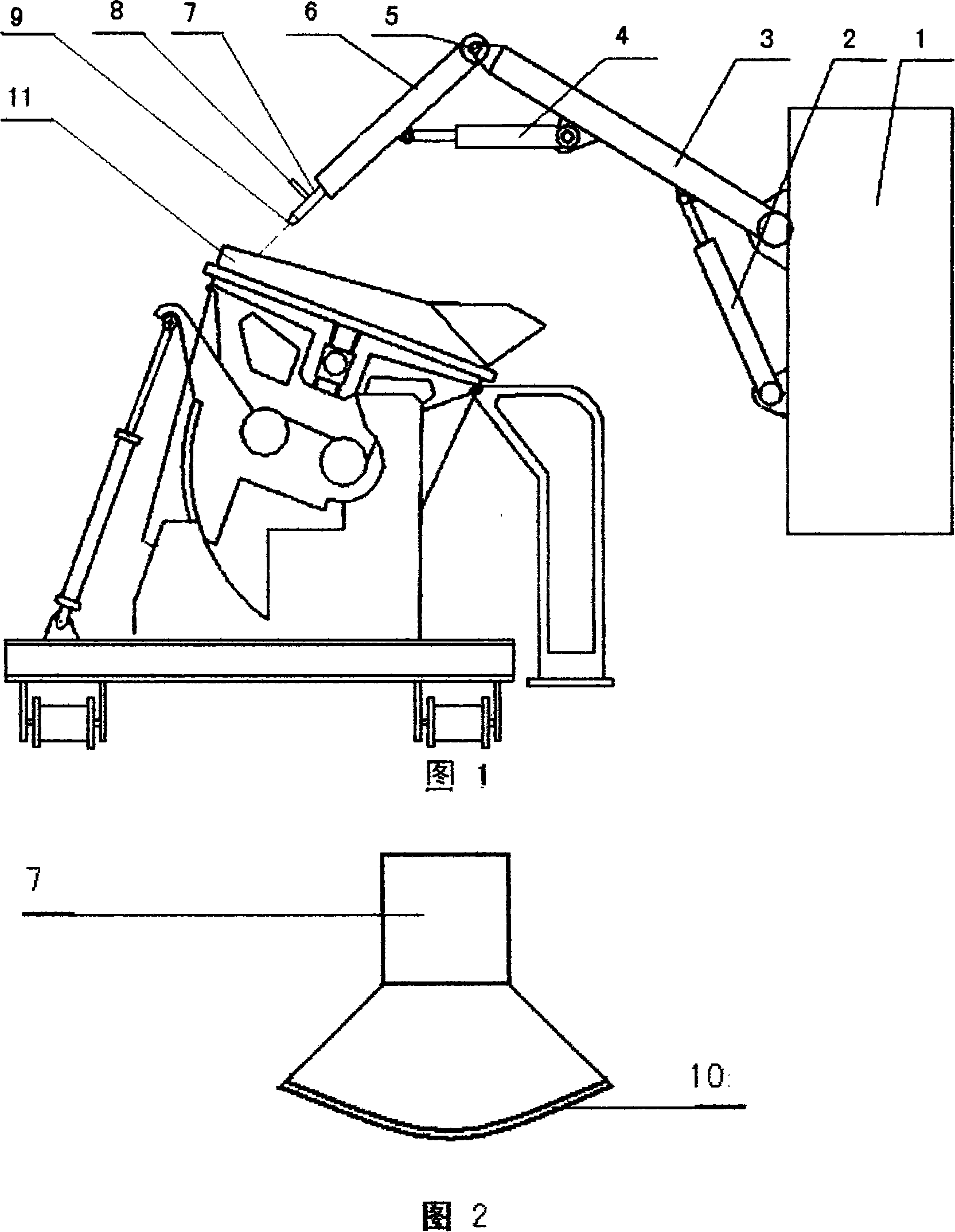

[0011] With reference to the accompanying drawings, the device of the present invention includes a molten iron tank 11, which is characterized by a mechanical arm composed of a first hydraulic cylinder 2 and a second hydraulic cylinder 4, a first horn 3, a second horn 6 and a movable joint 5 , the mechanical arm is provided with a blowpipe 7, and the blowpipe 7 is provided with a gas connecting pipe 8 and a nozzle 9, and the said nozzle 9 is a slit-shaped nozzle 10, which is formed by the first hydraulic cylinder 2 and the second hydraulic cylinder 4, the first hydraulic cylinder The mechanical arm formed by the horn 3 , the second horn 6 and the movable joint 5 is arranged on the trolley 1 .

[0012] The operating process adopted by the molten iron pouring narrow slit air blowing slag removal device of the present invention is:

[0013] A. First connect the gas connecting pipe 8 to the nitrogen pipe or air compressor;

[0014] B. Tilt the molten iron tank 11 by 5° to 45° at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com