Condensation tube drainage device

A technology of condensing tubes and liquid containers, which is applied to the types of heat exchangers, indirect heat exchangers, fixed conduit components, etc., and can solve the problem of increased liquid film in the lower row of condensing tubes, increased volume of heat exchange equipment, and decreased heat exchange performance, etc. problem, to achieve the effect of reducing the thickness of the liquid film, simple installation, and reducing drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

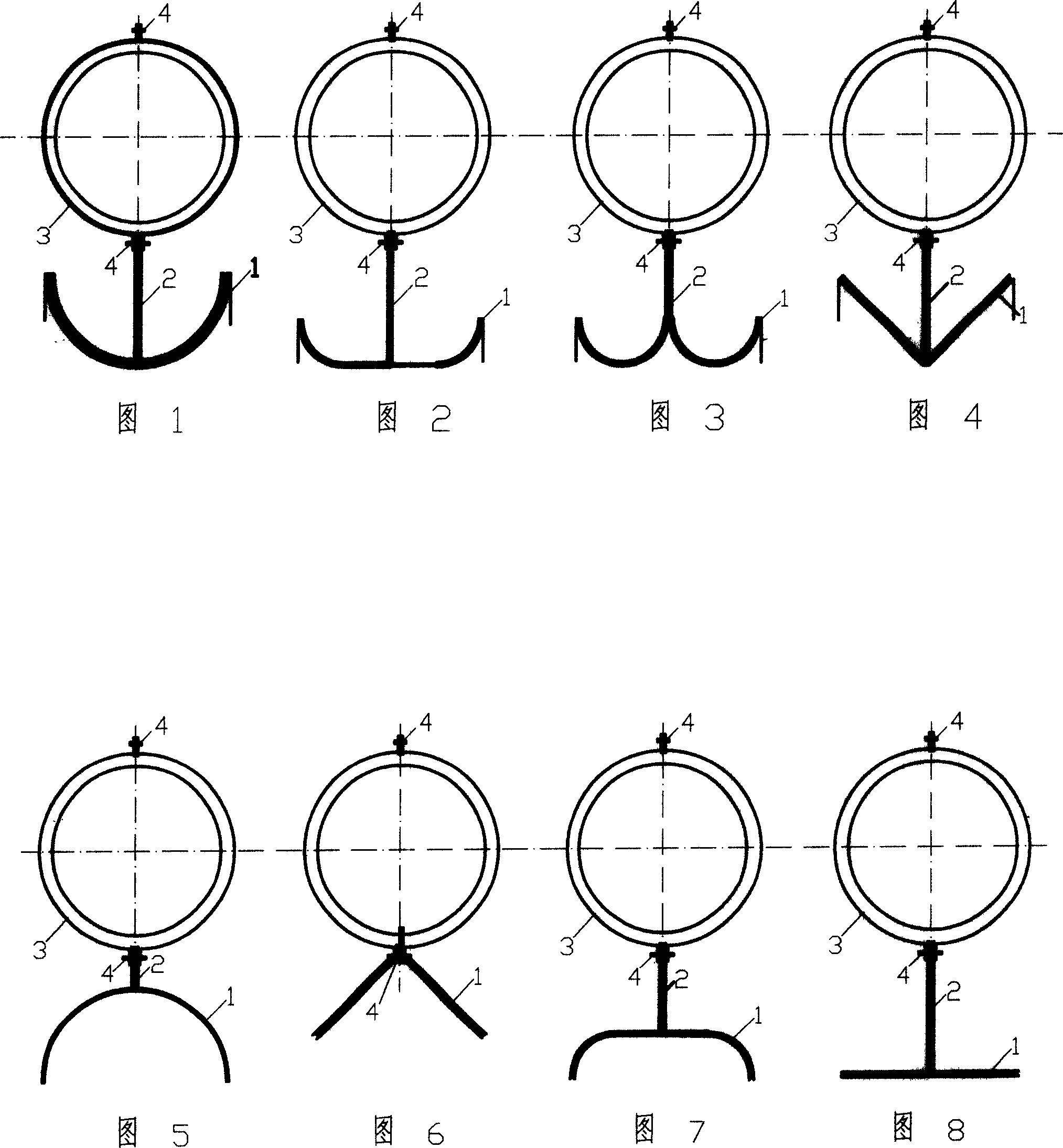

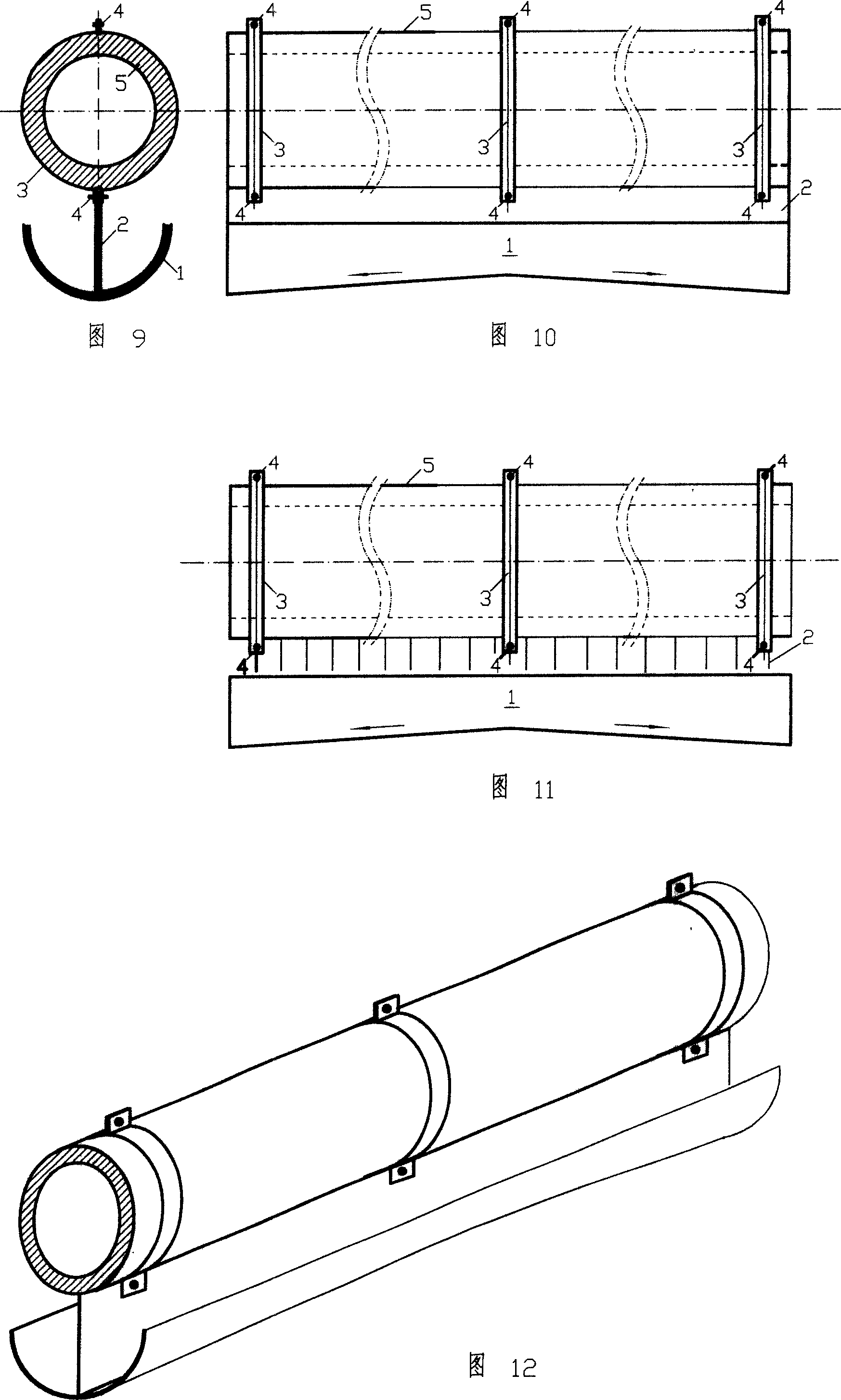

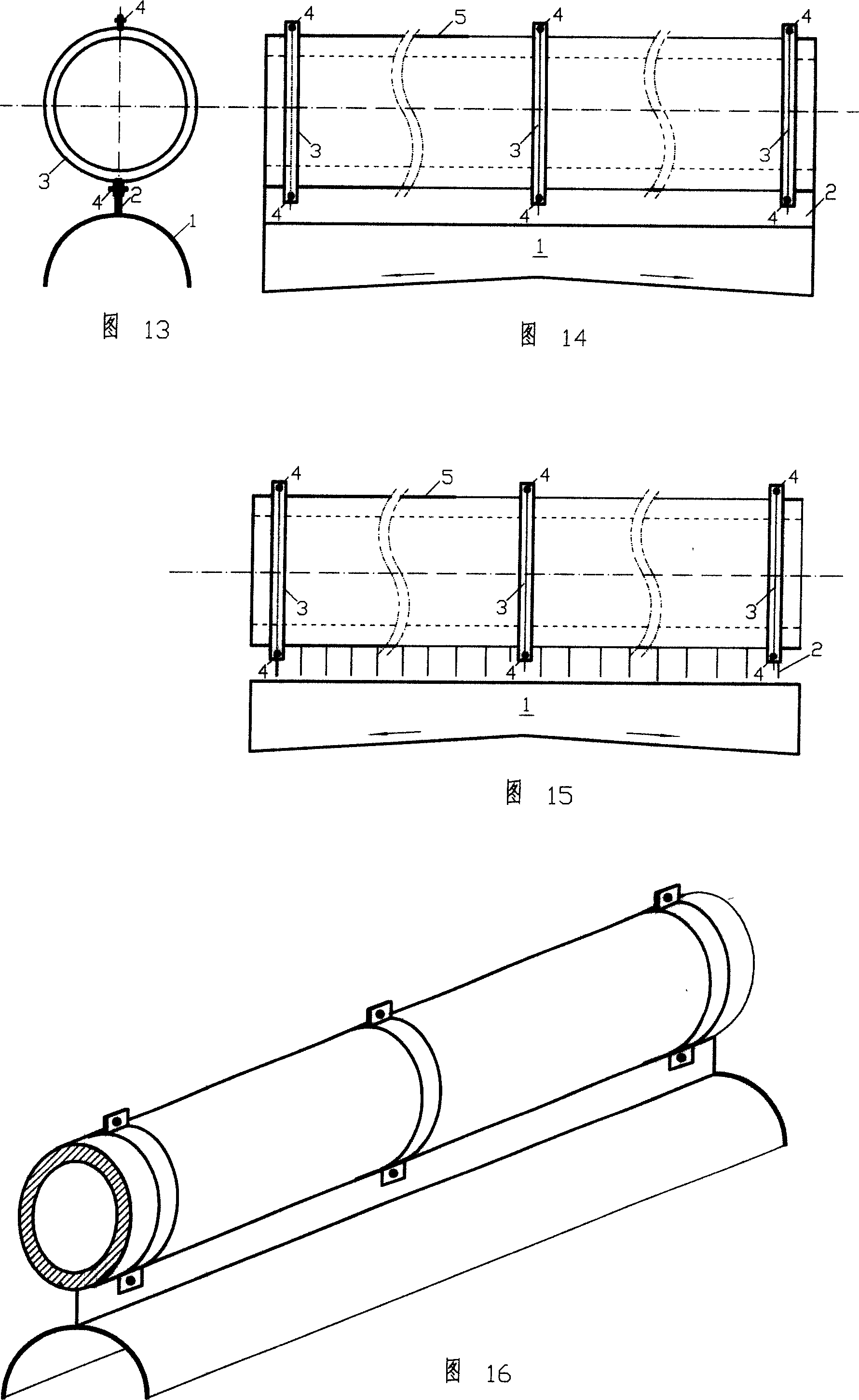

[0041] Condenser liquid guide, the composition includes: liquid guide tank 1, the upper part of the curved surface liquid guide tank 1 has a flat continuous drainage plate 2, and the liquid guide tank 1 and the described drainage plate 2 pass through the retaining spring 3 and the pin 4 Fixed on the condenser tube 5. The connection and arrangement modes in the drawings can be selected as required.

Embodiment 2

[0043] In the above-mentioned condensation pipe liquid guide, the cross-sectional shape of the liquid guide groove 1 is a curved surface, such as single arc, double arc, ellipse, etc., which can enhance heat transfer while conducting flow. In order to reduce the processing cost and adapt to different tube spacing and fluid guide volume, it can also be made into a flat plate, such as a single flat plate or a double flat plate. Liquid guide. The connection and arrangement modes in the drawings can be selected as required.

[0044] Example 2

[0045] In the above-mentioned condensation tube liquid guide, the shape of the diversion plate 2 can be a simple plane or a continuous plate in the form of a curved surface, or it can be made into a zigzag, fin-shaped, or linear grille shape according to the needs of diversion. non-continuous plate.

[0046] When the liquid guide tank used has sufficient liquid space or the distance between the heat exchange tubes is limited, the guide p...

Embodiment 3

[0048] In the above-mentioned condensation tube liquid guide, the connection between the drain plate 2 and the circlip 3 can be connected by a pin 4, or can be connected by welding, riveting, etc.; the fixing between the circlip 3 and the condensing tube 5 The method can be fixed by the pin 4, or can be directly fixed on the condensation pipe 5 by using a steel circlip with greater elasticity and strength. The connection and arrangement modes in the drawings can be selected as required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com