Monostable self-locking type air gas variable permanent magnet operation device

A permanent magnet operation, self-locking technology, applied in electrical components, high-voltage air circuit breakers, power devices inside switches, etc. The problem of increasing the stroke of the moving iron core of the magnetic mechanism can reduce the contact collision and bounce, reduce the excitation current, and increase the starting ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

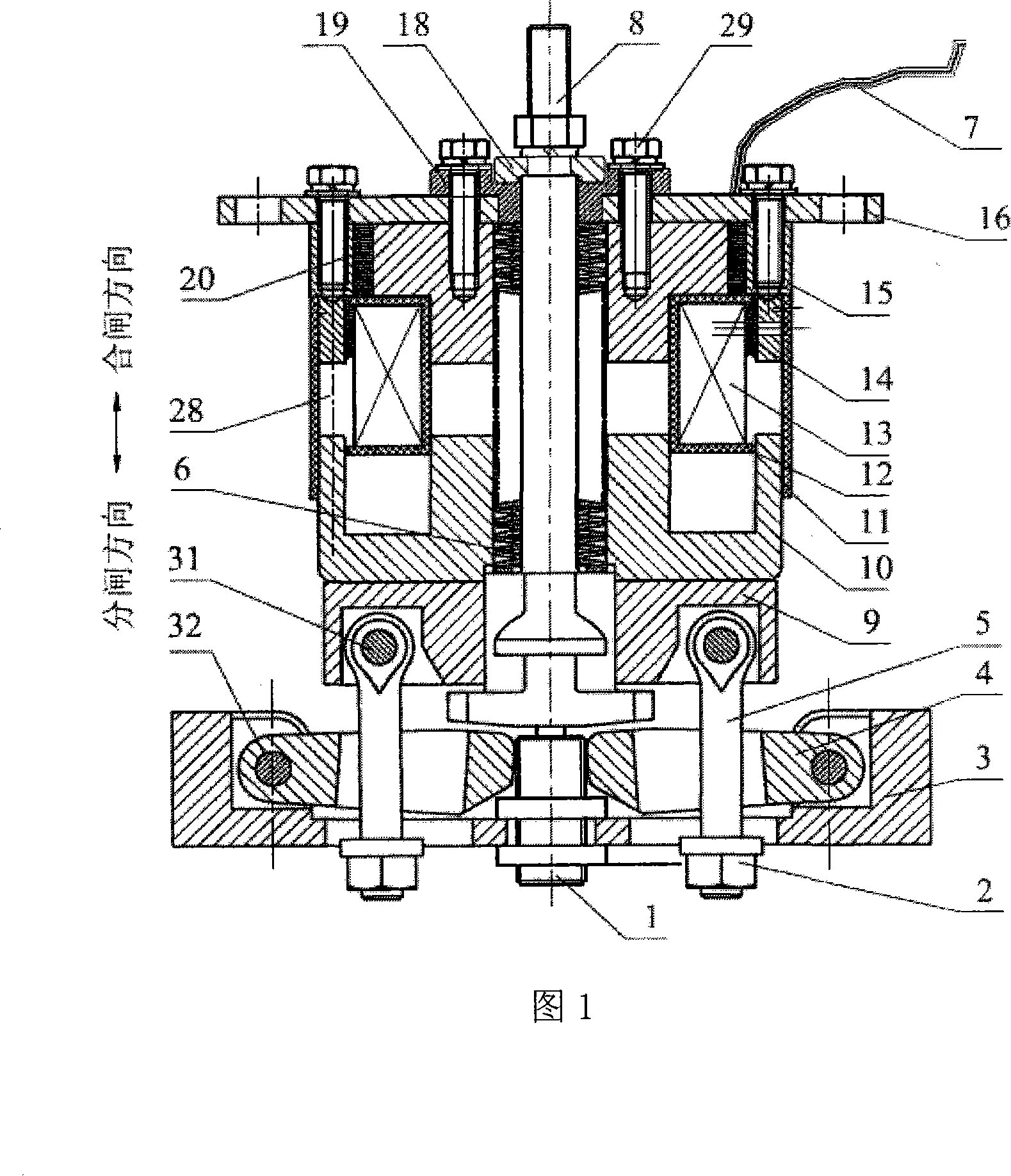

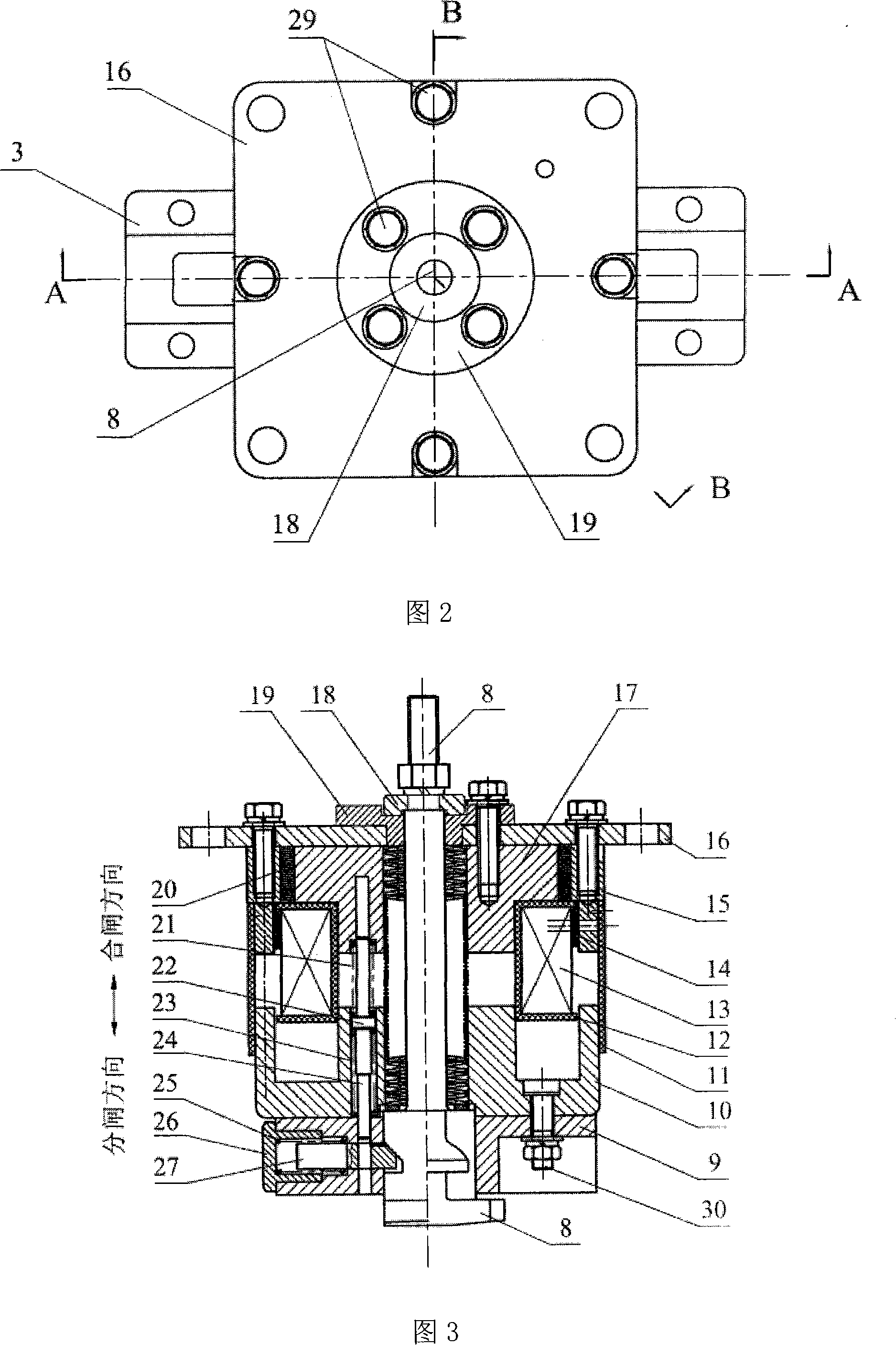

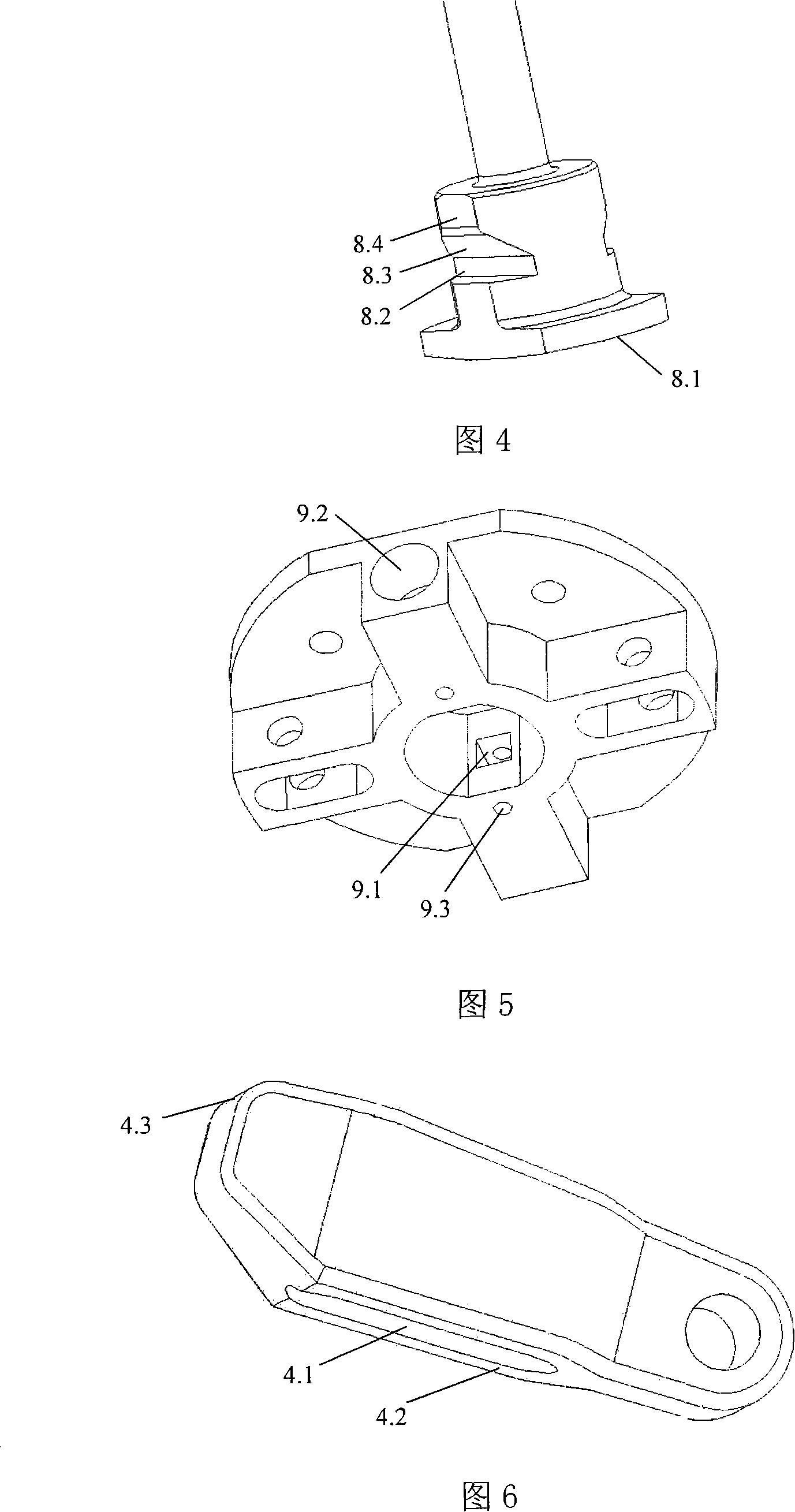

[0025] The invention provides a monostable self-locking variable air gap permanent magnet operating mechanism suitable for large opening distance and high voltage circuit breaker, which is mainly composed of four major systems: magnetic circuit system, transmission system, locking system and support system. .

[0026] In the monostable self-locking variable air gap permanent magnet operating mechanism shown in Fig. 1, Fig. 2 and Fig. 3, the magnetic circuit system is axisymmetric, mainly composed of a moving iron core 10, an outer static iron core 15, an inner static Iron core 17 and permanent magnet 20 form. The permanent magnet 20 is embedded between the inner static iron core 17 and the outer static iron core 15; the electromagnetic coil 13 is embedded in the coil groove formed between the inner static iron core 17, the outer static iron core 15 and the moving iron core 10, And be fixed by epoxy resin ring 14 and inner static iron core 17, outer static iron core 15, guard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com