Eutectic powder additive for ceramics production or weld and method for preparing the same

A technology of eutectic powder and additives, applied in the field of producing ceramics or eutectic powder additives for ceramic welding and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

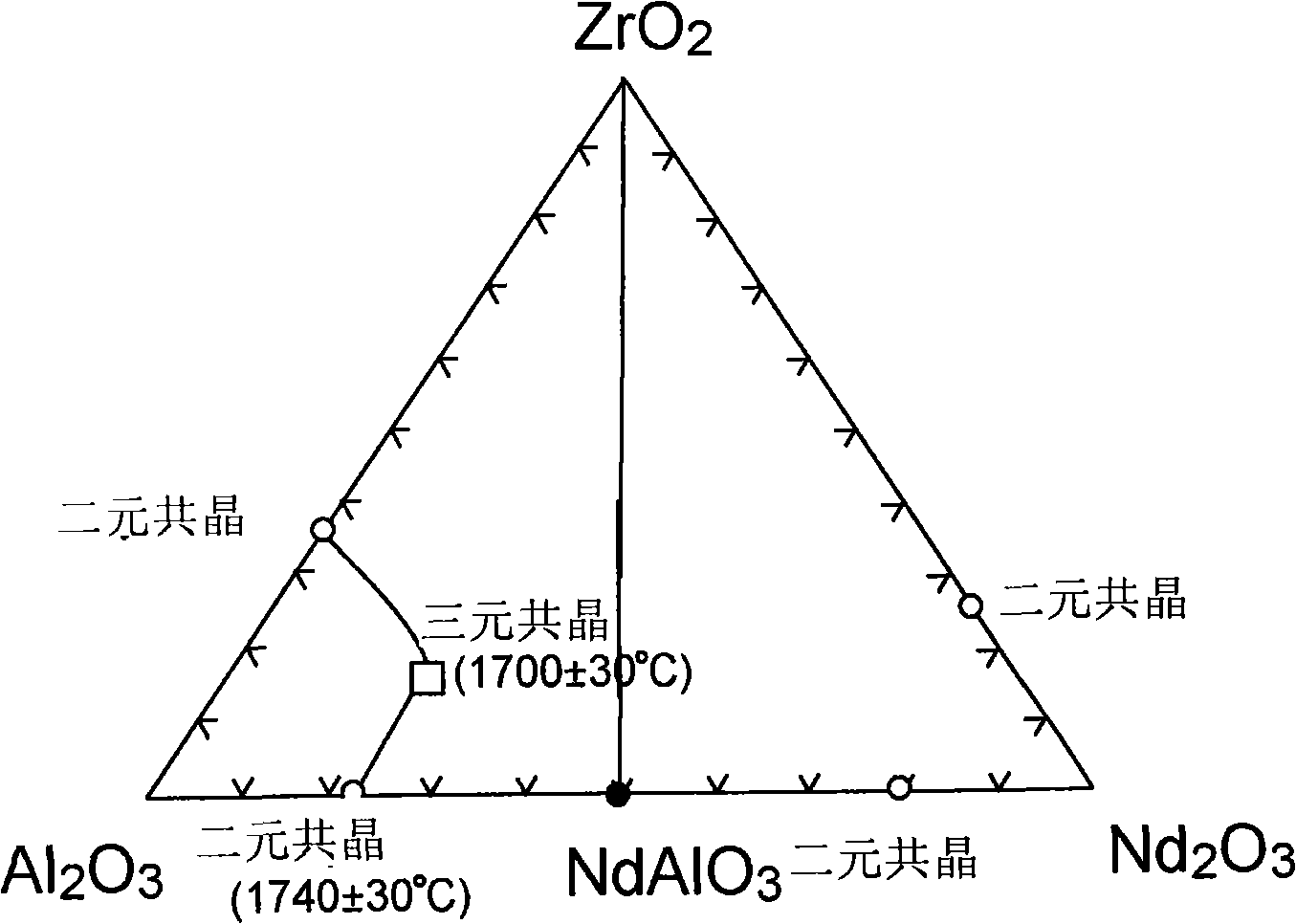

[0164] Take Al 2 o 3 / NdAlO 3 / ZrO 2 Examples of the preparation of eutectic powder additives, in image 3 In, Al 2 o 3 / NdAlO 3 / ZrO 2 The preparation formula of the eutectic composite powder is 55-65mol% Al 2 o 3 , 15-25mol% Nd 2 o 3 , 15-30mol% ZrO 2 , melting temperature is 1700±30℃, with Nd 2 o 3 , ZrO 2 and Al 2 o 3 Powder as raw material, according to 55-65mol% Al 2 o 3 , 15-25mol% Nd 2 o 3 , 15-30mol% ZrO 2 , Proportional mixing, after stirring evenly, the eutectic powder is obtained. The eutectic powder is pressed into a cylindrical body with a diameter of 5-20 mm under a pressure of 10-20 MPa, and then melted in 20 cmHg of Ar gas in a small DC electric arc furnace with a rated voltage of 100 V and a current of 600 A. system. The phase of the prepared eutectic composite ceramics is Al 2 o 3 , NdAlO 3 and ZrO 2 , the microstructure is columnar structure, see Figure 7 (a), where the small white round particles are NdAlO 3 , the white triang...

Embodiment 2

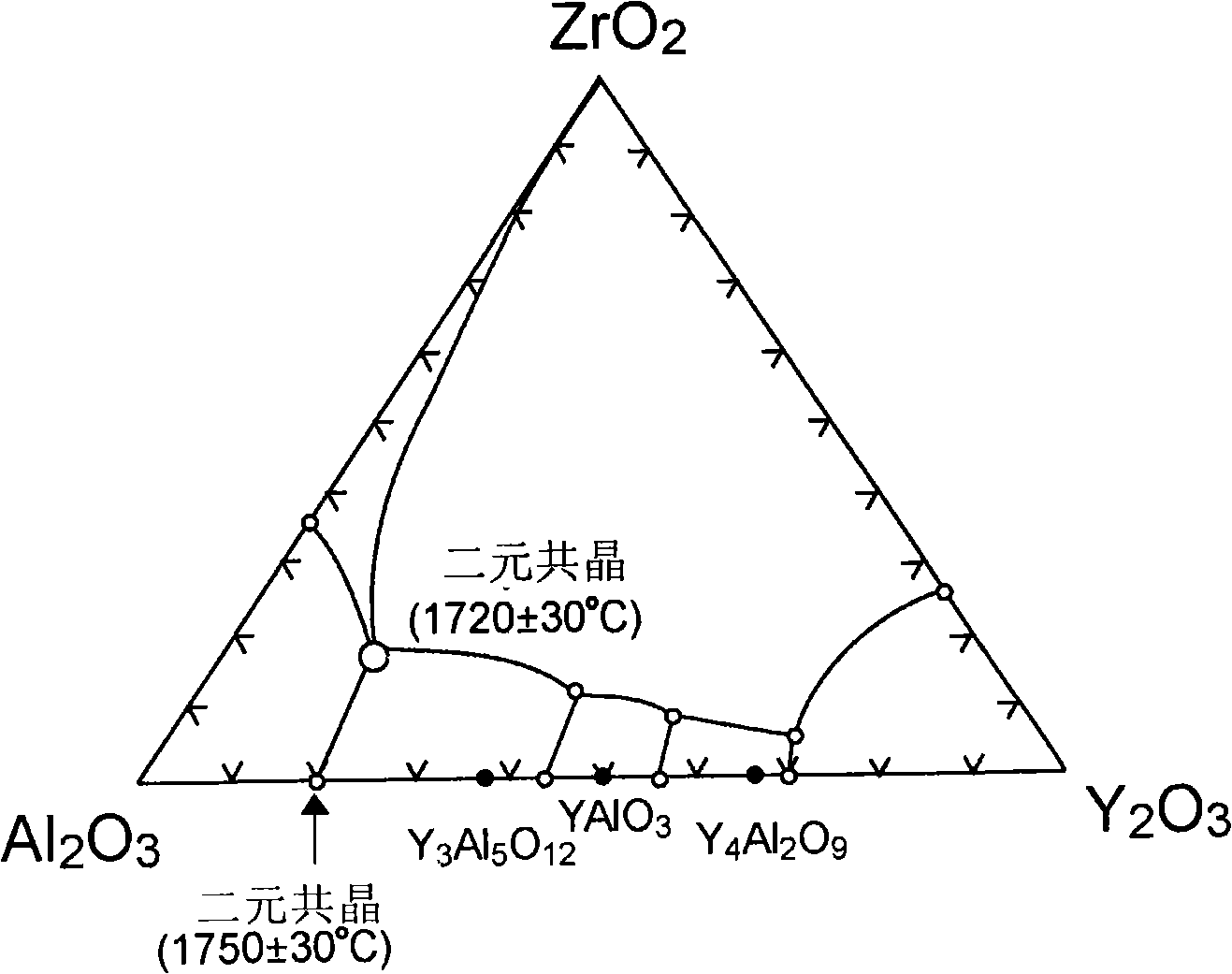

[0166] Take Al 2 o 3 / Y 3 Al 5 o 12 / ZrO 2 Eutectic Powder Additives as Sintering Aids to Reduce Si 3 N 4 And the sintering temperature of SiC ceramics as an example. exist Figure 4 Al 2 o 3 / Y 3 Al 5 o 12 / ZrO 2 The preparation formula of eutectic composite ceramic powder is 60-70mol% Al 2 o 3 , 10-20mol% Y 2 o 3 , 15-25mol% ZrO 2 . to Y 2 o 3 , ZrO 2 and Al 2 o 3 Powder is raw material, and the eutectic composite ceramic phase that makes by the same method of embodiment 1 is Al 2 o 3 , Y 3 Al 5 o 12 and ZrO 2 , the microstructure is a layered structure, and the layered particles Y 3 Al 5 o 12 , Al 2 o 3 and ZrO 2 The thicknesses are 600nm, 200nm and 600nm respectively, see Figure 7 (b). Al prepared above 2 o 3 / Y 3 Al 5 o 12 / ZrO 2 The eutectic composite ceramics are crushed into a eutectic composite powder with a particle size of 0.5-50 μm in a mortar.

[0167] exist Figure 4 It can be seen that Al 2 o 3 / Y 3 Al 5 o 12 / Z...

Embodiment 3

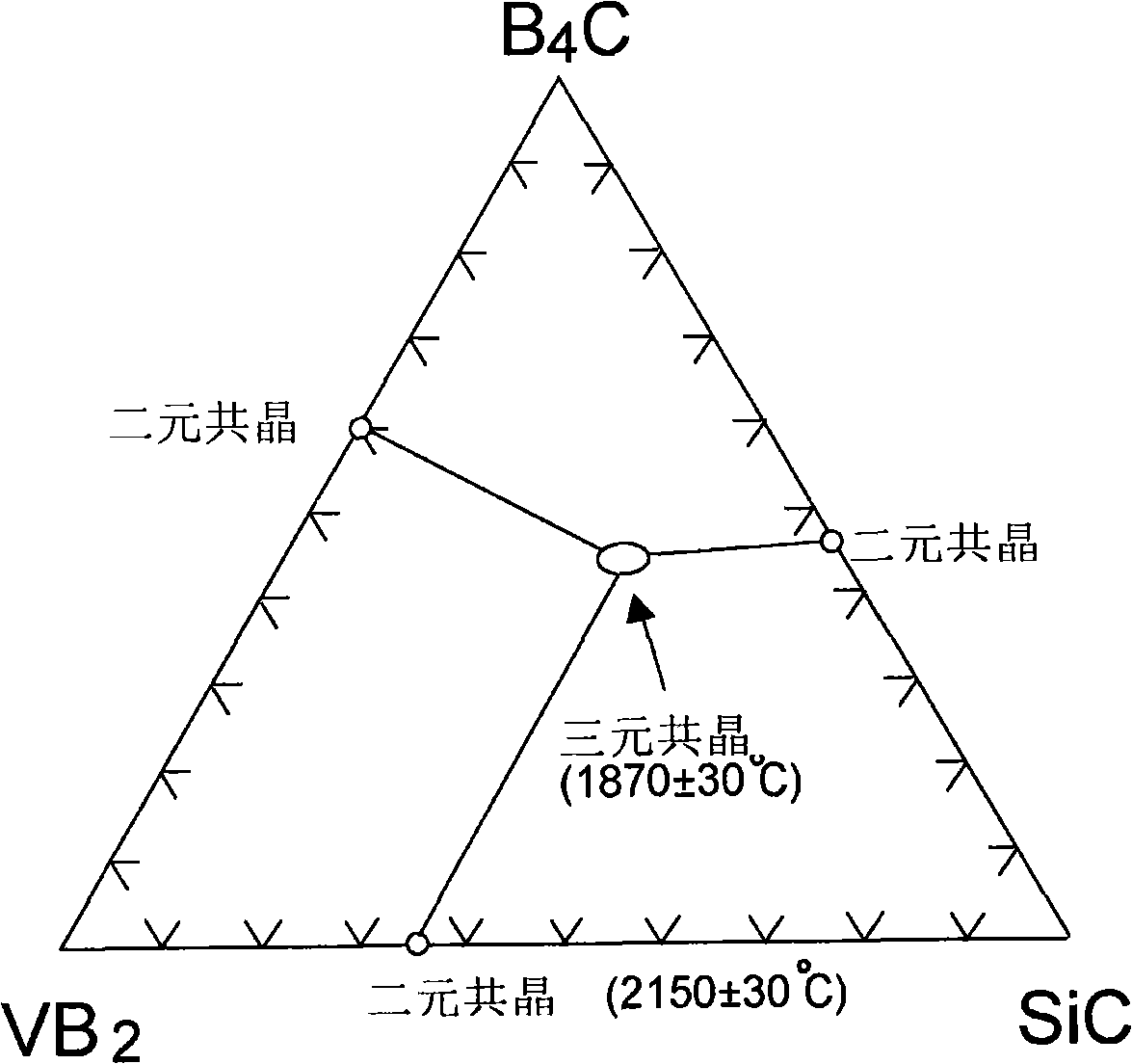

[0175] Take VN / SiC / B 4 C eutectic powder additive as sintering aid to reduce TiB 2 Examples of sintering temperatures for ceramics. exist Figure 6 Medium VN / SiC / B4 C is a eutectic system, SiC, VN and B 4 The C component can form a eutectic reaction, and the preparation formula of the VN / SiC / B4C eutectic powder is 18-22mol% VN, 46-54mol% B4C, 26-34mol% SiC.VN, SiC and B4C powder according to the component 18- Mix 22mol% VN, 46-54mol% B4C, and 26-34mol% SiC, and stir to obtain eutectic powder. The eutectic powder is used as a raw material, and is pressed into a cylindrical green body with a diameter of 5-20 mm under a pressure of 10-20 MPa. Then in a small DC electric arc furnace with a rated voltage of 100V and a current of 600A, it is melted in an Ar atmosphere of 20cmHg. The phases of the prepared eutectic composite ceramics are C, VB 2 , SiC and B 4 C, the eutectic melting temperature is 1870±20°C, the microstructure is rod-like structure, VB with a diameter of 600nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com