High accuracy non-contact tri-dimensional facial type measuring device

A measuring device, non-contact technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as difficult to measure substances that cannot be directly contacted, unable to measure fine surface microscopic surface, unable to measure fine and complex surfaces, etc. Achieve low cost, reduce measurement error, and reduce Abbe error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 A high-precision non-contact three-dimensional surface measurement device with a counterweight

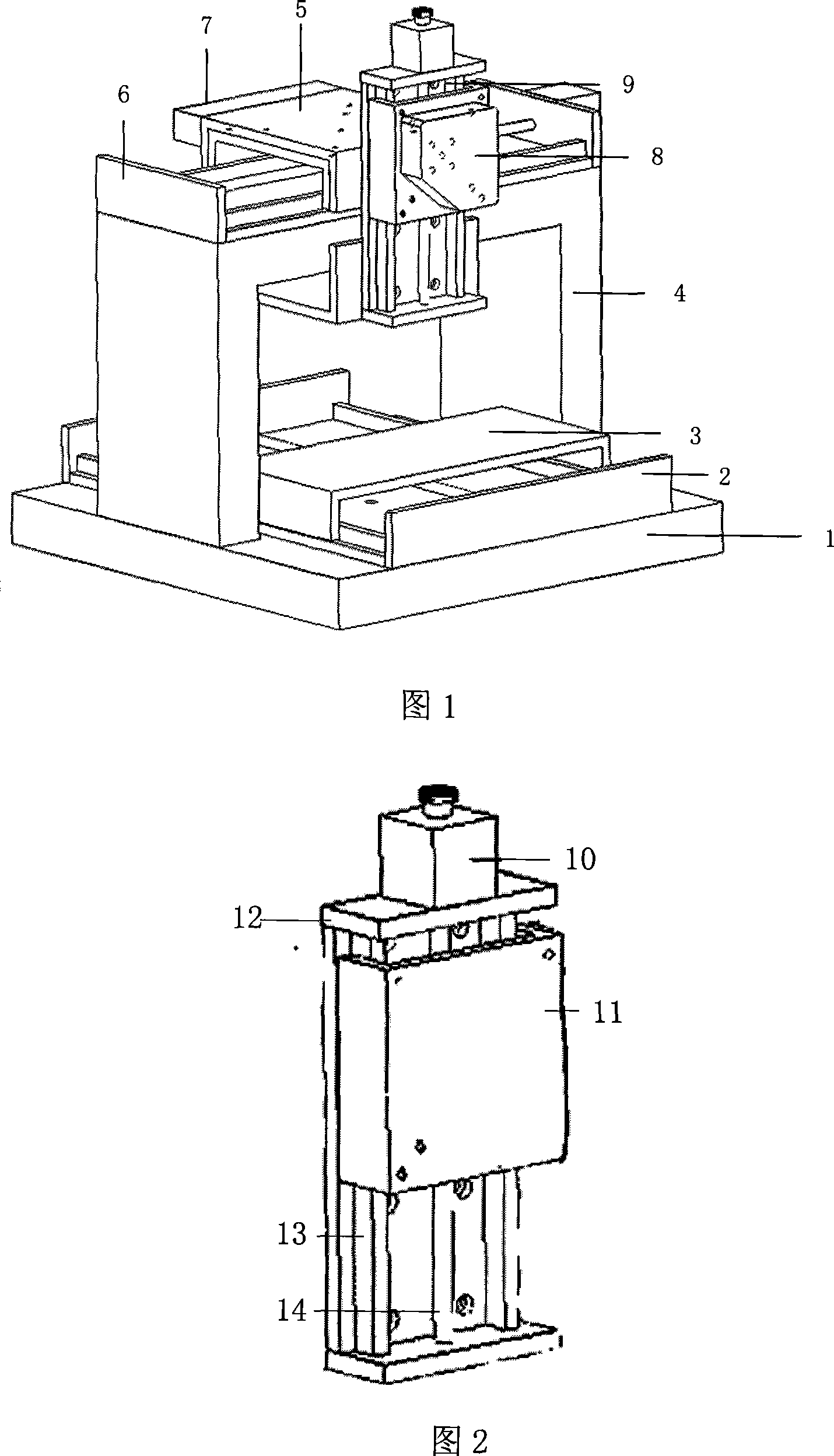

[0044] It can be seen from Figure 1 that:

[0045] The gantry bracket 4 is fixed on the base 1 and is perpendicular to the base 1 ; the X-direction movement unit 2 is also installed on the base 1 ; the working table 3 is installed on the X-direction movement unit 2 . The X-direction motion unit 2 drives the object under test to make X-direction reciprocating motion during the dynamic measurement process;

[0046] The Y-direction movement unit 6 is fixed above the gantry support 4;

[0047] The Z-direction mounting frame 5 is installed on the Y-direction motion unit 6, the Z-direction motion unit 9 is installed on the Z-direction mounting frame 5, and the laser triangulation measurement sensor 8 is fixed on the Z-direction motion unit 9;

[0048] The counterweight 7 is made of steel and has a rectangular parallelepiped shape. It is installed on the Z-direction ...

Embodiment 2

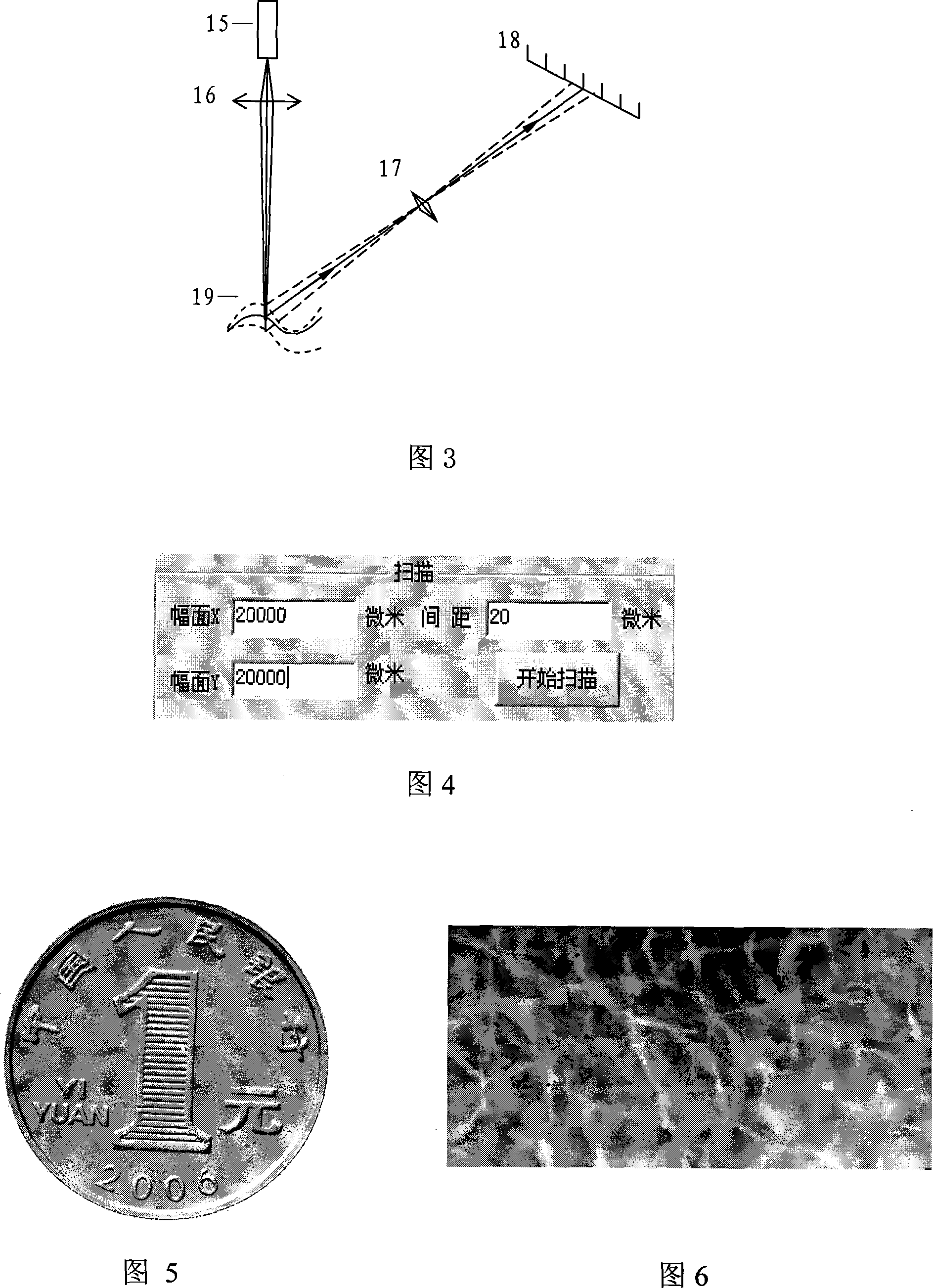

[0056] Embodiment 2 An implementation of the Z-direction motion unit

[0057] Fig. 2 is a schematic diagram of the Z-direction motion unit. The sensor is installed on the motion platform 11, and the sensor is moved by the motion platform 11. The motion unit installation base 12 is used to be fixed on other components, and the motion platform 11 performs linear reciprocating motion on the support of the high-precision linear guide rail 13, which can ensure the straightness of the motion platform 11. The screw rod 14 can rotate under the drive of the drive motor 10 of the motion unit, and the screw rod 14 and the motion platform 11 constitute a worm gear component that can drive the motion platform 11 to move.

Embodiment 3

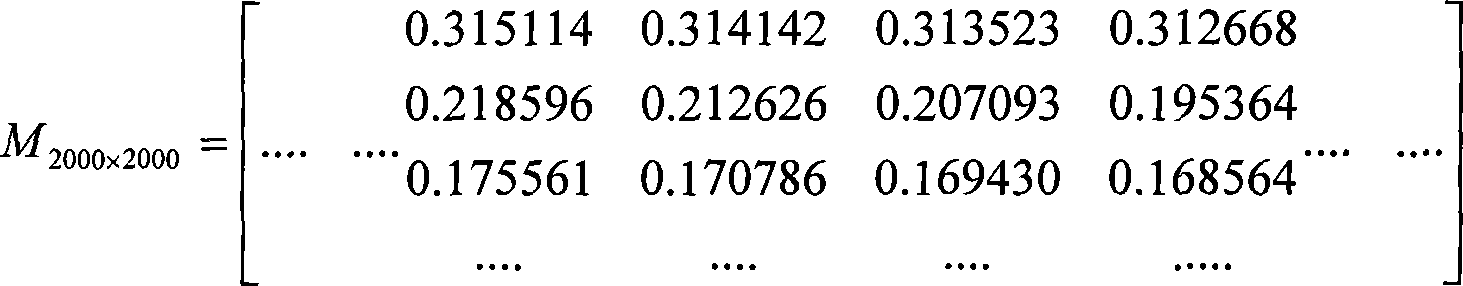

[0058] Embodiment 3 hard material---coin face shape measurement

[0059] 1. Measurement preparation

[0060] 1) Place the 1 yuan coin to be tested on the working platform of the measuring device described in Example 1, face up.

[0061] 2) Adjust the scanning head to the specified position, set the scanning format size, and set the corresponding parameters (X=20000 microns, format Y=20000 microns, spacing=20 microns) in the control computer control software.

[0062] 3) Start the rapid positioning function, that is, the system performs a zigzag rapid sampling movement within the measured range, and analyzes the places where the system may cross the boundary.

[0063] 4) Adjust the relative position between the measurement sensor and the measured object, and obtain the relative height data value of the "zigzag" scanning area, which is 0.011mm-0.013mm. If it exceeds the measurement range of the sensor, " -------" data, that is, invisible data, by analyzing the distribution of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com