Auto-feeder

An automatic feeding and sliding block technology, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of high manufacturing cost, complex structure of automatic feeding machine, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

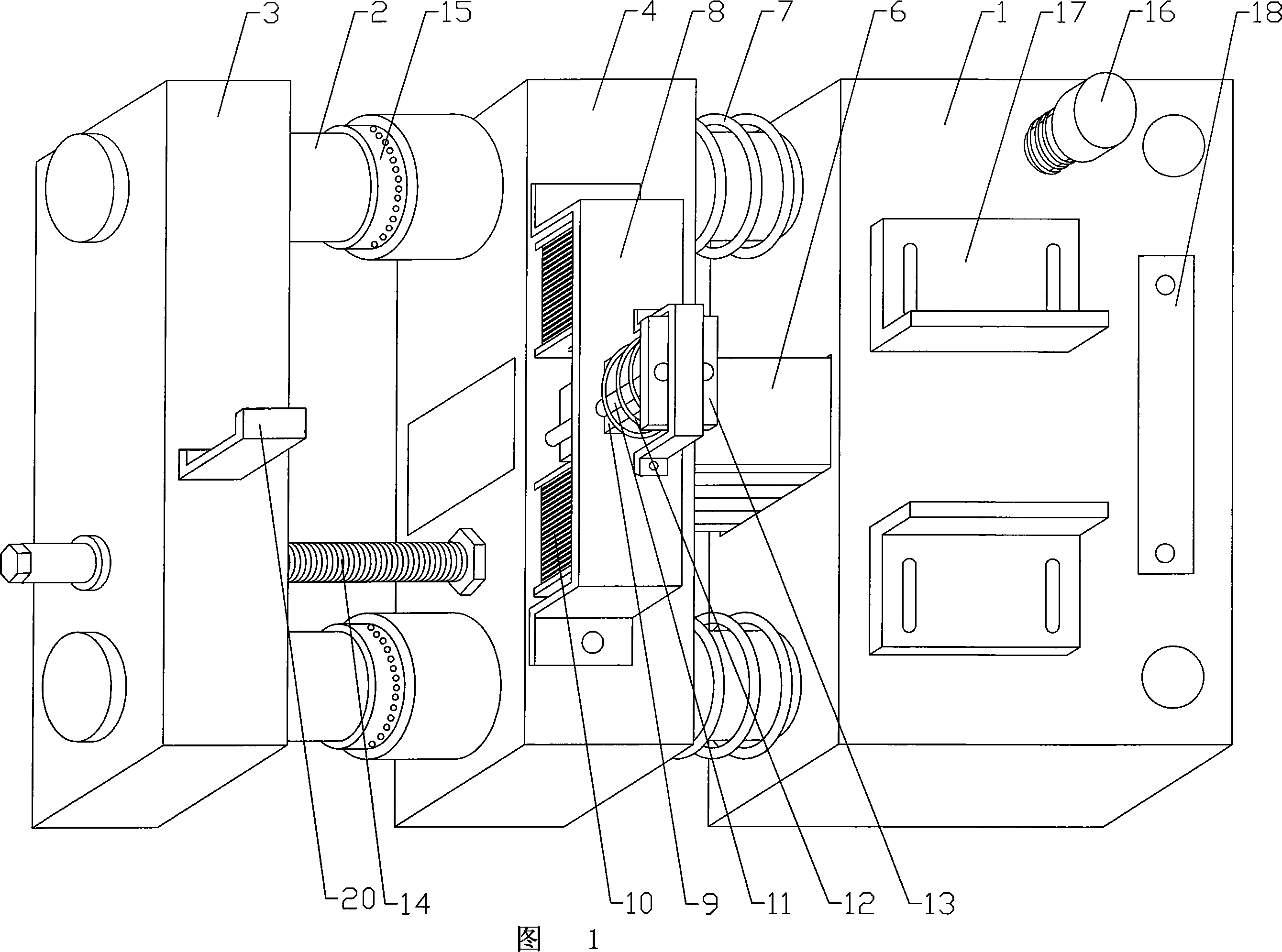

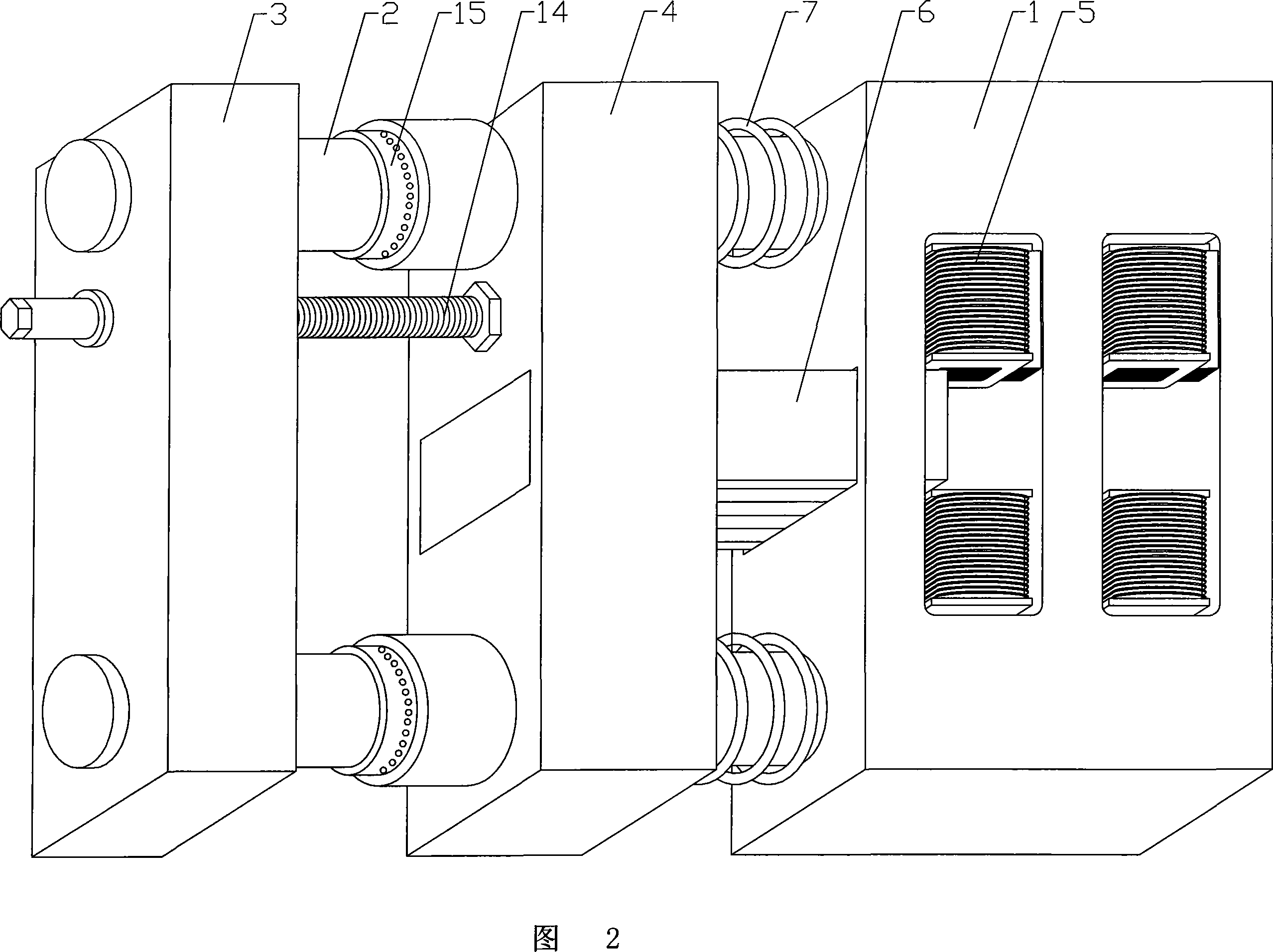

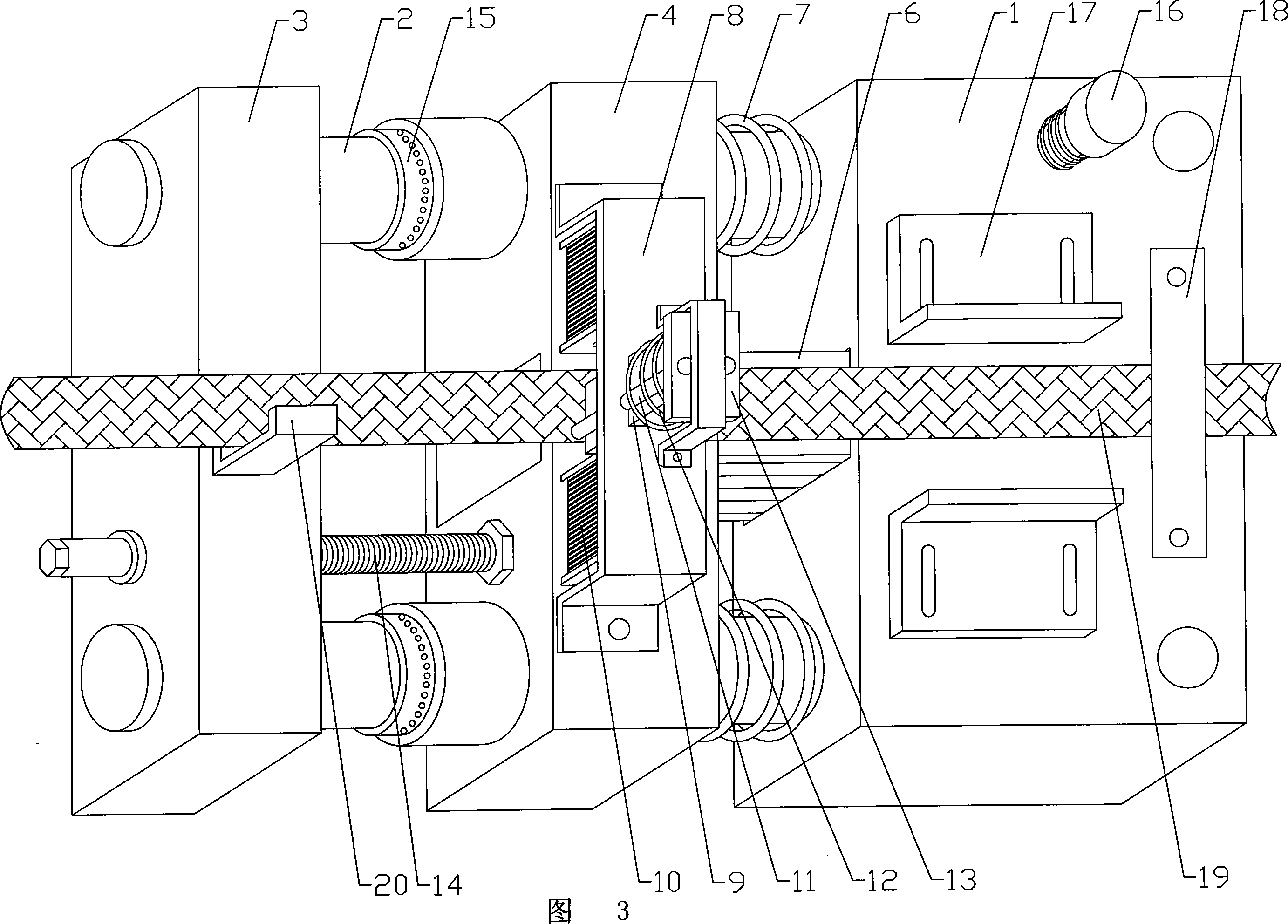

[0020] As shown in Fig. 1, Fig. 2 and Fig. 3: the automatic feeding device of this embodiment includes: a fixed seat 1 fixed on the punch press, one end of the guide rail 2 is connected with the fixed seat, and the other end is fixed on the guide rail frame 3, and the slider 4 A pressing assembly is installed on the top, and the control mechanism controls the slider 4 to move on the guide rail 2. The fixed seat 1 is provided with an electromagnetic coil 5, and the slider 4 is provided with a driving block 6 made of a magnetically conductive material. The control mechanism controls the power on and off of the electromagnetic coil 5, and the driving block 6 drives the slider 4 under the action of the electromagnetic coil. Moving on the guide rail 2, the slider is provided with a return spring 7.

[0021] The pressing assembly includes: a pressing bracket 8 fixed on the slider 4, a pressing electromagnetic coil 10 is arranged on both sides of the pressing slider 9, and the pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com