Centrifugal compressor ammonia compressor rapid vibration-prevention method and device

An ammonia compressor and centrifugal technology, applied in the field of anti-turbulence, can solve the problems of damage to the compressor rotor, insufficient volatilization of liquid ammonia, endangering equipment safety, etc., so as to prevent turbulence, stabilize the gas source, and reduce the cooling power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

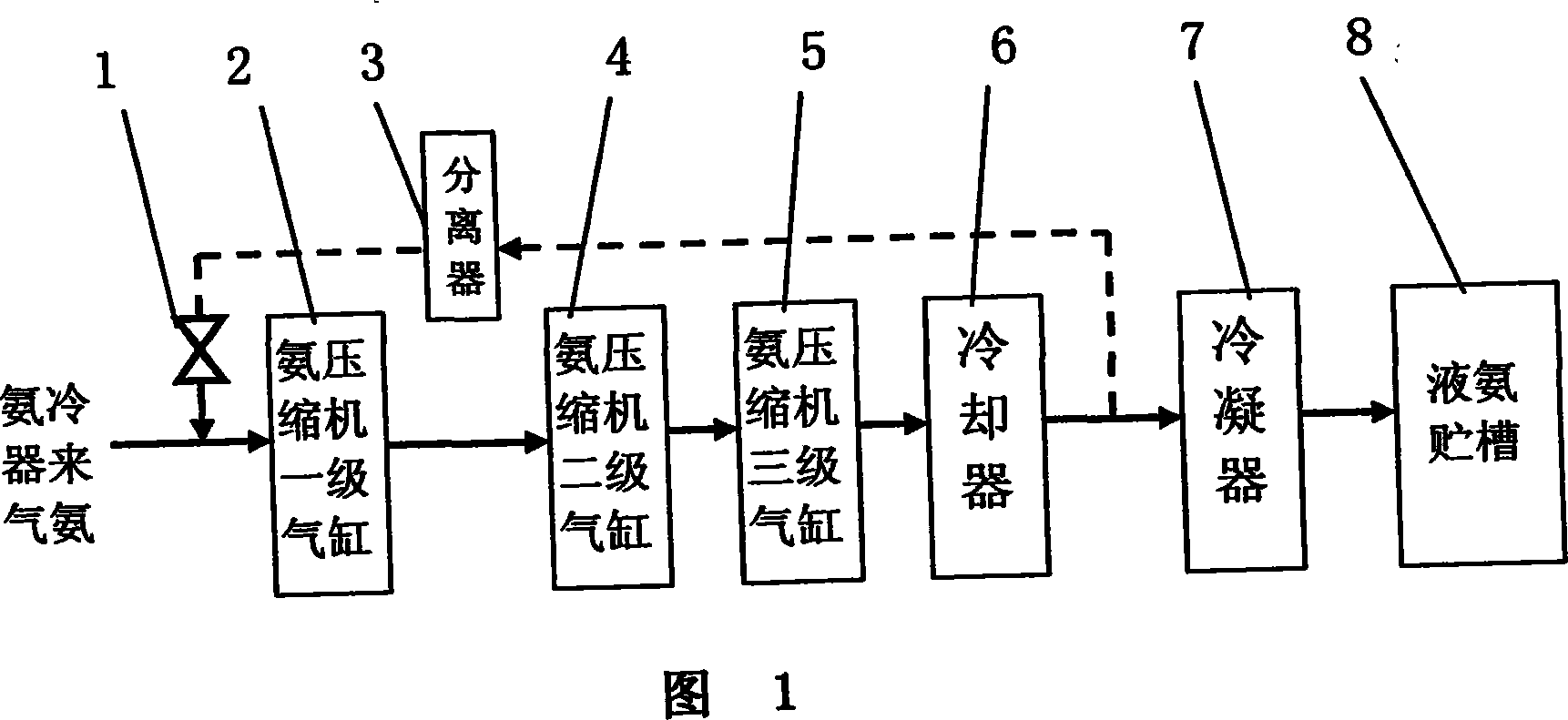

[0019] The outstanding feature of the present invention is that gaseous ammonia is used instead of liquid ammonia as the supplementary source of the inlet flow of the centrifugal ammonia compressor to prevent turbulence. The specific technical means are: lead a bypass pipeline from the outlet pipeline of the ammonia compressor to communicate with the inlet of the ammonia compressor, and feed the compressed ammonia gas back to the inlet of the ammonia compressor.

[0020] The bypass pipeline can be drawn from the outlet 2 of the first stage of the ammonia compressor, or from the outlet of the second stage 4 or the third stage 5 of the ammonia compressor, but it is better to lead from the outlet of the third stage cooler 5, as shown in Figure 1. In this way, gas ammonia can be provided to the inlet of the ammonia compressor, and the liquefied ammonia in the liquid ammonia storage tank 8 can not be used as the flow replenishment source of the inlet of the ammonia compressor, so as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com