Discharge type display device

A technology for display devices and discharge electrodes, which is applied to discharge tubes, AC plasma display panels, gas-filled discharge tubes, etc., can solve the problems of rising circuit costs and insufficient solutions, and achieve the goals of reducing burdens, improving luminous efficiency, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

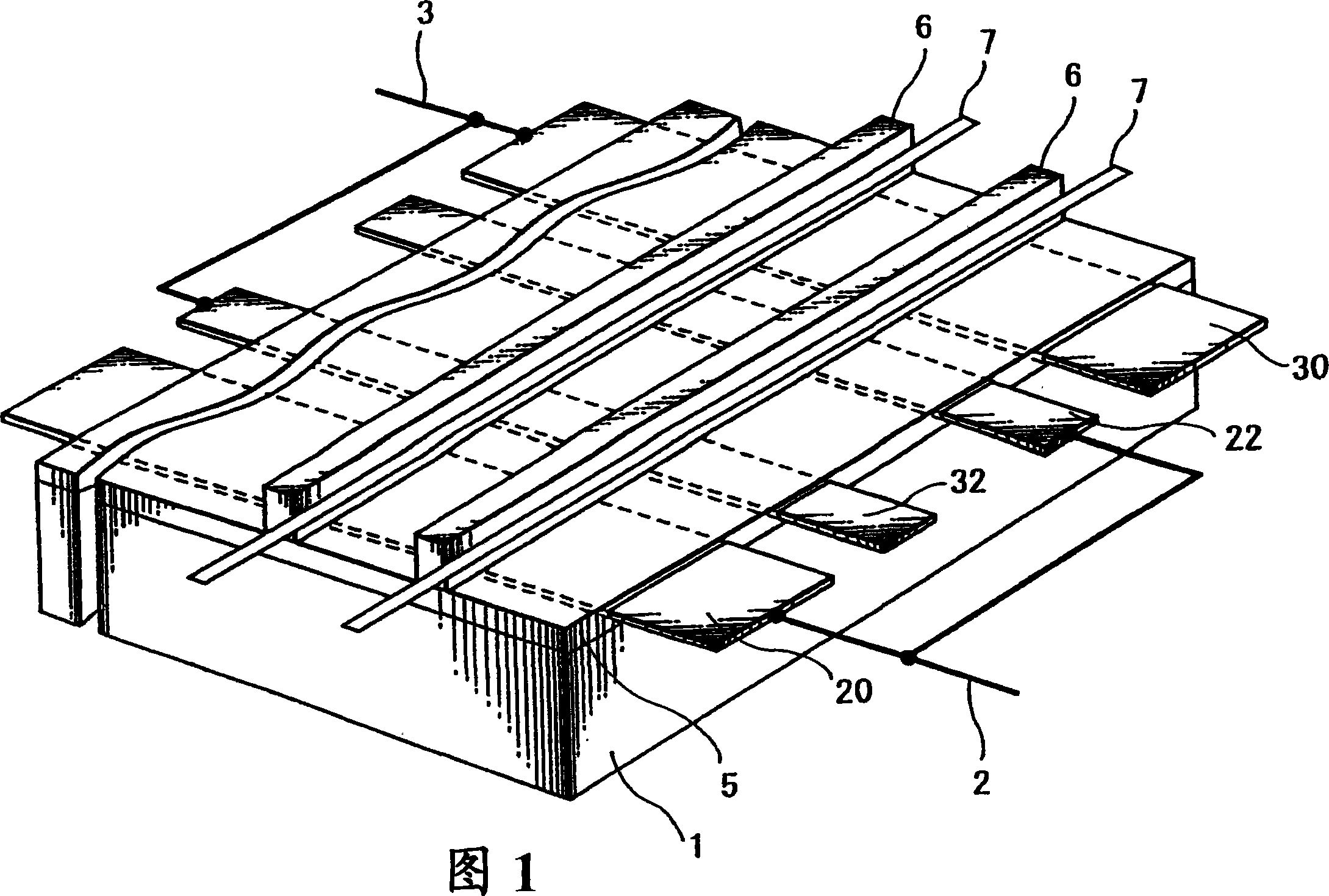

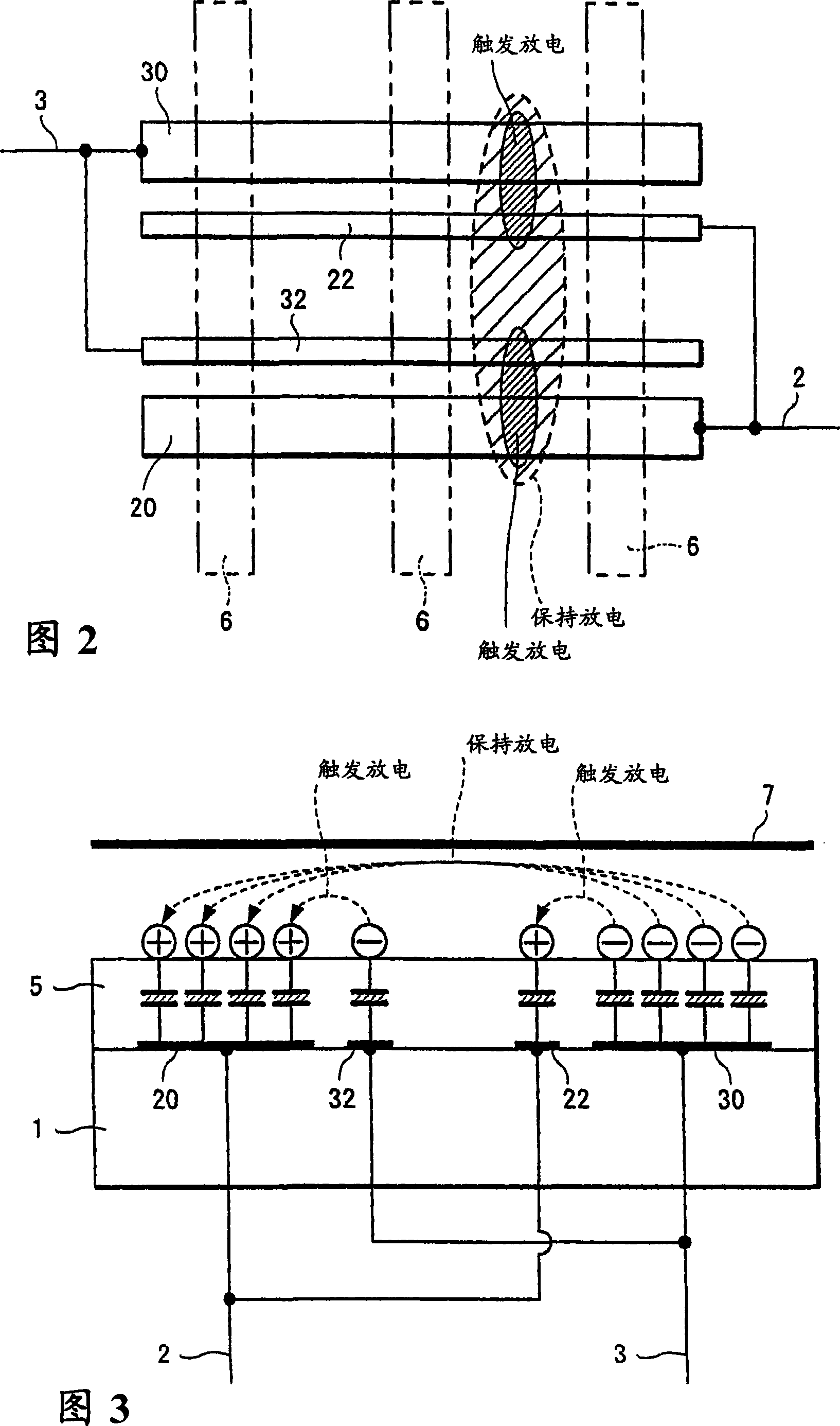

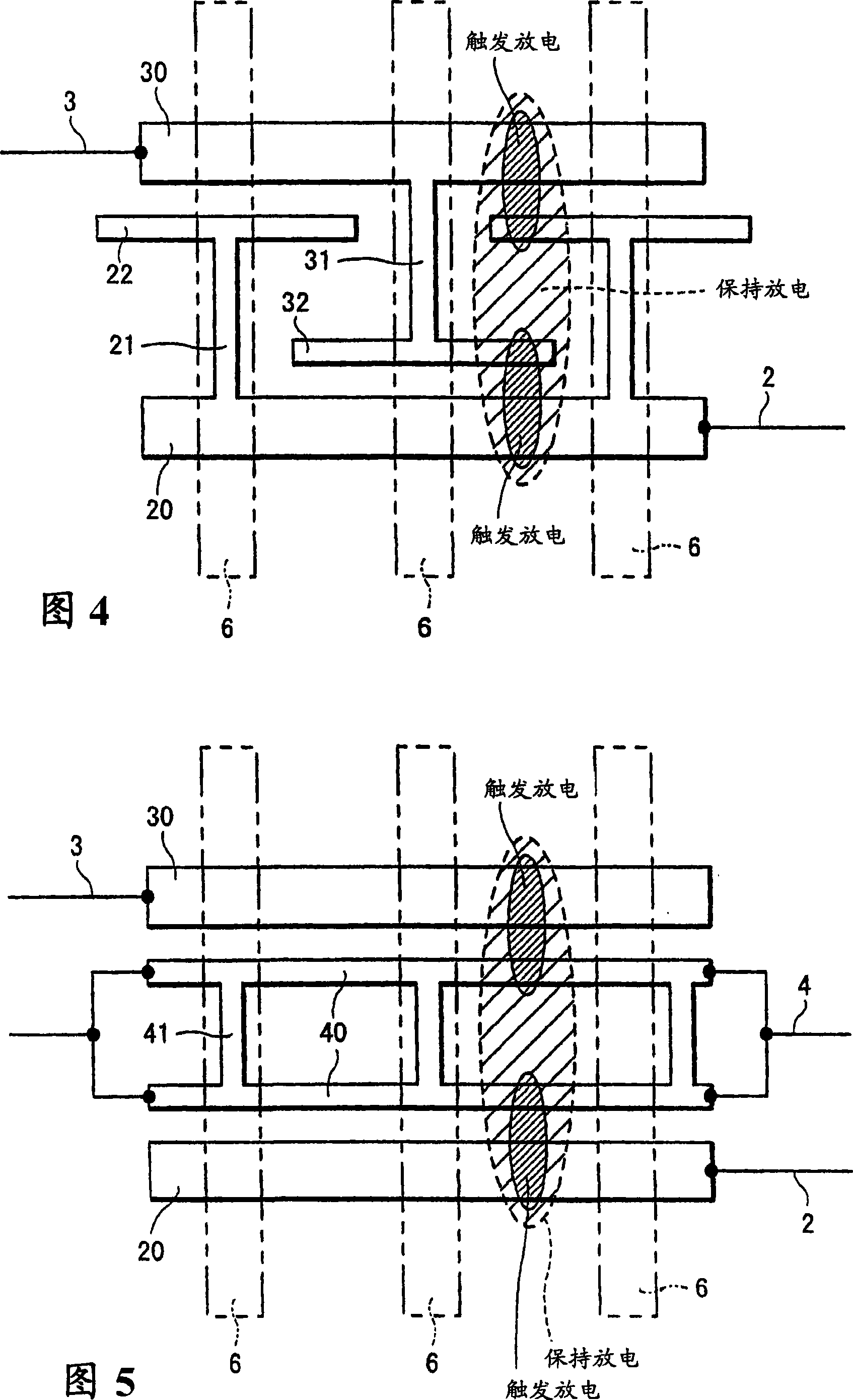

[0051] One embodiment of the first invention will be described using the developed perspective view in FIG. 1 , the electrode structure explanatory view in FIG. 2 , and the operation explanatory sectional view in FIG. 3 .

[0052] First of all, these electrodes are not limited to the combination of transparent electrodes such as ITO and Ag or Cr, Cu, Ni, etc. bus electrodes for improving conductivity used in common PDPs, and may also be opaque electrode materials. Of course, This forming substrate may be provided on the front side or on the back side.

[0053] The main discharge electrodes, that is, the sustaining electrodes 20 and 30 are covered with the dielectric layer 5 and a dielectric layer such as MgO (not shown) that has excellent secondary electron emission and good resistance to ion bombardment. Therefore, the electrodes 20 and 30 themselves may also serve as bus electrodes and discharge electrodes.

[0054] Auxiliary discharge electrodes, that is, trigger electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com