Crown gear train type spacing mechanical arm modularization joint

A space manipulator, modular joint technology, applied in manipulators, manufacturing tools, joints, etc., can solve the problems of low output torque per unit mass, high power consumption, high mass, etc., and achieve high overall stiffness, low power consumption, and high quality. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

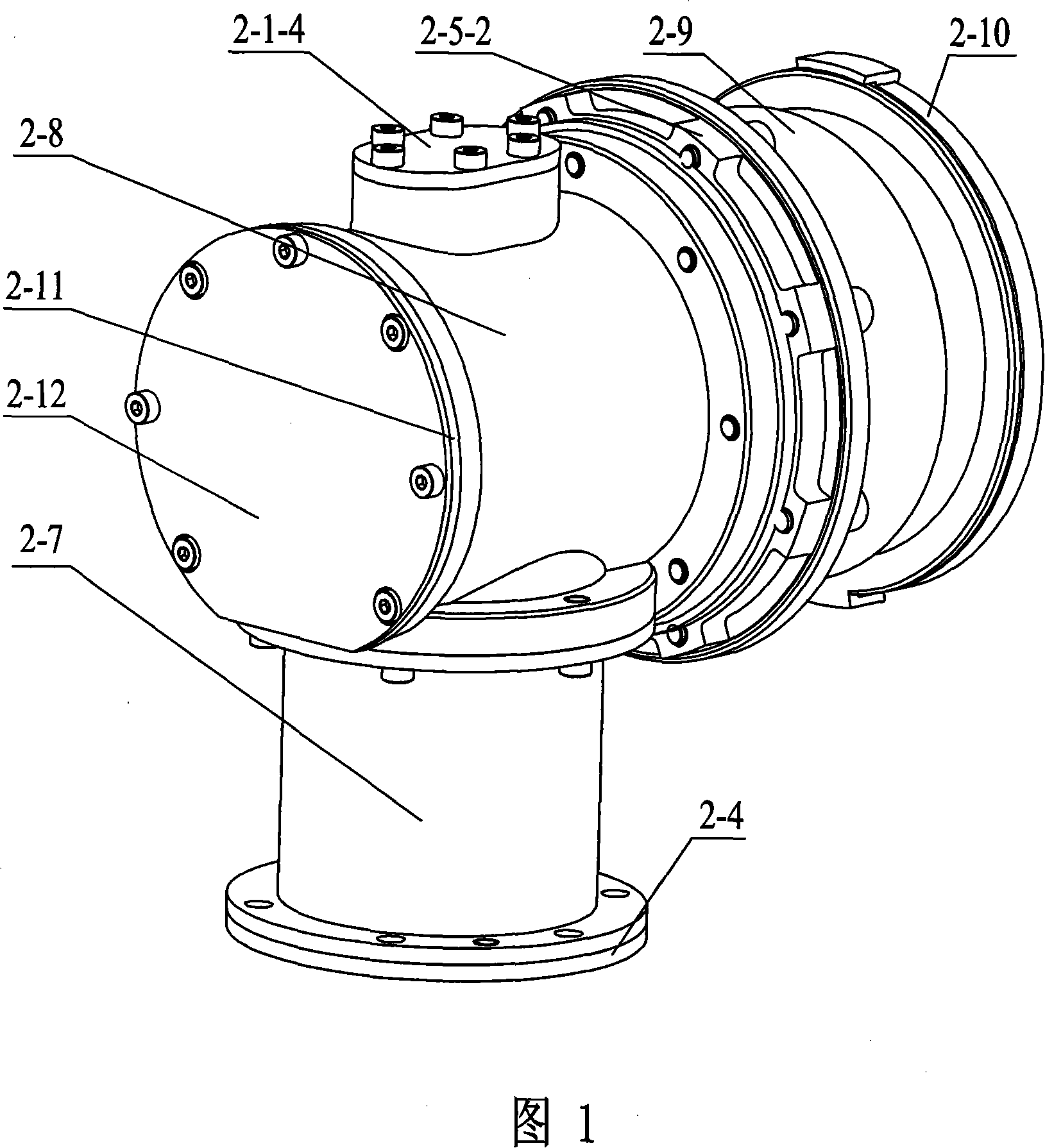

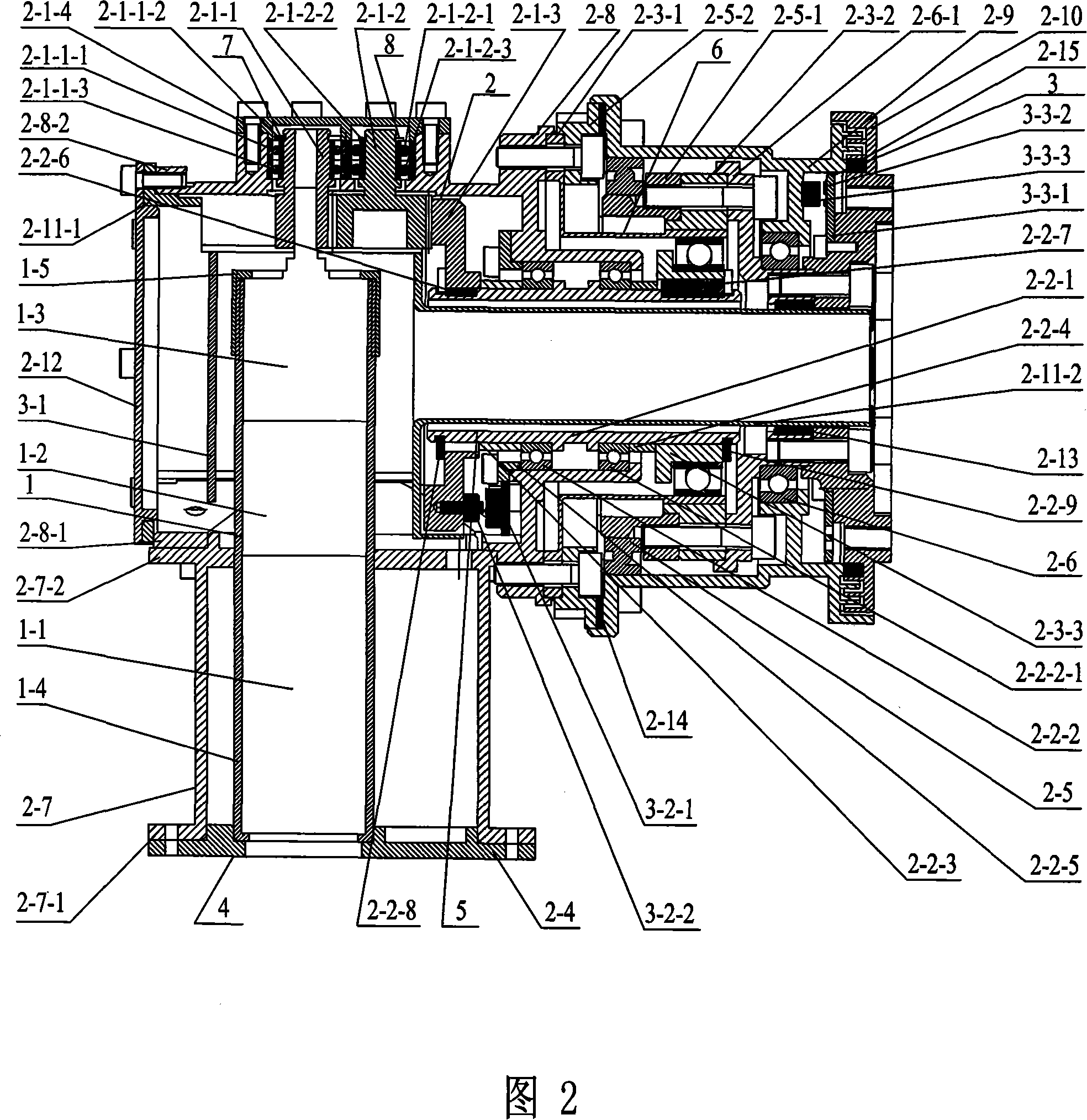

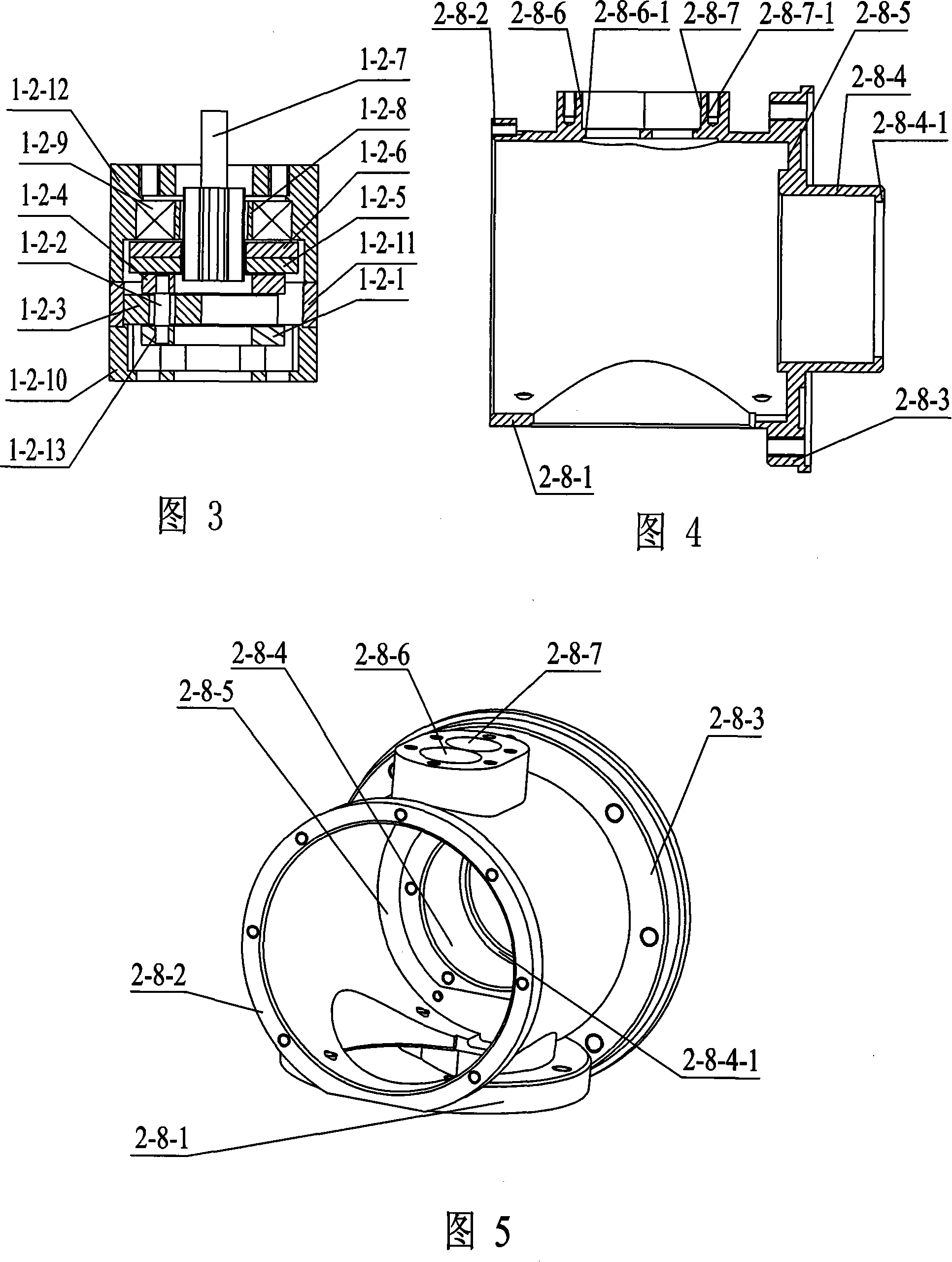

[0007] Specific Embodiment 1: As shown in Fig. 1, Fig. 2, Fig. 4-10, the modular joint of the crown gear train type space manipulator in this embodiment consists of an outer casing 4, a driving device 1, a joint mechanism 2 and an electrical device 3 Composition, the drive device 1, the joint mechanism 2 and the electrical device 3 are all installed in the outer shell 4, the drive device 1 is connected to the joint mechanism 2, and the electrical device 3 is arranged on the joint mechanism 2; the described joint mechanism 2 is composed of Crown pinion 2-1-1, crown idler 2-1-2, crown gear 2-1-3, first bearing assembly 7, second bearing assembly 8, crown gear system pressure plate 2-1-4 , Hollow transmission shaft device 5, harmonic reducer 6, large thin-wall bearing 2-5, small thin-wall bearing 2-6, large thin-wall bearing inner ring support seat 2-5-1, large thin-arm bearing outer ring stop Ring 2-5-2, small thin-wall bearing inner ring support seat 2-6-1, sleeve 2-11; the sle...

specific Embodiment approach 2

[0009] Specific embodiment two: as shown in Fig. 1, Fig. 2, Fig. 4-10, the outer casing 4 described in this embodiment is composed of a first casing 2-7, a second casing 2-8, and a third casing 2-9. , joint rear end cover 2-12, output flange 2-10, motor sleeve fixing base 2-4, the No. 2 flange 2-7 of the first shell on the upper end of the first shell 2-7 -2 is connected with the No. 1 flange plate 2-8-1 of the second shell on the lower side wall of the second shell 2-8, and the No. 3 flange plate 2-8 of the second shell on the right end of the second shell 2-8 -3 is connected with the No. 1 flange plate 2-9-1 of the third housing at the left end of the third housing 2-9, and the motor sleeve fixed base 2-4 is connected with the No. 1 housing No. 1 at the lower end of the first housing 2-7. The flange plate 2-7-1 is connected, the joint rear end cover 2-12 is connected with the second shell No. 2 flange plate 2-8-2 on the left end of the second shell 2-8, and the output flange...

specific Embodiment approach 3

[0010] Specific embodiment three: As shown in Figure 2, the drive device 1 described in this embodiment consists of a brushless DC motor 1-1, a friction reverse brake 1-2, a planetary reducer 1-3, and a motor sleeve 1- 4 and the motor sleeve cover 1-5, the motor sleeve 1-4 is fixed on the motor sleeve fixed base 2-4, the DC brushless motor 1-1, the friction reverse brake 1- 2. The planetary reducer 1-3 is installed in the motor sleeve 1-4 sequentially from bottom to top, the output end of the DC brushless motor 1-1 is connected to the input end of the friction reverse brake 1-2, and the friction reverse brake The output end of the brake 1-2 is connected to the input end of the planetary reducer 1-3, the motor sleeve cover 1-5 is fixed on the upper end of the motor sleeve 1-4, and the motor sleeve 1-4 is made of titanium alloy material. Both the rear end of the motor sleeve and the inside of the motor sleeve cover are threaded, and the two can be screwed tightly, which is easy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com