Narrow slit and large slit combination type microwave plasma reaction cavity

A microwave plasma and reaction chamber technology, applied in the direction of plasma, electrical components, etc., can solve problems such as uneven electric field distribution, and achieve the effect of expanding the distribution range and uniform electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

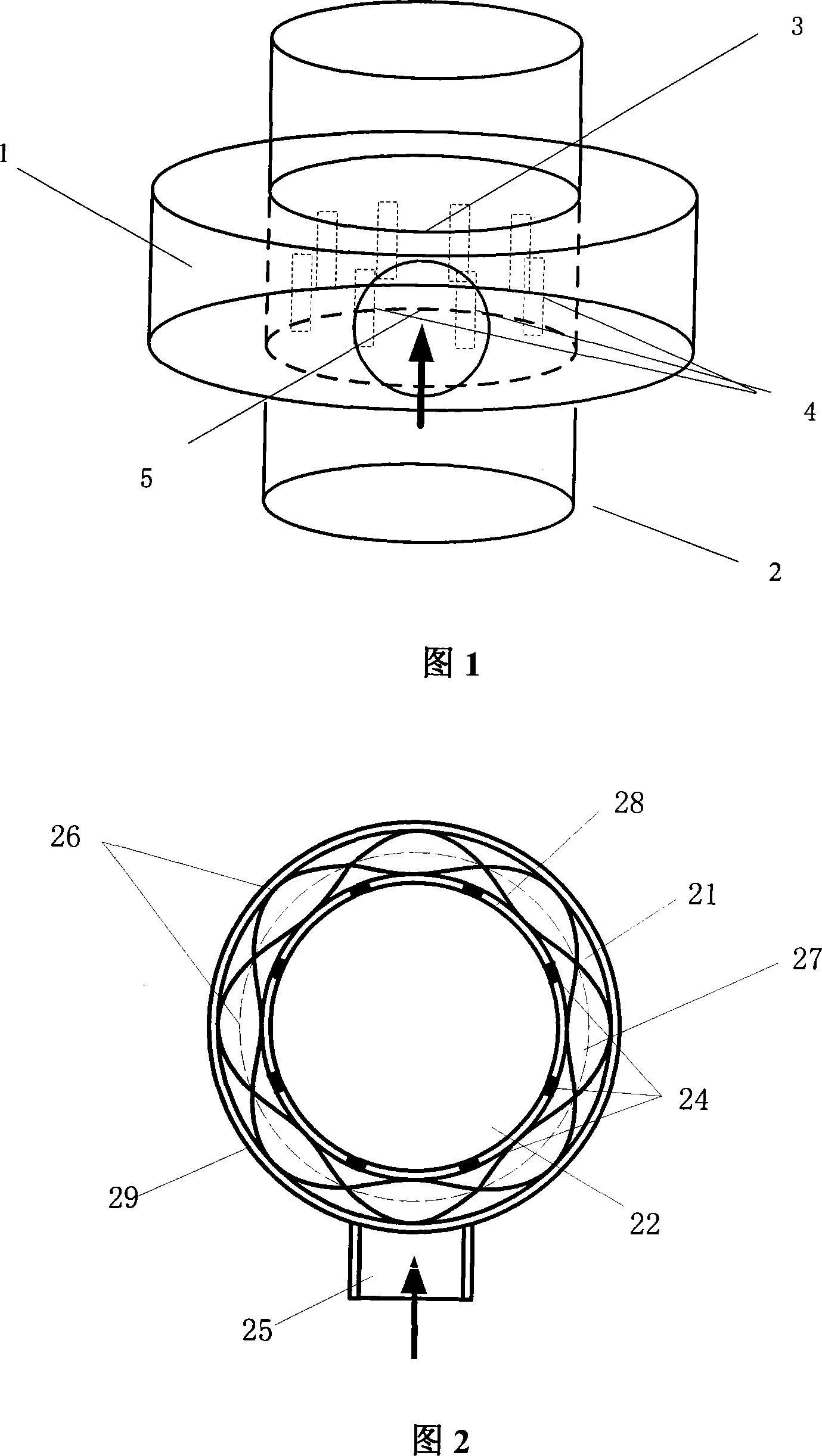

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

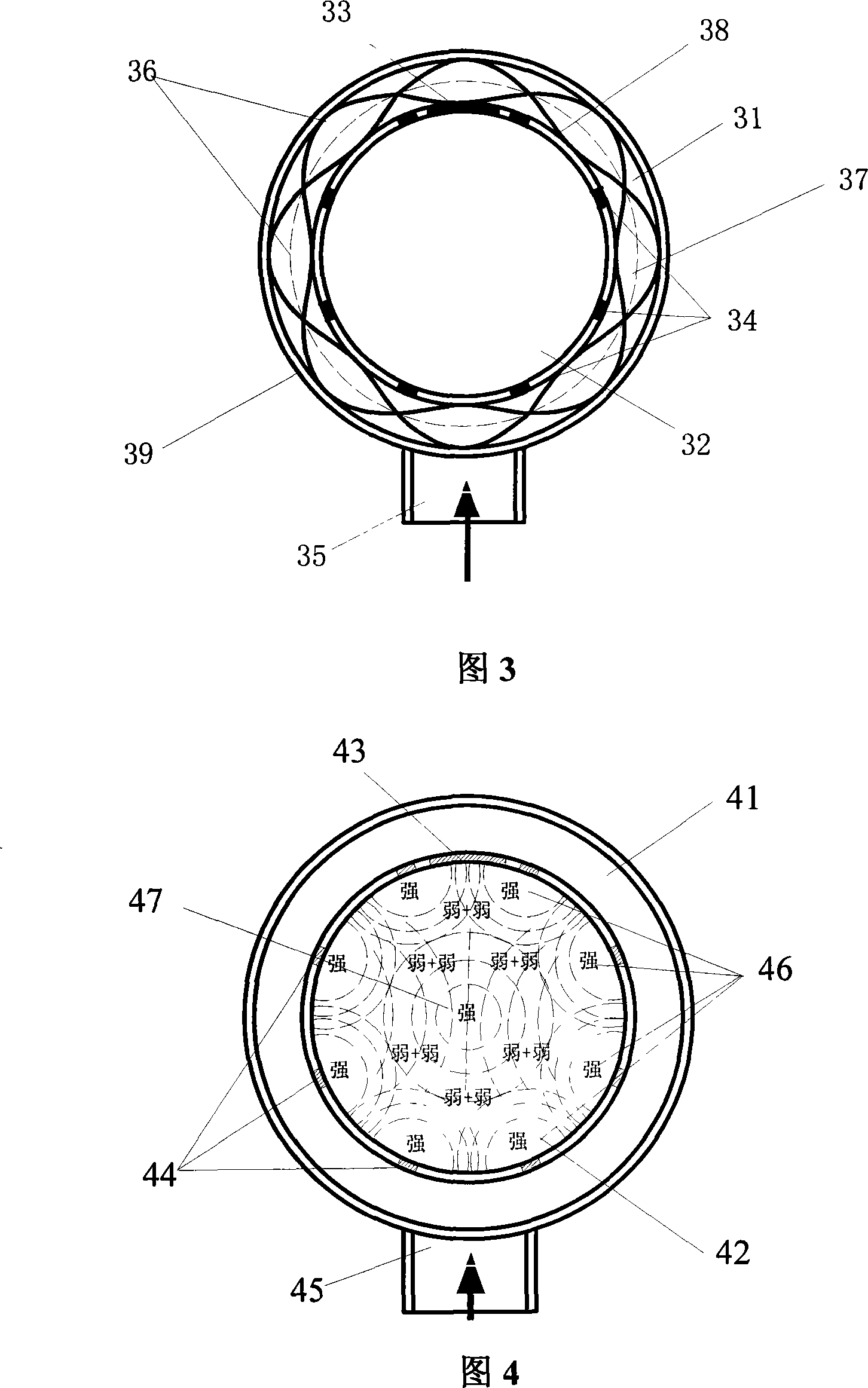

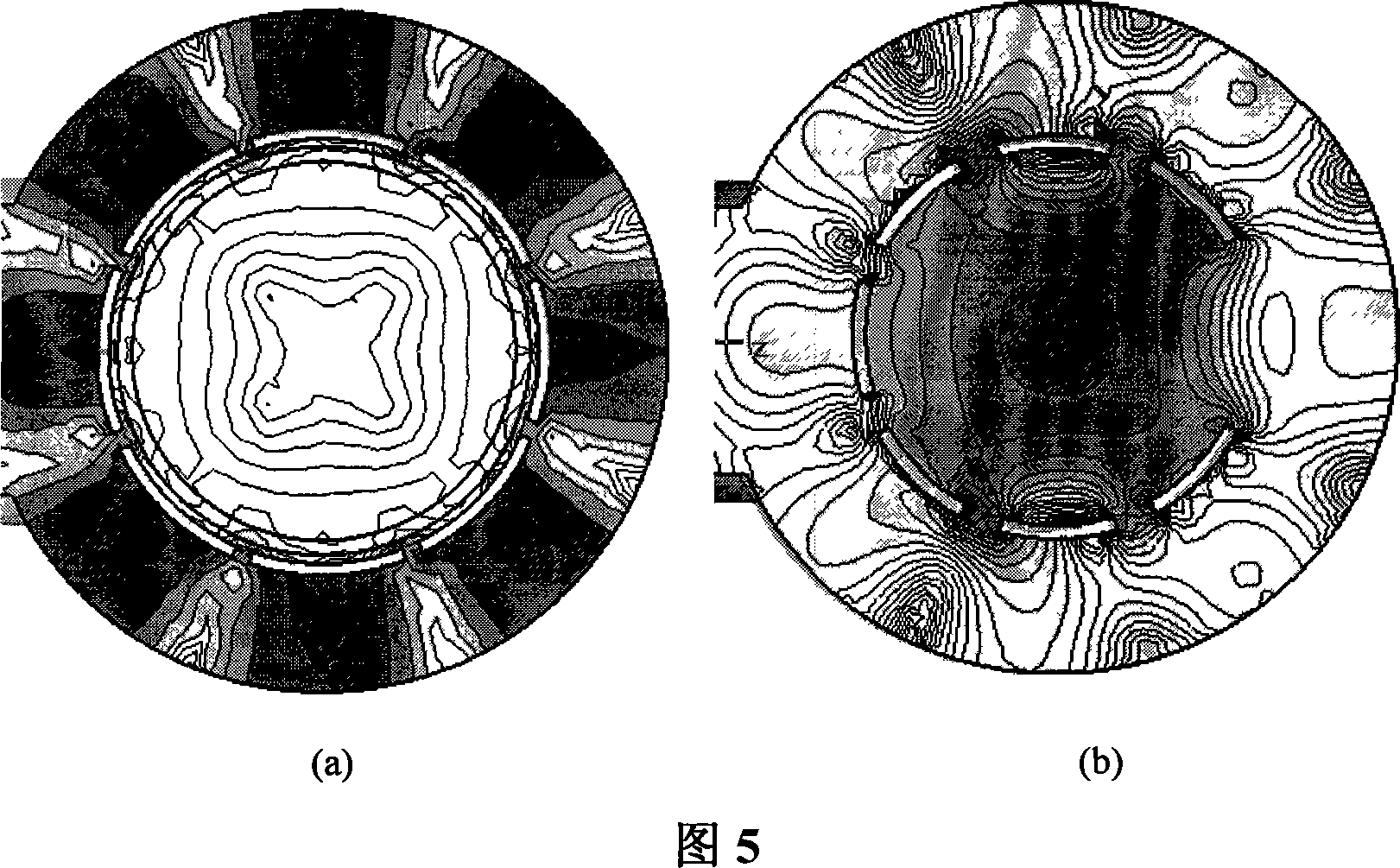

[0021] The structure of an embodiment of the combined slit and large slit microwave plasma reaction chamber proposed by the present invention is shown in FIG. 3 . In this embodiment, the microwave frequency is input at 2.45 GHz, and the reaction chamber 32 is a hollow cylinder placed vertically, and the top and bottom are sealed by detachable flanges (not shown in the figure). In the middle of the cavity, there is a ring waveguide 31 with a rectangular cross section, the inner wall 38 of the ring waveguide coincides with the outer wall of the reaction chamber; the inner wall of the ring waveguide has eight narrow holes corresponding to the number of nodes of the four standing waves in the ring waveguide. slit 34, the position of the slit is just at the node of the standing wave; the outer wall of the ring waveguide 31 has a through hole 35, which is connected to the squ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com