Gravure on-line silk-screen technics and the equipment thereof

A printing and thread technology, applied in printing, printing machines, printing devices, etc., can solve the problem of not finding processing technology, and achieve the effect of low cost, less waste and exquisite printed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The gravure in-line screen printing process in this preferred embodiment includes the following steps in sequence: pre-press scheme design, printing raw material processing, in-line gravure screen printing, hot stamping embossing, and quality inspection.

[0025] The above-mentioned pre-press scheme design, printing raw material processing, bronzing embossing and quality inspection are all the same as the steps in the traditional gravure printing or silk screen printing process. And the invention point of this patent application lies in gravure printing in-line screen printing step.

[0026] The above gravure in-line silk screen printing steps include three gravure printing and one drum type silk screen printing.

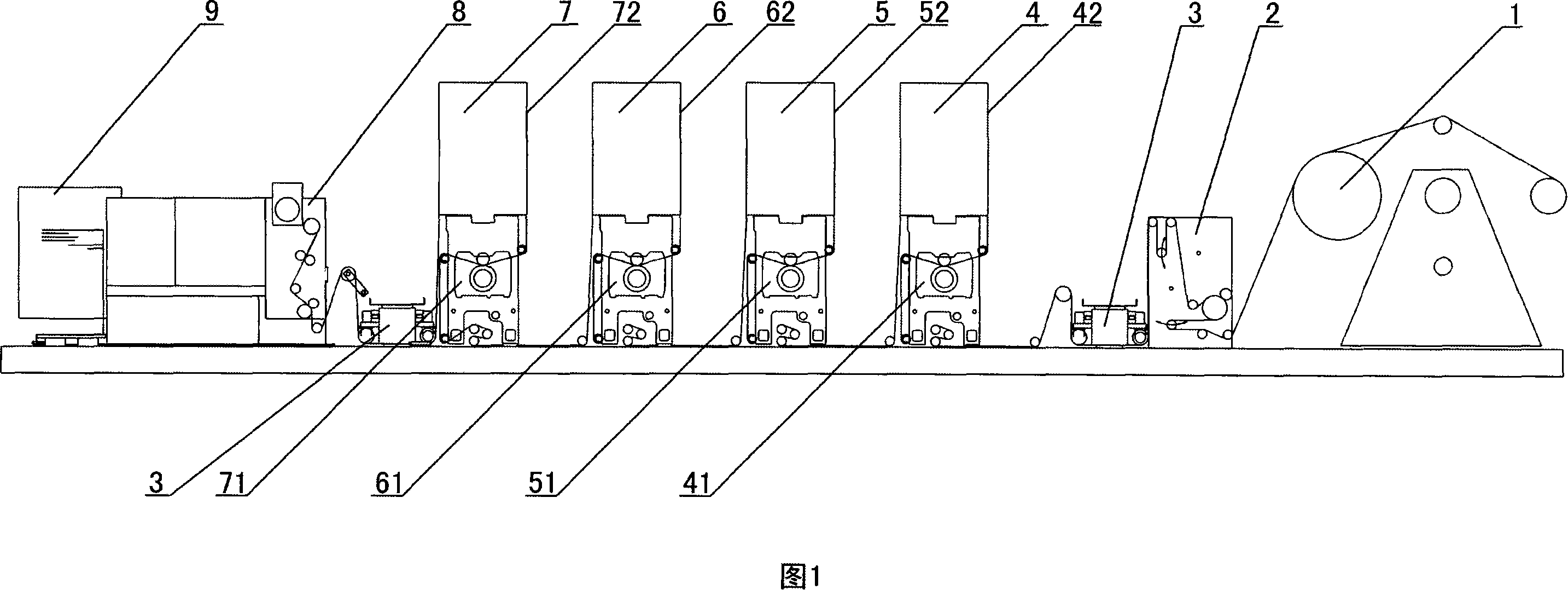

[0027] As shown in Figure 1, a gravure in-line cylinder screen printing equipment used in the above gravure in-line screen printing process, sequentially includes an unwinding device 1, an introduction device 2, a deviation correction device 3, four printing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com