A cooling fan structure for permanent magnetic generator

A permanent magnet generator and cooling fan technology, applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve problems such as poor temperature stability, performance degradation, and reduced motor service life, so as to ensure continuous working reliability, Good air cooling effect and the effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the following, the present invention will be further described in conjunction with the embodiments in the drawings:

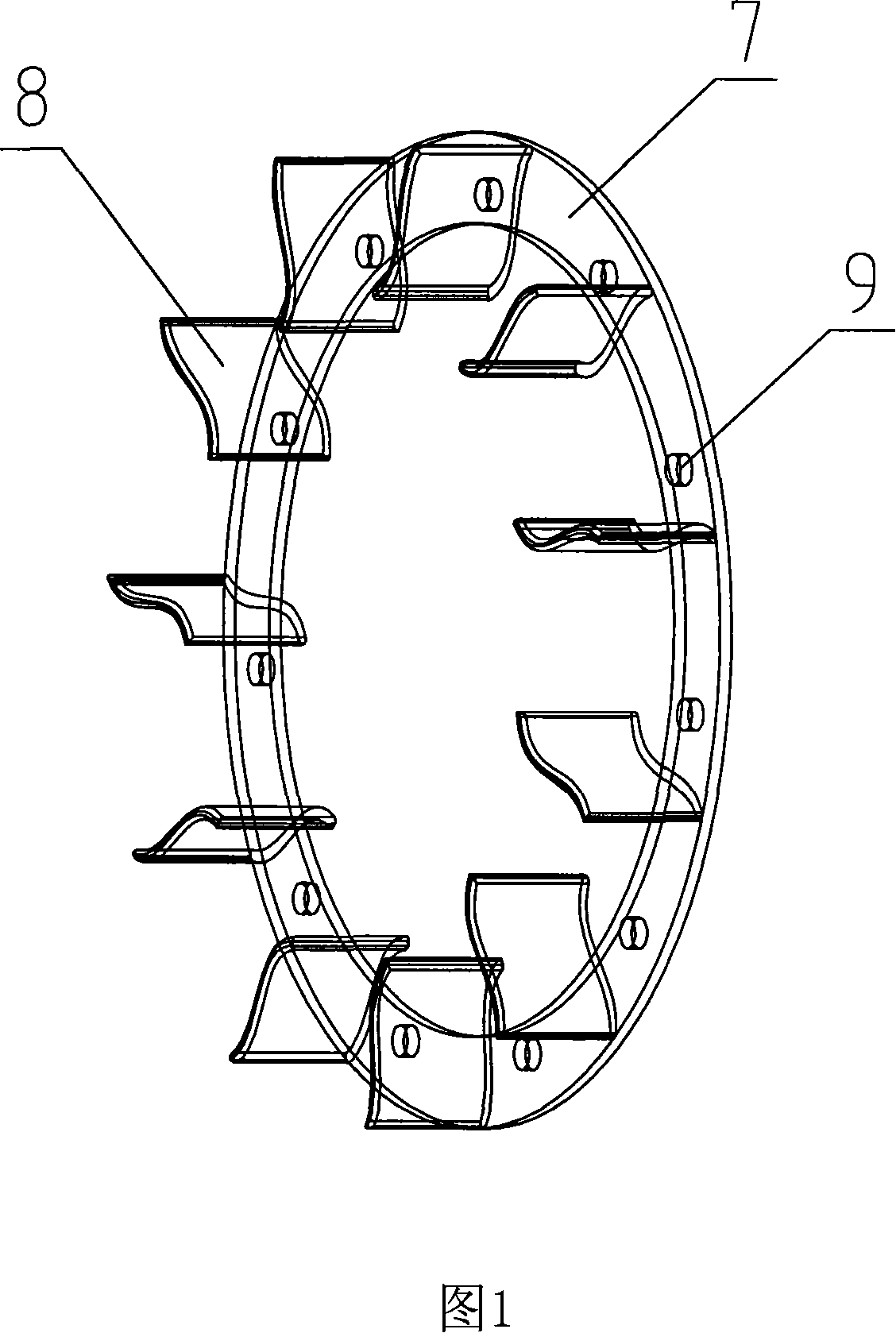

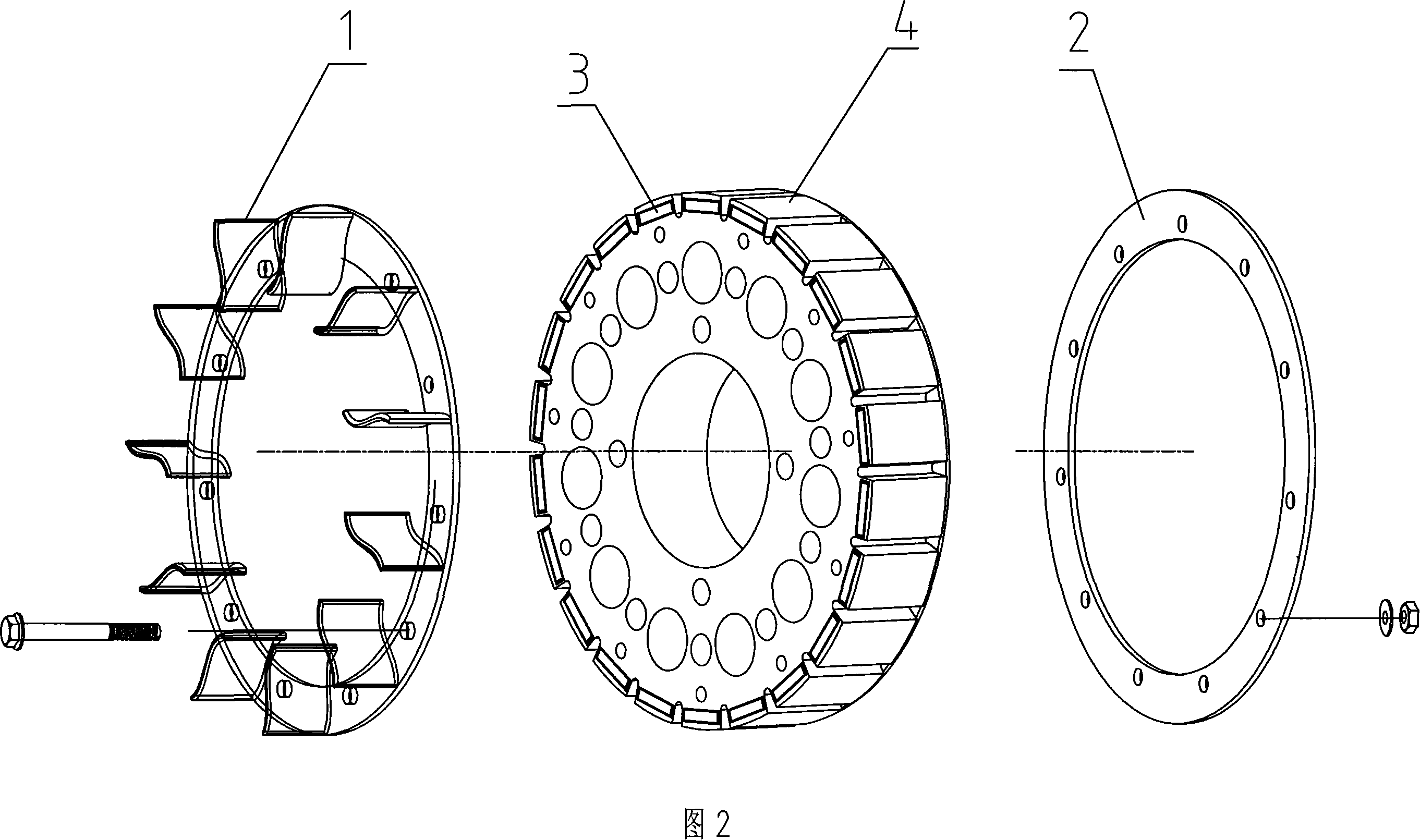

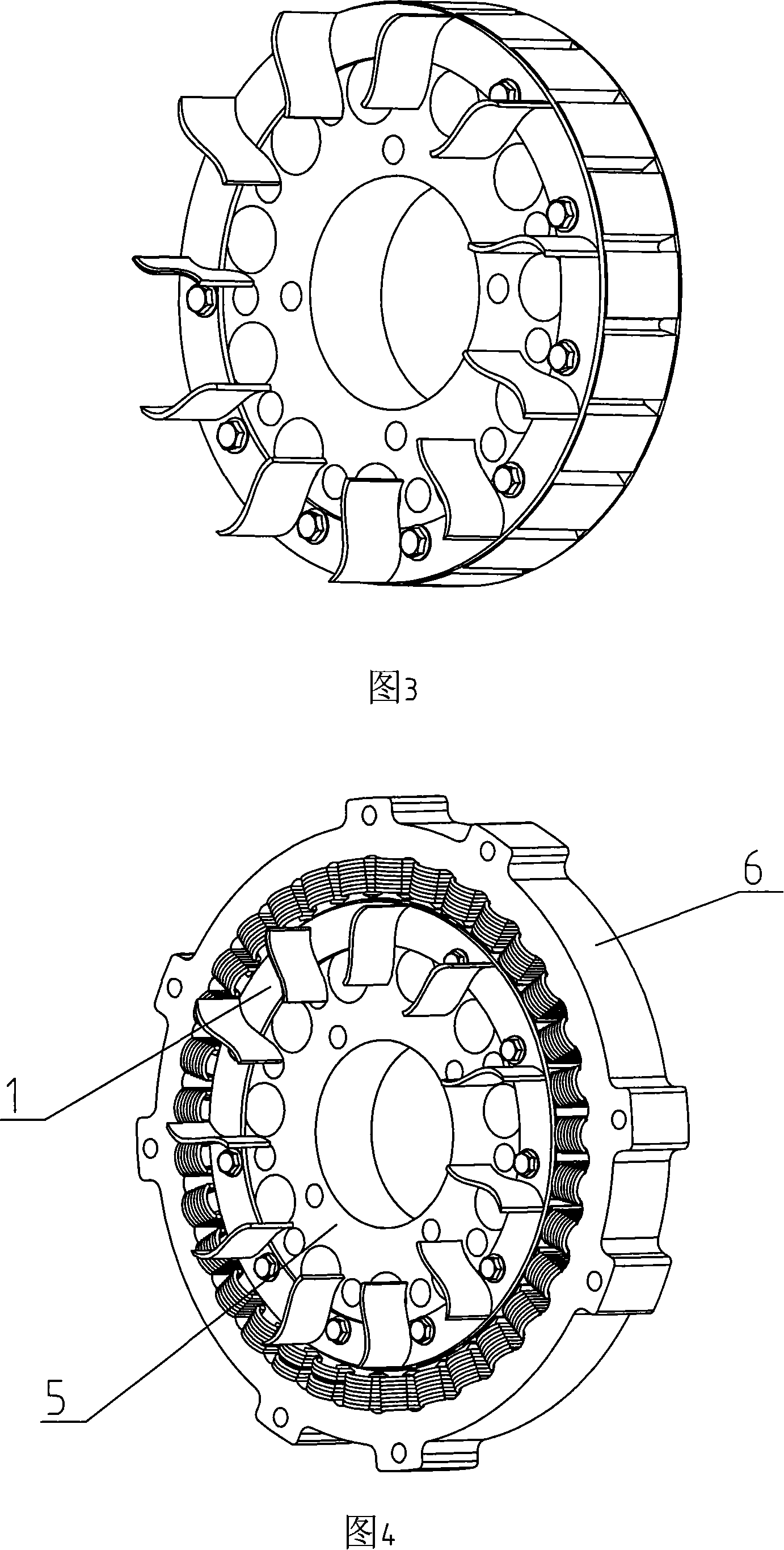

[0019] The present invention is mainly composed of a fan ring 1, a pressing ring 2, a permanent magnet 3, a rotor core 4, a generator rotor 5, a generator stator 6, a bottom plate 7, a fan blade 8 and a mounting hole 9 and so on.

[0020] As shown in Fig. 1 and Fig. 2, the present invention uses ventilation holes on the generator rotor 5. The fan ring 1 and the pressure ring 2 are installed on the generator rotor 5. The fan ring 1 and the pressure ring 2 are connected by bolts. It is connected to the rotor core 4 as a whole, and the permanent magnet 3 is installed on the protective rotor core 4. The fan ring 1 and the rotor core 4 equipped with the permanent magnet 3 are respectively arranged on both sides of the bottom plate 7, and the fan blades 8 on the fan ring The other end connected with the bottom plate 7 can be connected with a circular plate.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com