Energy conservation environmental protection heavy oil dispensing machine

An energy-saving and environmentally friendly heavy oil technology, which is applied in mechanical equipment, gas/liquid distribution and storage, pipeline systems, etc., can solve the problems that emulsified heavy oil cannot be effectively promoted, emulsified heavy oil is not very common, and the calorific value of emulsified heavy oil is reduced, so as to achieve saving Effects of heavy fuel oil consumption, improvement of competitiveness, and reduction of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

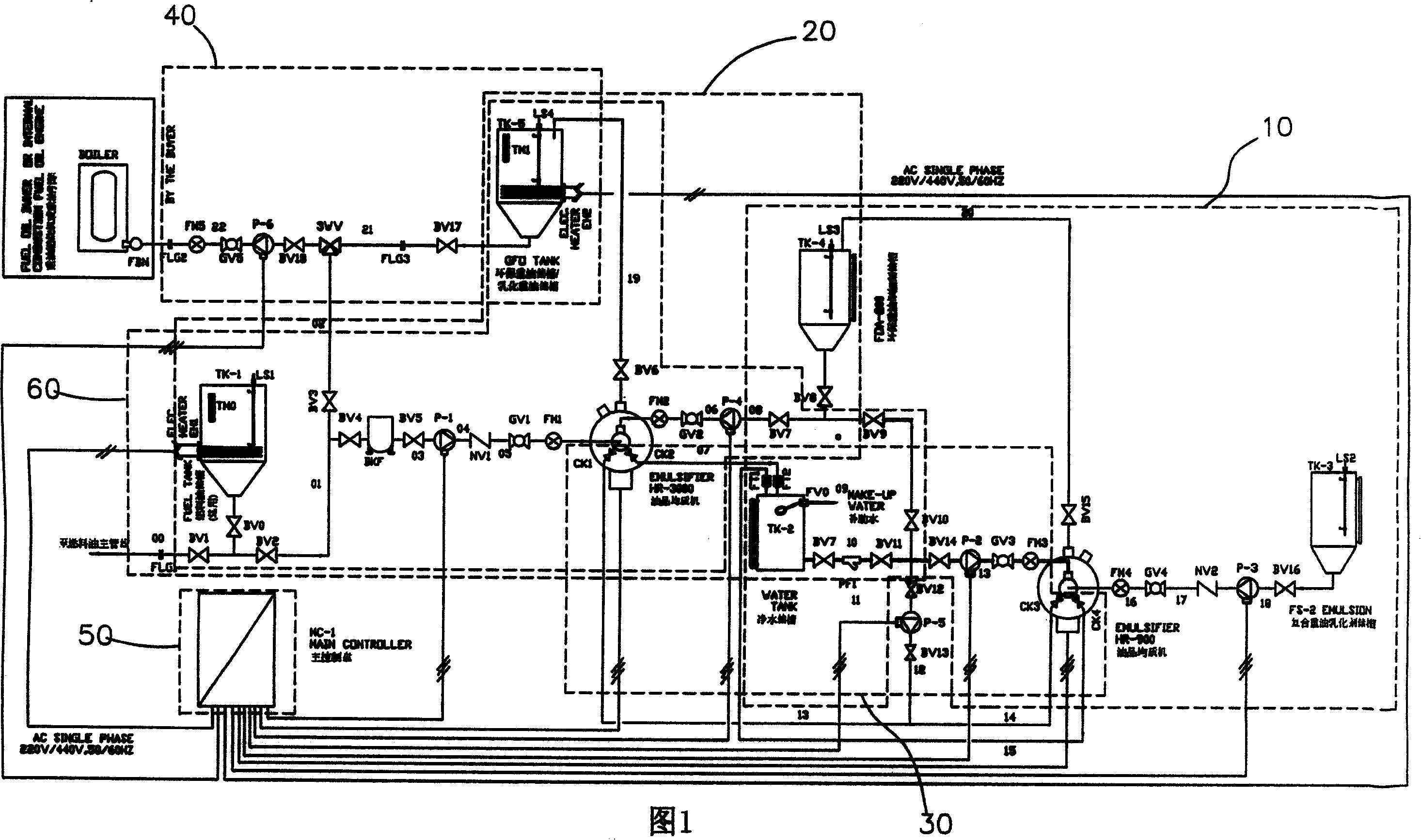

[0081] Embodiment 1: Preparation process of environmental protection heavy oil additive

[0082] a. Before operation, first inject compound heavy oil emulsifier FS-2 into TK-3, inject clean water into TK-2, and inject heavy oil into TK-1, or close BV0, open BV1 and BV2 directly by The external heavy oil storage tank introduces heated heavy oil;

[0083] b. Open the clean water output valves BV19, BV11, BV14, BV12, BV13, and GV3

[0084]c. Turn on the cooling water delivery pump P-5 to allow the cooling water to flow through the shaft seal cooling pipeline 14 and enter the shaft seal cooling cabin of the oil homogenizer HR-900 through the cock valve CK3 to cool the shaft seal, and then pass through the cock valve CK4 And the filter FT1 returns to the clean water storage tank TK-2; the cooling water also enters the shaft seal cooling cabin of the oil homogenizer HR-3000 via the pipeline 13 through the cock valve CK1 to cool the shaft seal, and then circulates The valve CK2 and...

Embodiment 2

[0089] Example 2: Energy-saving and environment-friendly heavy oil preparation process

[0090] a. Open ball valves BV0 (or BV1), BV2, BV4, BV5, BV6, BV7, BV8 and gate valves GV1 and GV2;

[0091] b. Start the heavy oil delivery pump P-1, oil homogenizer HR-3000, and environmental protection heavy oil additive delivery pump P-4, and start to mix heavy oil and environmental protection heavy oil additive FDA-200 at a ratio of 70-80%: 20-30% The ratio is sent to the oil homogenizer HR-3000 to start blending the energy-saving and environment-friendly heavy oil, and enters the energy-saving and environment-friendly heavy oil storage tank TK-5 along the pipeline 19. When the liquid level of the energy-saving and environment-friendly heavy oil reaches the preset point of the liquid level detector LS4, The electric heater EH2 starts and continues to heat up to heat the energy-saving and environment-friendly heavy oil to 90-100°C, ready to be used by the burner or internal combustion e...

Embodiment 3

[0092] Embodiment 3: fuel oil supply process

[0093] a. Turn on BV17, BV18 and GV5;

[0094] b. Turn the three-way valve 3WV to the position where the pipelines 21 and 22 are connected, and the pipelines 21 and 02 are interrupted

[0095] c. Start the fuel oil transfer pump P-6 to send the energy-saving and environment-friendly heavy oil to the burner FBN or the internal combustion engine, and the combustion system starts to use the energy-saving and environment-friendly heavy oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com