Drying machine

A dryer and drying chamber technology, applied in the invention field of dryers, can solve problems such as user inconvenience, dryer performance degradation, and insufficient air flow, and achieve the effects of ensuring reliability and preventing performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

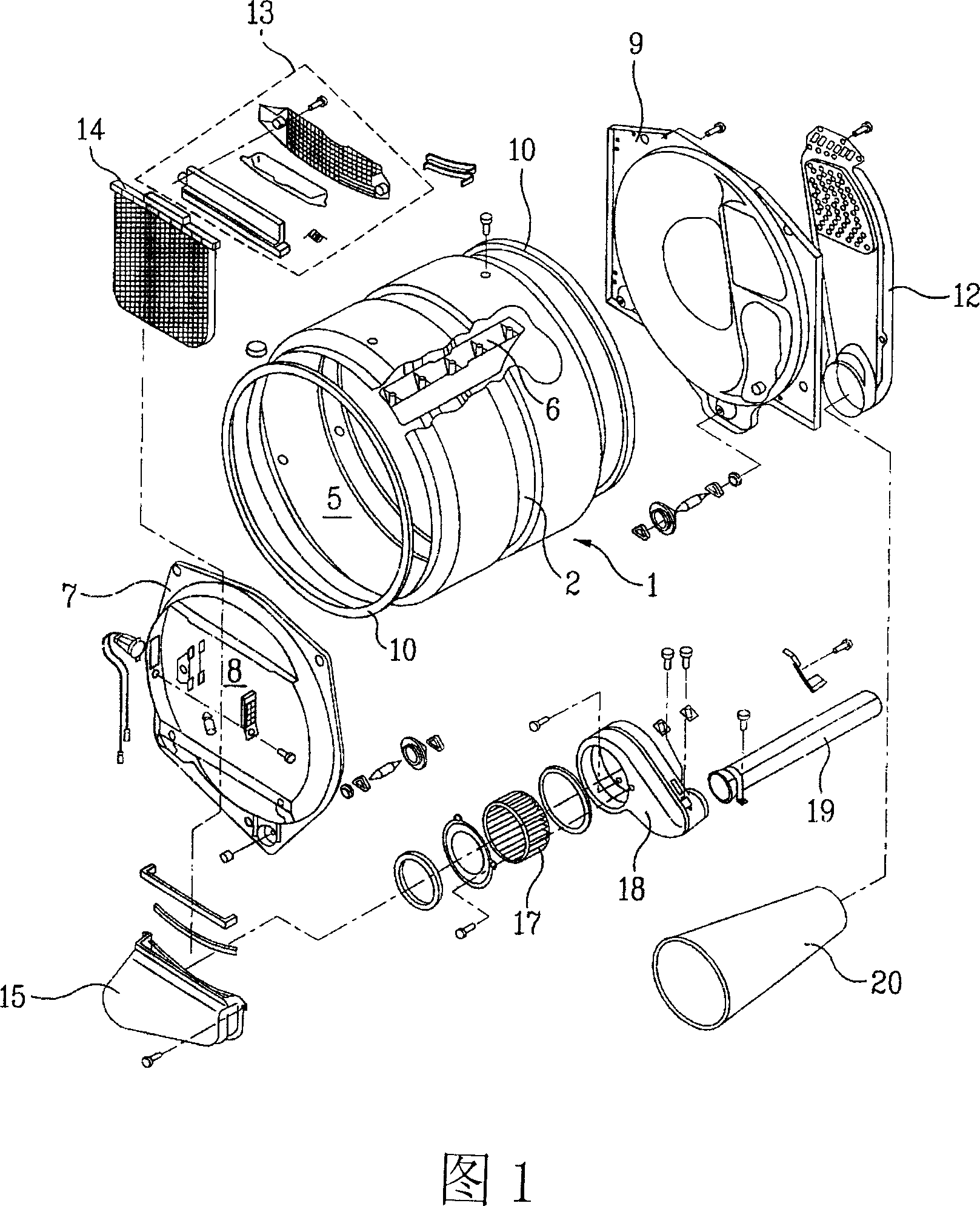

[0037] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention will be described in detail as follows.

[0038] ***Description of symbols for main components in the drawings***

[0039] 1: drum 5: drying chamber

[0040] 14: Lint filter 15: Lint duct

[0041] 110: Drive motor 120: Blowing fan

[0042]130: Pressure sensor 140: Control unit

[0043] 150: display unit 160: alarm unit (alarm)

[0044] In addition, the same reference numerals as in FIG. 1 refer to components having the same functions, and only the characteristic parts of the present invention will be described.

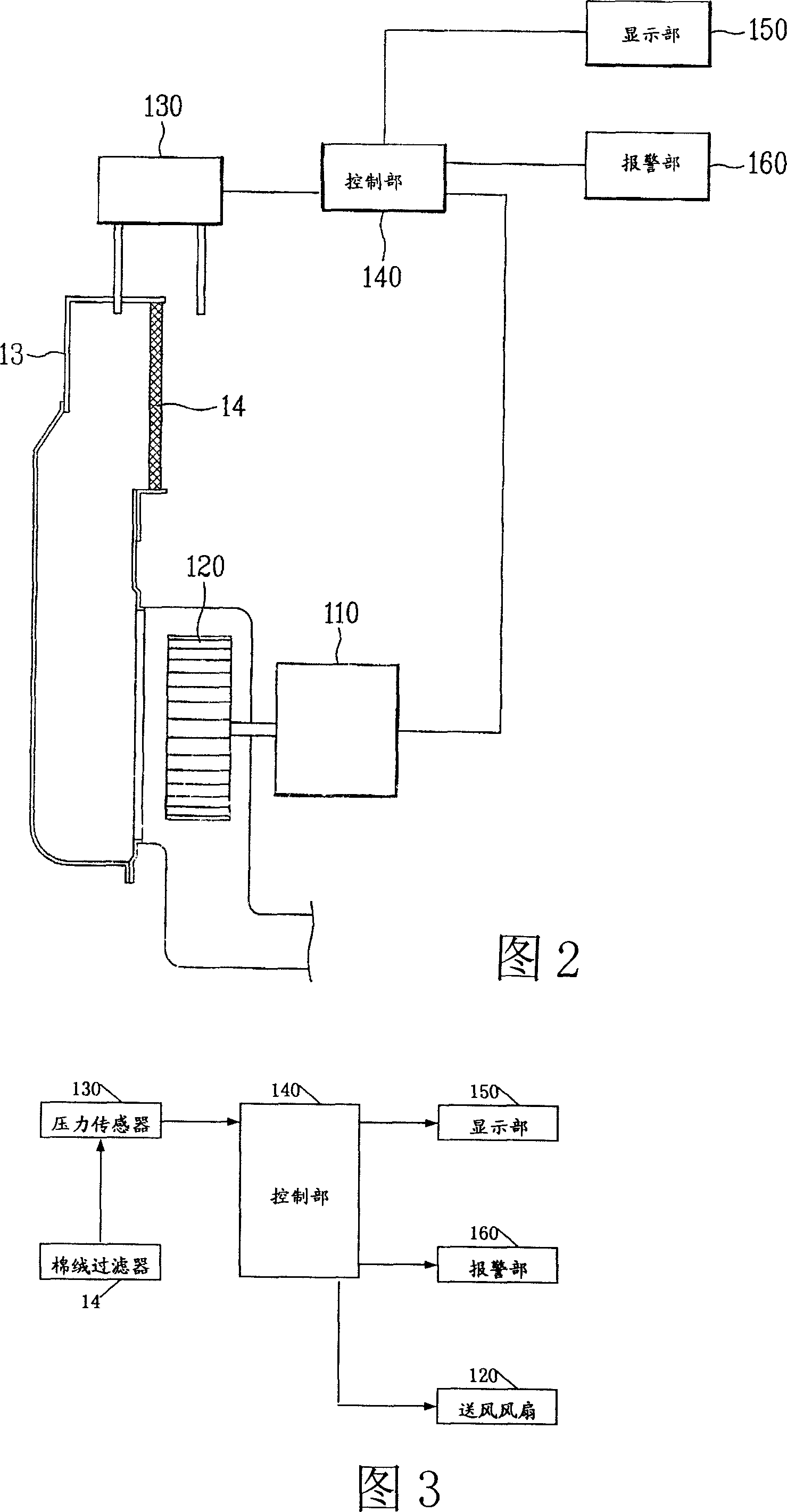

[0045] Referring to Fig. 2 and Fig. 3, the dryer of the present invention is composed of the following parts: a drum 1 with a drying chamber 5; for filtering the air discharged from the drying chamber 5 of the drum 1 The lint filter 14 of the foreign matter in the lint filter; the lint air chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com