Cutter wheel for cutting glass

A cutter wheel and glass technology, applied in glass cutting devices, glass production, glass manufacturing equipment, etc., can solve problems such as damage to glass breaking strength and yield reduction, achieve ease of folding and cutting process, promote the growth of cracks, improve The effect of segmentation process yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

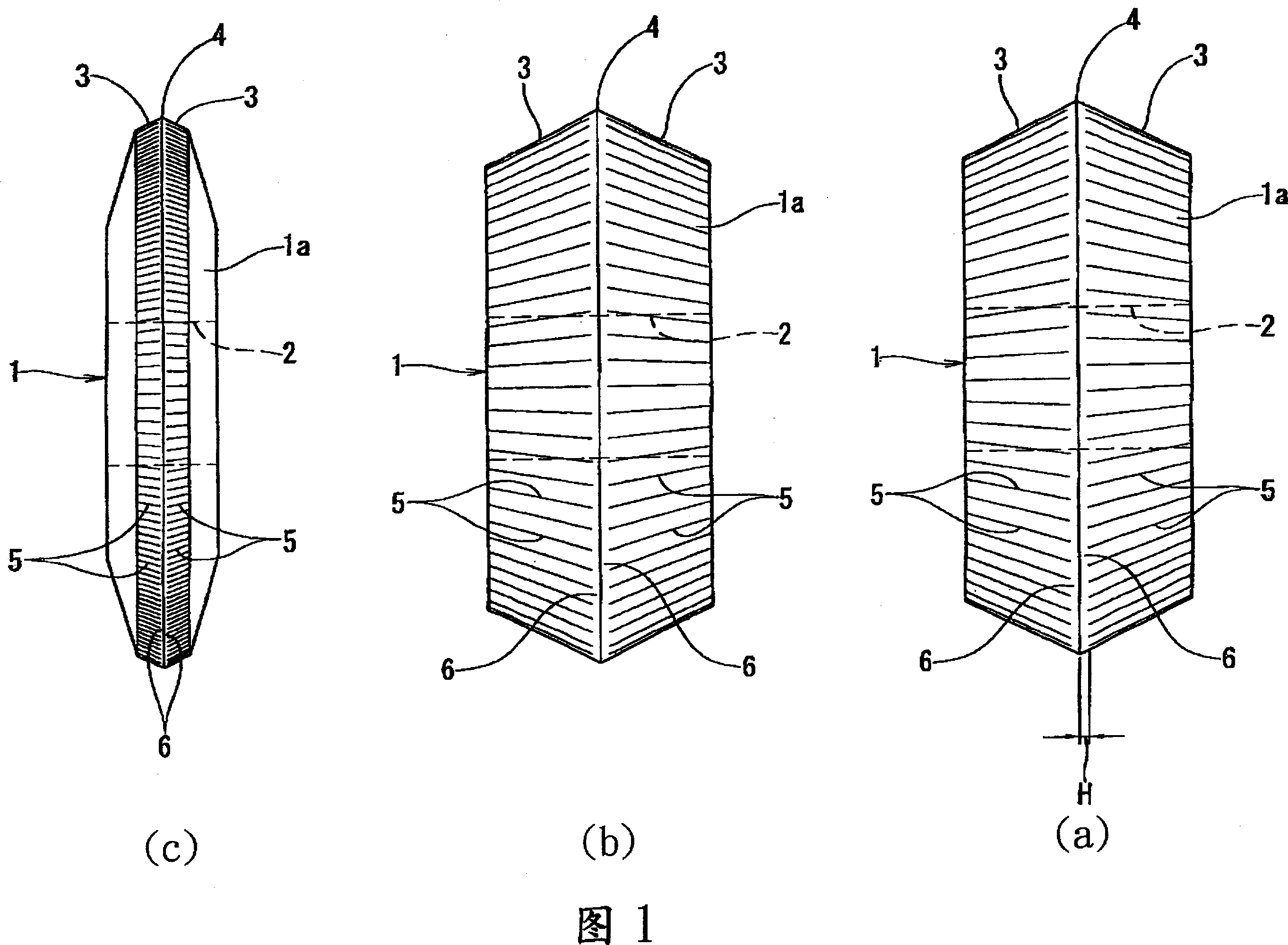

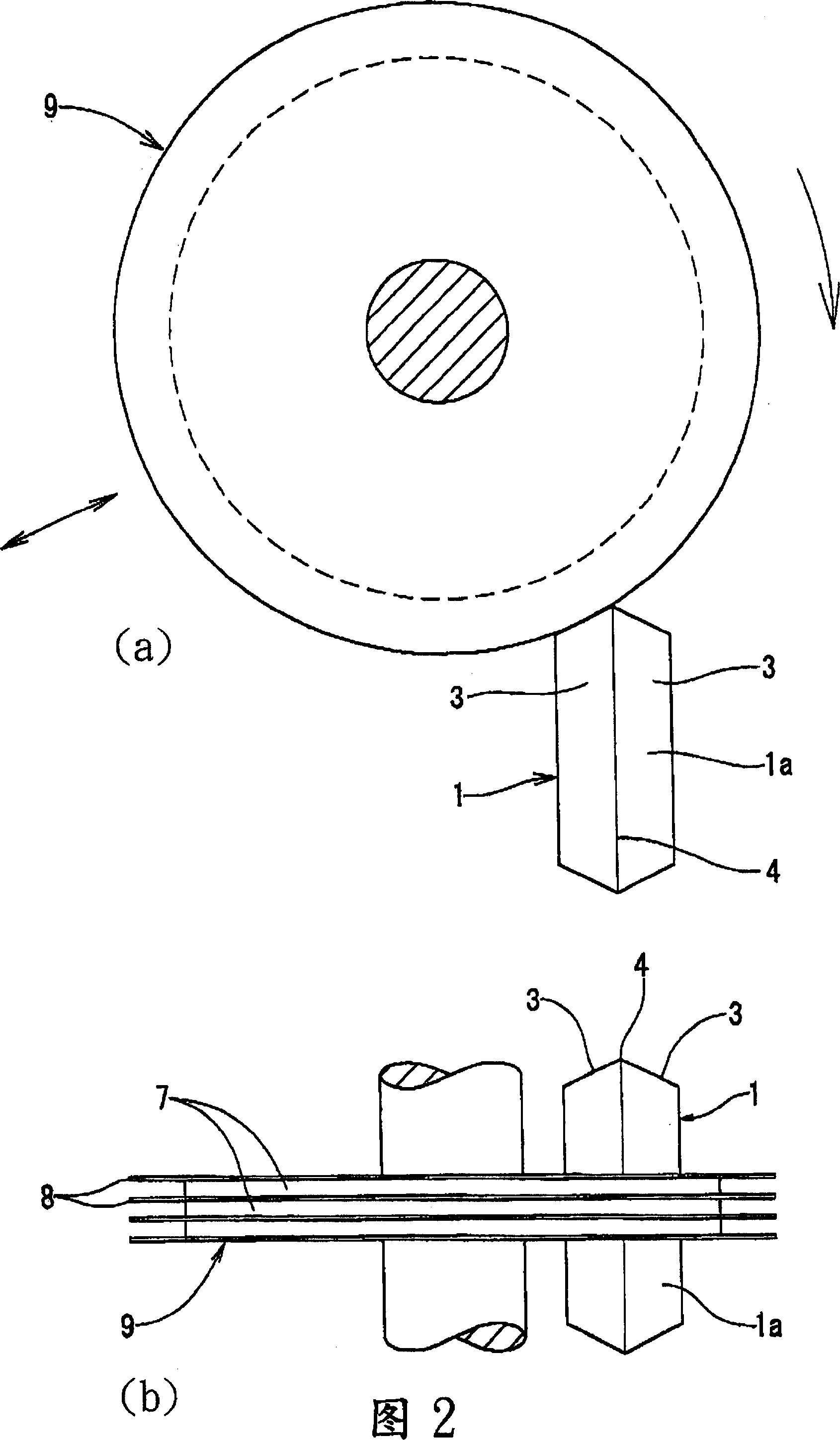

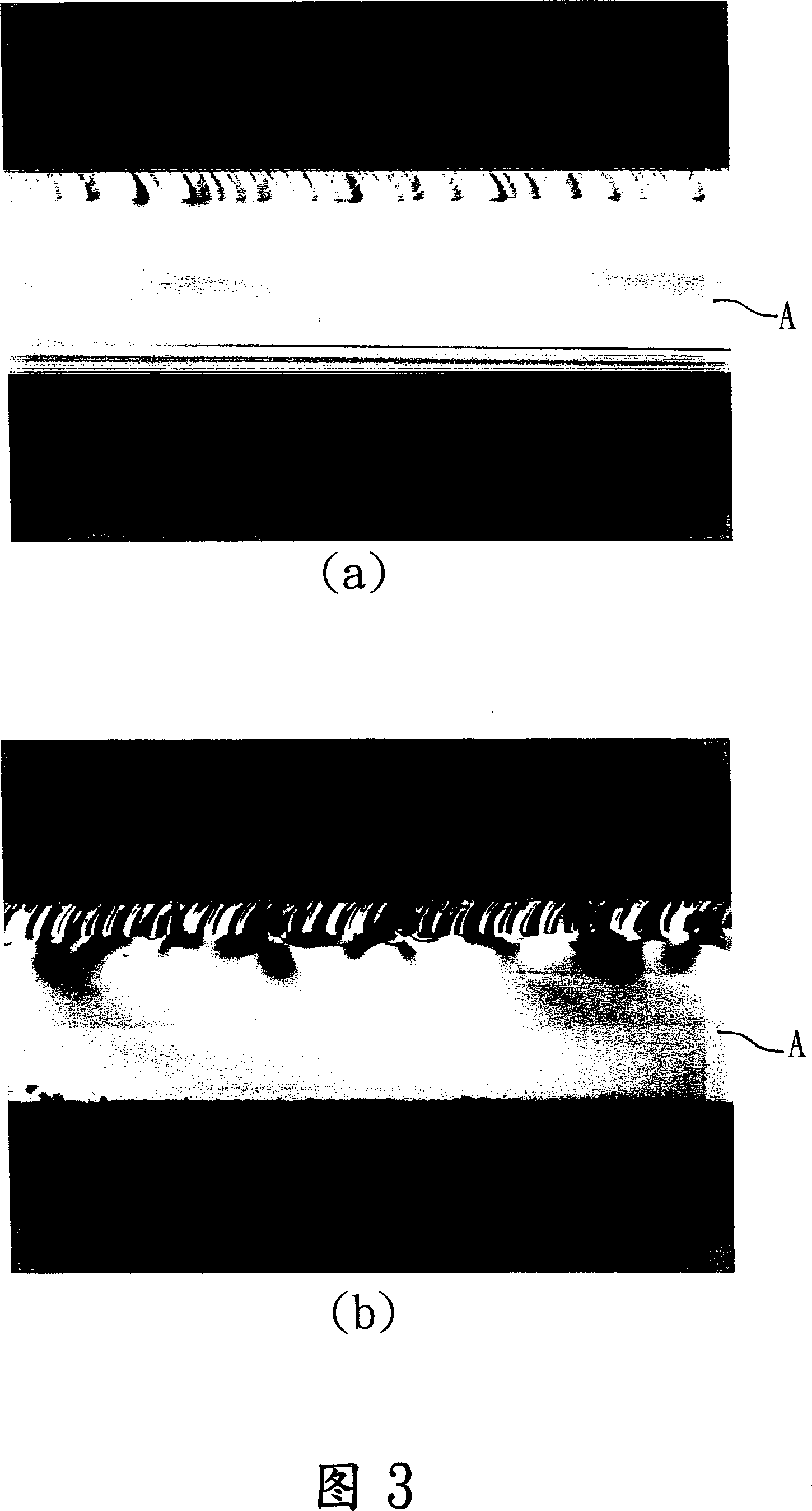

[0032] Next, embodiments of the present invention will be described together with illustrated examples.

[0033] As shown in FIG. 1 , the structure of the cutter wheel 1 for glass cutting is that, on both sides of the outer periphery of the disc-shaped wheel body 1a with the shaft hole 2 penetrating along the shaft center, there are provided with inverted blades extending from the central part in the width direction to the side surface. The inclined inclined surface 3 forms an annular knife-edge ridgeline 4 by the intersecting portion of the two inclined surfaces 3 . On the above-mentioned two inclined surfaces 3 , grinding grains 5 are attached at intervals from the knife-edge ridgeline 4 .

[0034] As the material of the above-mentioned wheel body 1a, any one of diamond sintered body and cemented carbide can be used. Incidentally, the size of the wheel body 1a is set such that the maximum outer diameter is 2 mm to 6 mm, and the thickness in the axial direction is 0.3 mm to 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com