Integrated transportation control for wafer fabrication facility

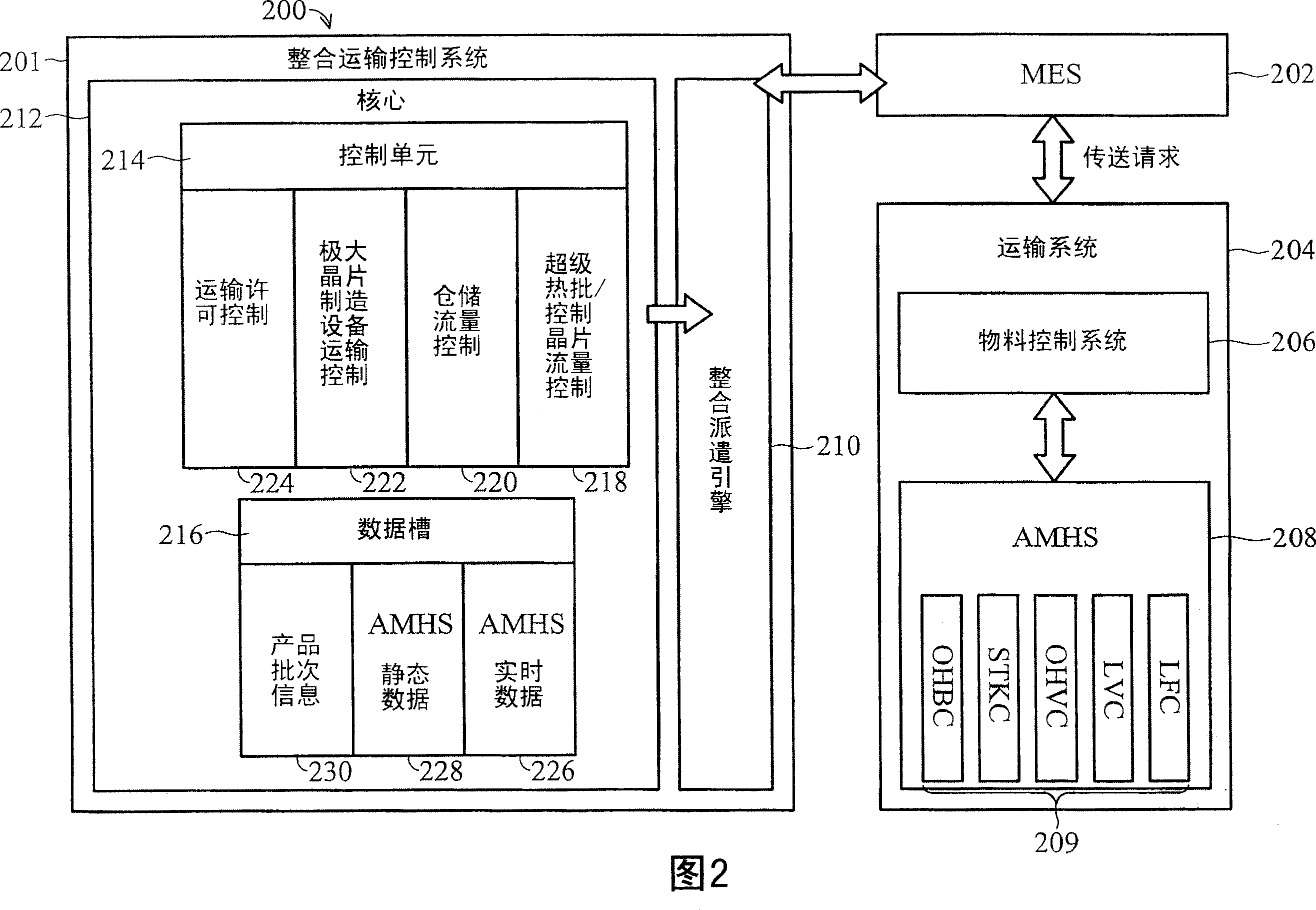

A technology of factory automation and transportation system, applied in the direction of comprehensive factory control, general control system, control/regulation system, etc., can solve the problem of not considering the real-time traffic status of the wafer manufacturing plant, and achieve the effect of eliminating traffic jams and improving transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

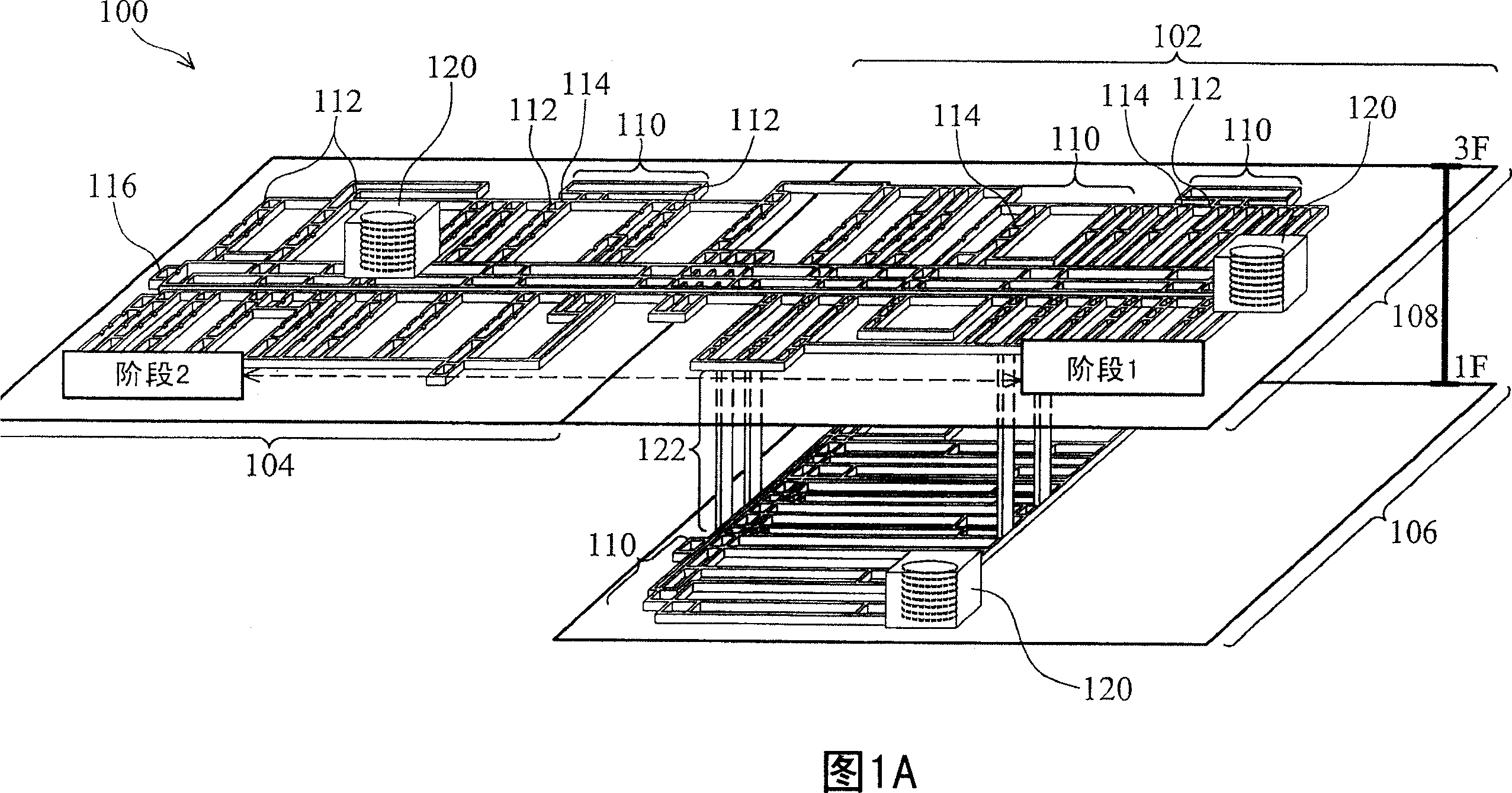

[0054] FIG. 1A shows a schematic diagram of a 300 micron wafer fabrication plant according to an embodiment of the present invention. Wafer fabrication facility 100 may be considered a "very high level" when it includes multiple stages, respectively denoted by reference numerals 102 and 104 as shown in FIG. Giga fab". A "cross-floor transfer job" involves transferring a cassette, or FOUP, from one of the floors 106, 108 to the other. Similarly, a "cross-stage transfer job" involves transferring a cassette, or FOUP, from one of the stages 102 and 104 to the other stage.

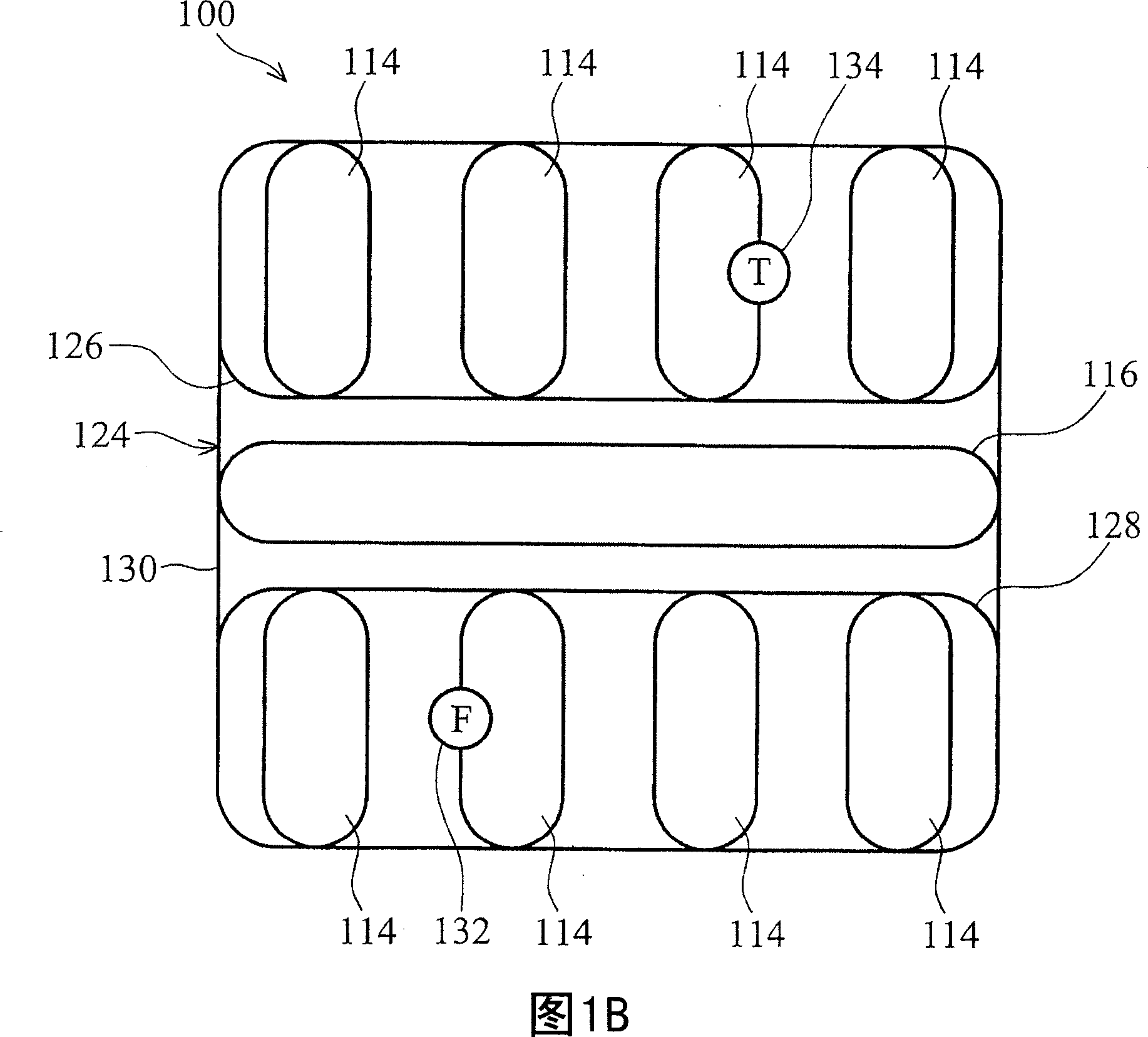

[0055] Each stage 102 , 104 includes a plurality of bays 110 , each bay 110 including process tools or equipment 112 . The equipment 112 in each bay 110 is interconnected to each other by an overhead transport (OHT) system 114 within a bay. The bays 110 are interconnected with each other by an interbay OHT system 116 which will hereinafter be considered a so-called super highway. As known to those skilled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com