Chemical and mechanical grinding bench chemical liquid supplying device

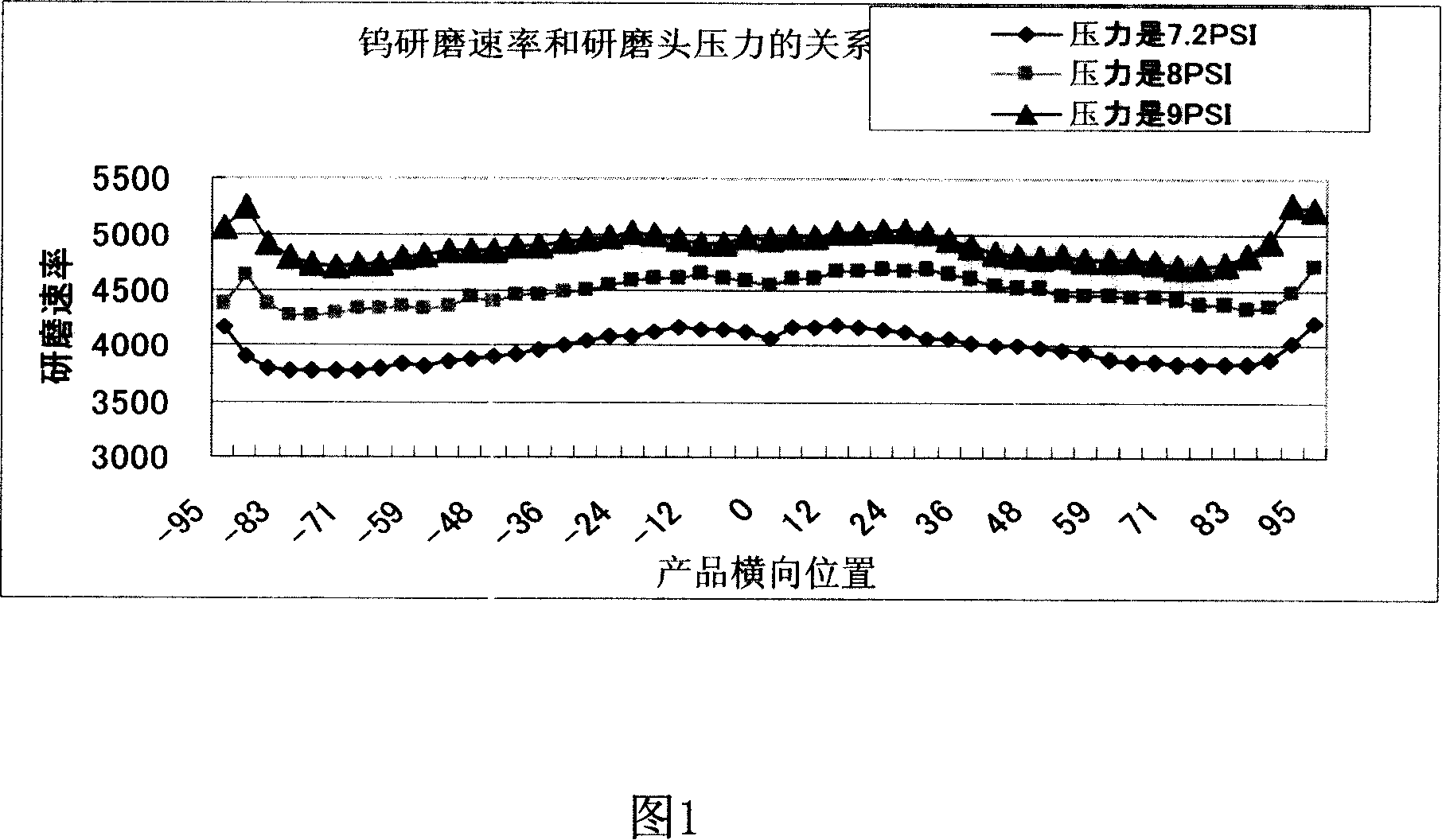

A grinding machine and chemical mechanical technology, which is applied to surface polishing machine tools, grinding/polishing equipment, electrical components, etc., can solve the problems of poor grinding effect, low speed of three curves, and inconspicuous effect, etc., to improve the flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

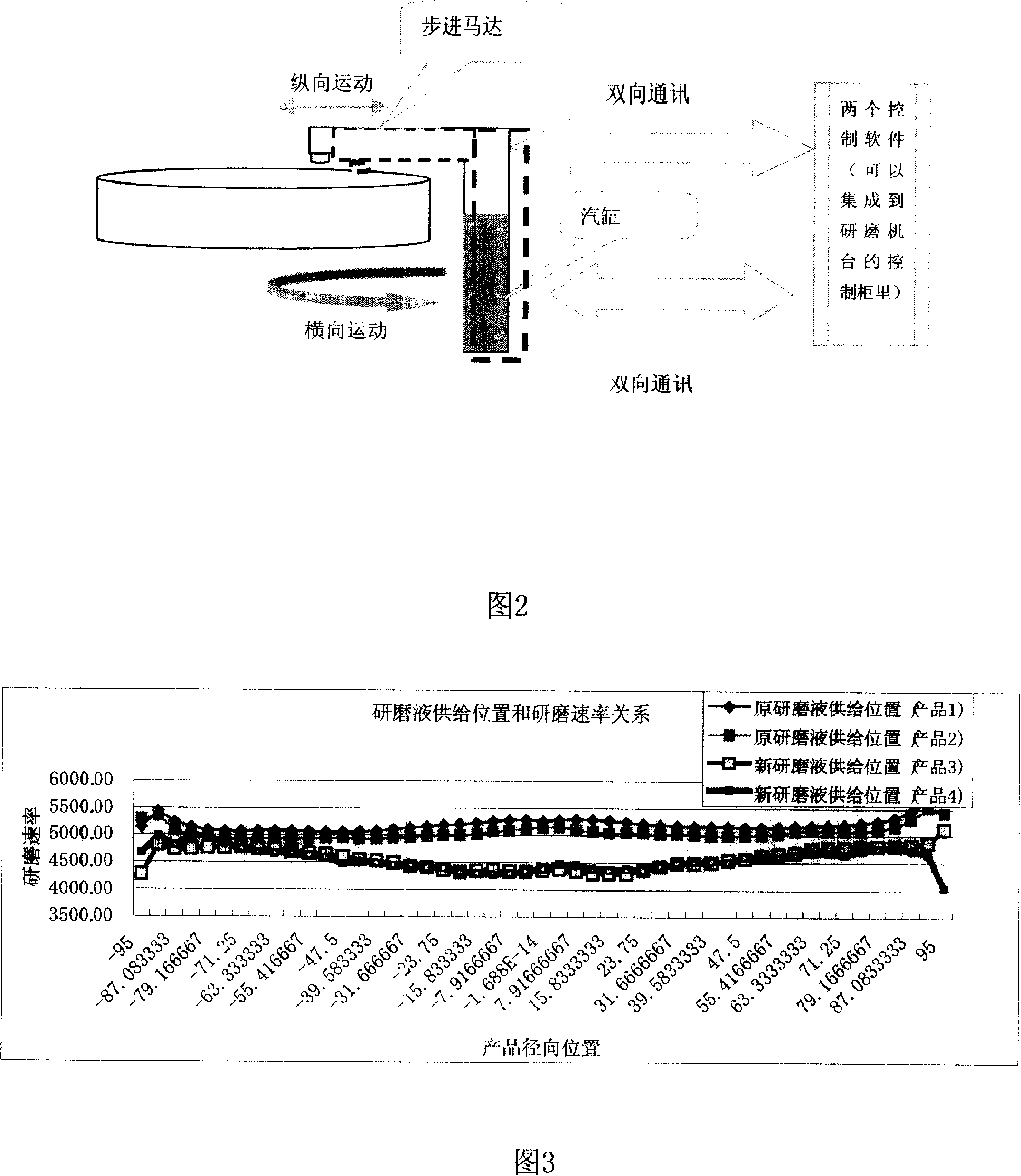

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0011] As mentioned above, in the existing grinding process, the position of the nozzle is fixed during the grinding process. In the present invention, some control software units and a series of cylinders and stepping motors are added to change the position of the nozzle during the grinding process. Location.

[0012] As shown in Figure 2, in order to achieve better control of the surface uniformity of the product in the present invention, for the grinding liquid supply device of the grinding machine, a cylinder is added to the hardware to control the lateral movement of the supply arm, and a stepping motor is added to Control the longitudinal movement of the supply arm; the newly added cylinder is connected to the supply arm through the transmission shaft. When the cylinder extends, it pushes the supply arm to move inward and latera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com