Welding image identification method

A recognition method and image technology, which is applied in the directions of image enhancement, image data processing, character and pattern recognition, etc., can solve the problems of limited application, not making full use of image prior knowledge, and not being able to recognize the shape and outline of the molten pool, so as to achieve applicable sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

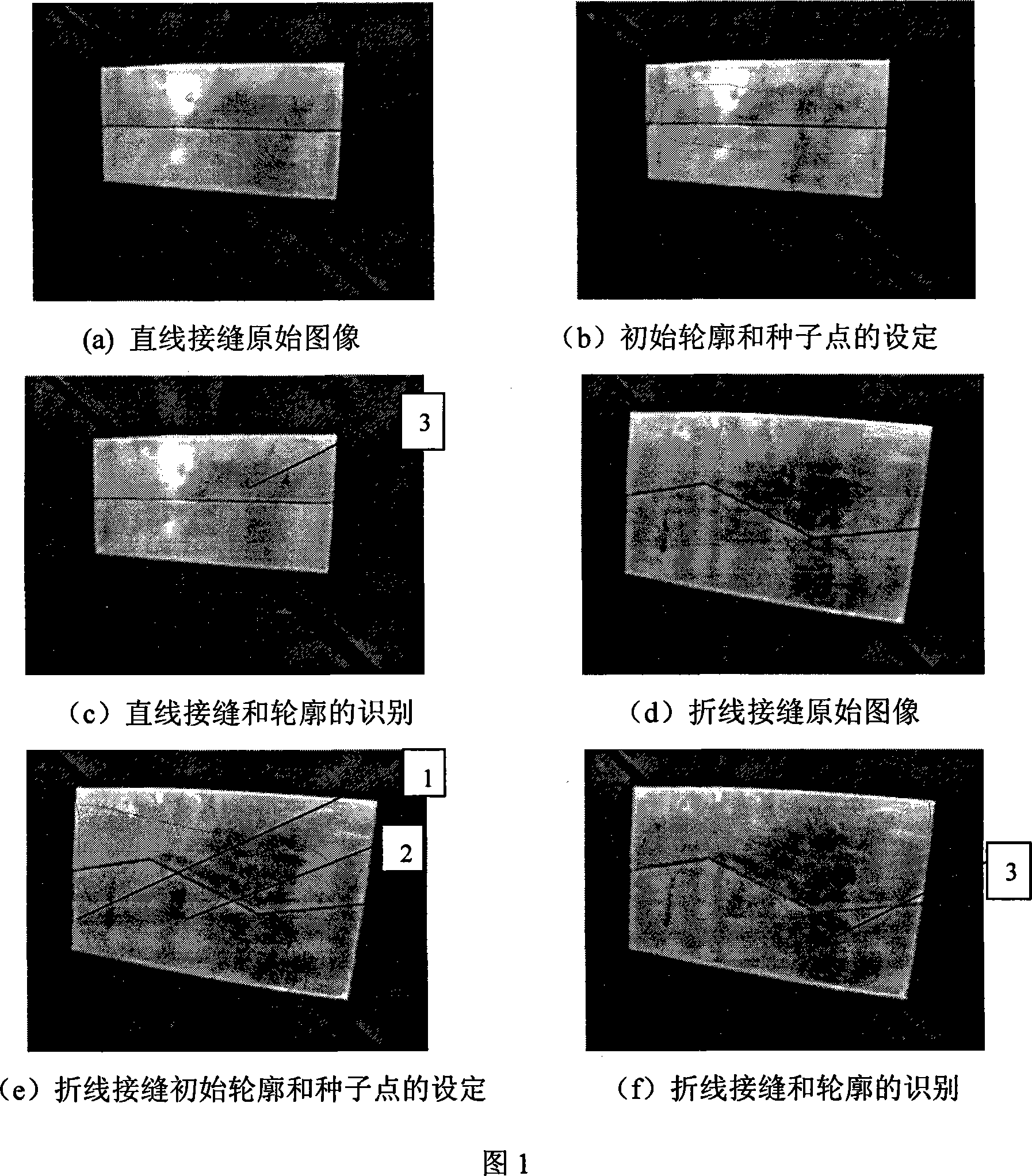

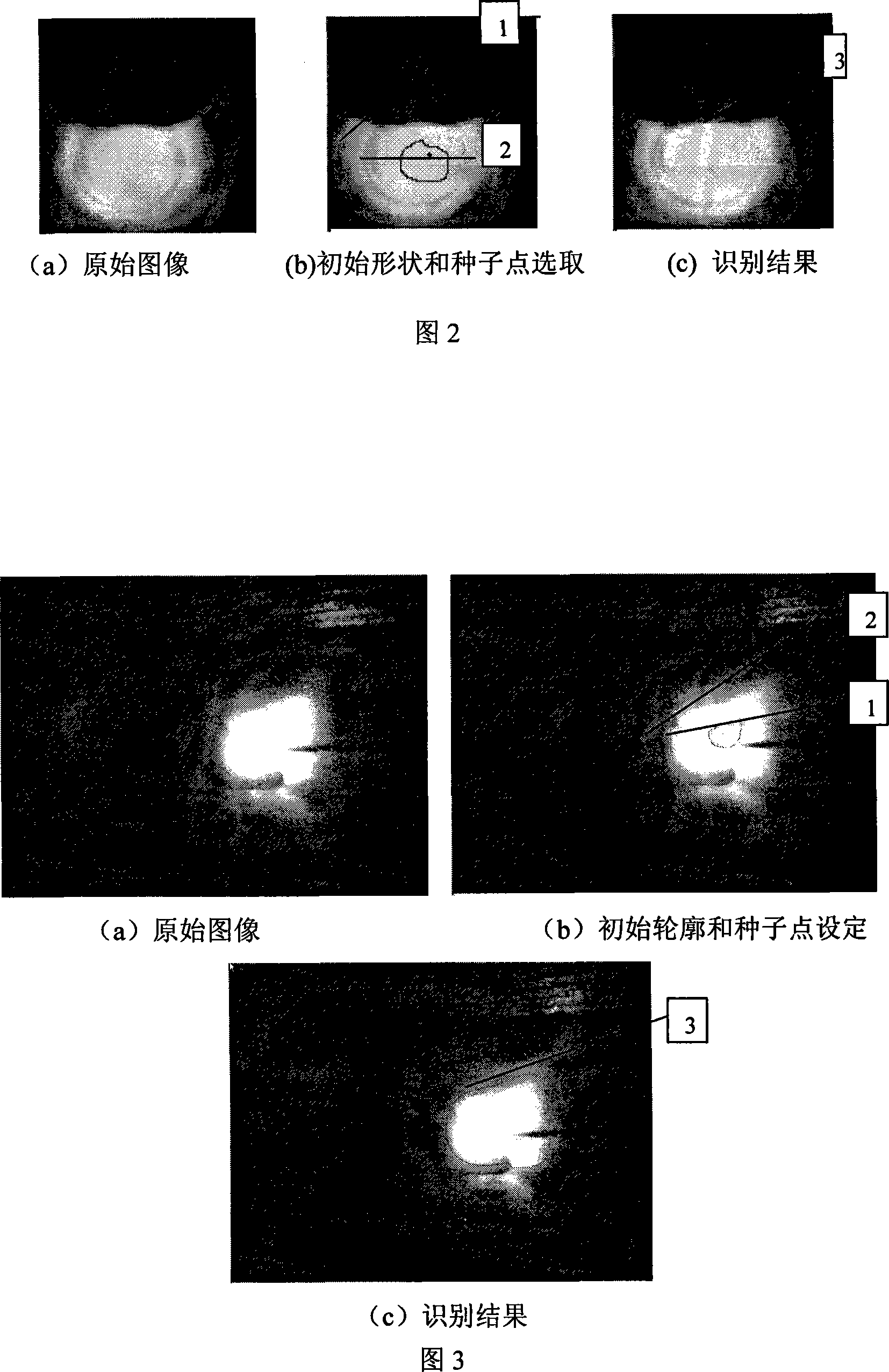

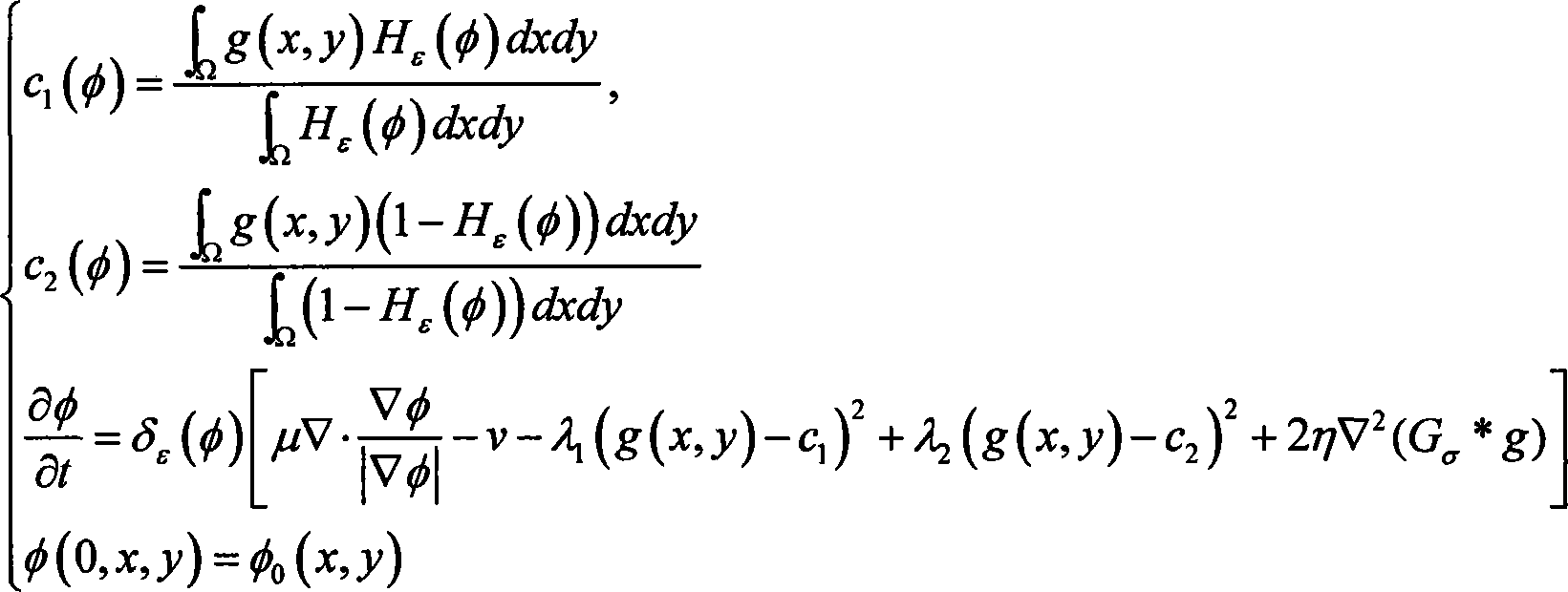

[0041] Step (1): Use the image acquisition card to convert the image of the CCD camera into a digital image. The image of the workpiece before welding is the image of the entire working environment within the field of view of the camera. It is directly collected by the CCD, and the size is 768×576. a), (d) shown. The image of the molten pool is collected according to the different needs in the production. The image of the molten pool during GTAW welding under the two conditions of filling wire and non-filling wire is collected by using a filter with a light transmission range of 590-710nm. No wire filling is used here. The size of the molten pool image during welding is 128×128, and the size of the molten pool image during wire filling welding is 400×300. The collected images are shown in Figure 2(a) and Figure 3(a) respectively. The purpose of designing this test example is to test the adaptability of the algorithm to different environments, different sizes and different sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com