Oil-gas automatic discharging cyclone gas-liquid separator

A technology of automatic discharge and liquid separator, which is applied in the directions of cyclone devices, separation methods, and dispersed particle separation to achieve the effect of low operating cost and improved effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

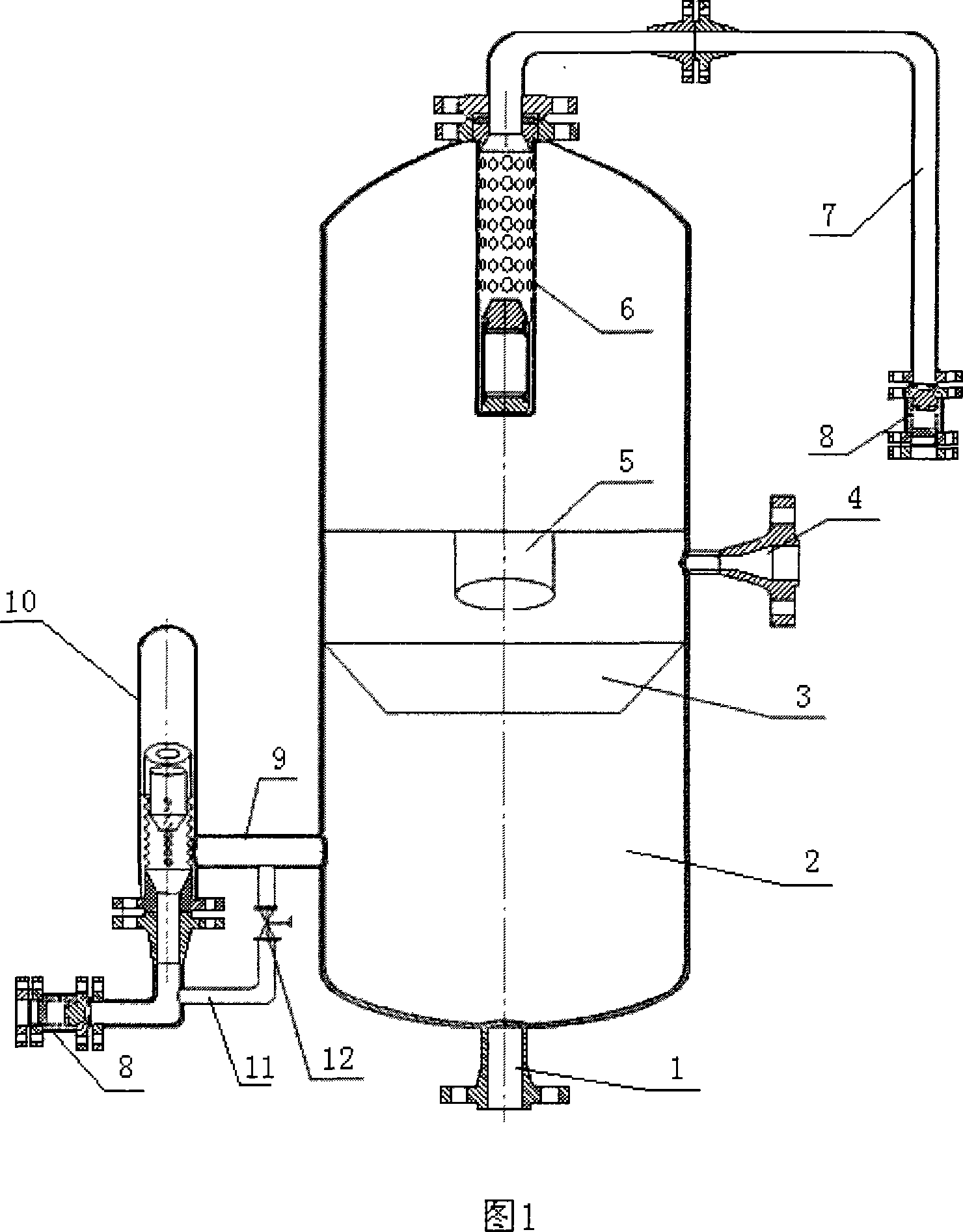

[0021] Embodiment 1: Refer to Fig. 1. Oil and gas automatic discharge cyclone gas-liquid separator, the tank body 2 is a vertical airtight tank with a diameter of 1.5 meters and a height of 4 meters. There is a sewage outlet 1 at the bottom of the tank body 2 . There is an inlet 4 with an inner diameter of 80 mm in the middle part of the tank body 2 meters away from the bottom. There is a cyclone 3 in the tank body 2 at 1.5 meters away from the bottom of the tank body. There is a gas phase introduction port 5 in the tank body 2 at a distance of 1.8 meters from the bottom of the tank body. A gas phase automatic discharge device 6 is fixed on the top of the tank body 2 . The gas phase automatic discharge device 6 is connected with a gas phase discharge pipeline 7 with an internal diameter of 50 mm. The gas phase discharge pipeline 7 is connected with a gas phase outlet constant pressure flow control valve 8 . The lower part of the tank body 2 is connected with a liquid disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com