Novel control method for ultrasonic sensor sensibility and aftershock and novel ultrasonic sensor

A control method and ultrasonic technology, applied in the field of distance measuring sensors, can solve the problems of reducing production efficiency, increasing costs, and increasing costs of enterprises, and achieving the effects of improving applicability and qualification rate, saving costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

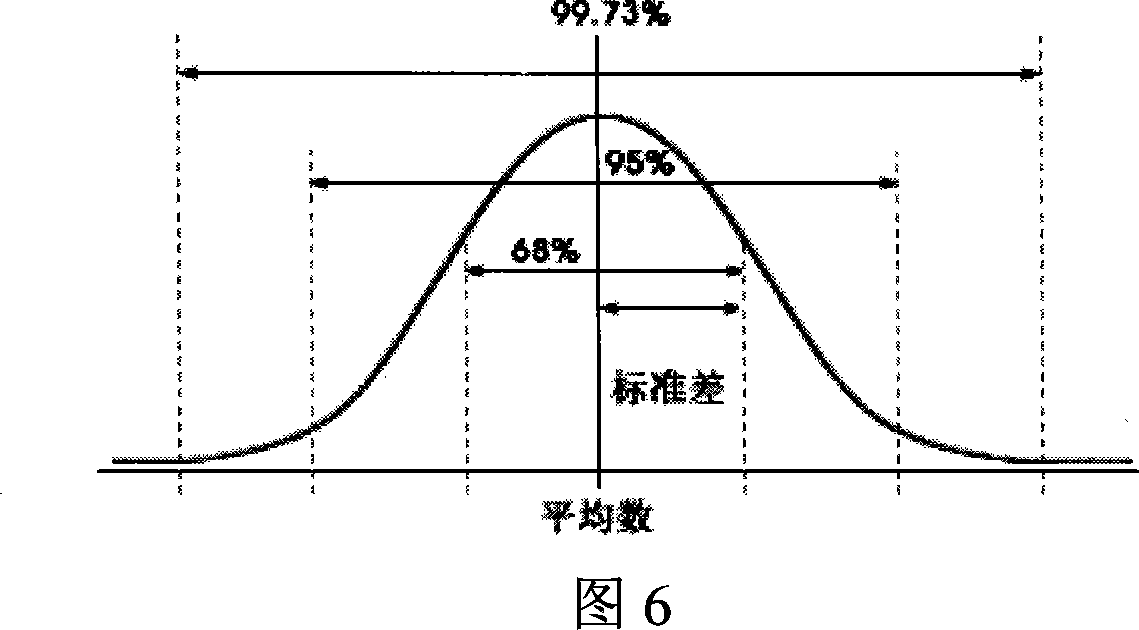

[0022] As shown in Figure 5, a new control method for the sensitivity and aftershock of an ultrasonic sensor is to change the prestress of the piezoelectric chip 2 mechanically, that is, to change the end surface of the pressure block 5 connected to the adjustment device 10 with the pressure adjustment device 10. The distance between the electrical chip 2 is to change the pressure on the piezoelectric chip 2, so that the internal stress of the piezoelectric chip 2 changes, and the lead-out pin 4 of the ultrasonic sensor is connected to an oscilloscope or a frequency scanner. Under monitoring, observe the waveform or frequency displayed by the oscilloscope or frequency sweeper to keep the adjusted ultrasonic sensor within a consistent waveform or frequency range, and finally use the adjusted circuit board 3 and the adjustment device 10 with the silicone filler 9 again Carry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com