Method for controlling and operating a production cell, and control device

A production process and component technology, applied in the field of control and operation of production units and control devices, can solve problems such as increased complexity, increased complexity, interference, etc., and achieve great advantages and a sense of ease, simplified structure conversion, and simplified parameterization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

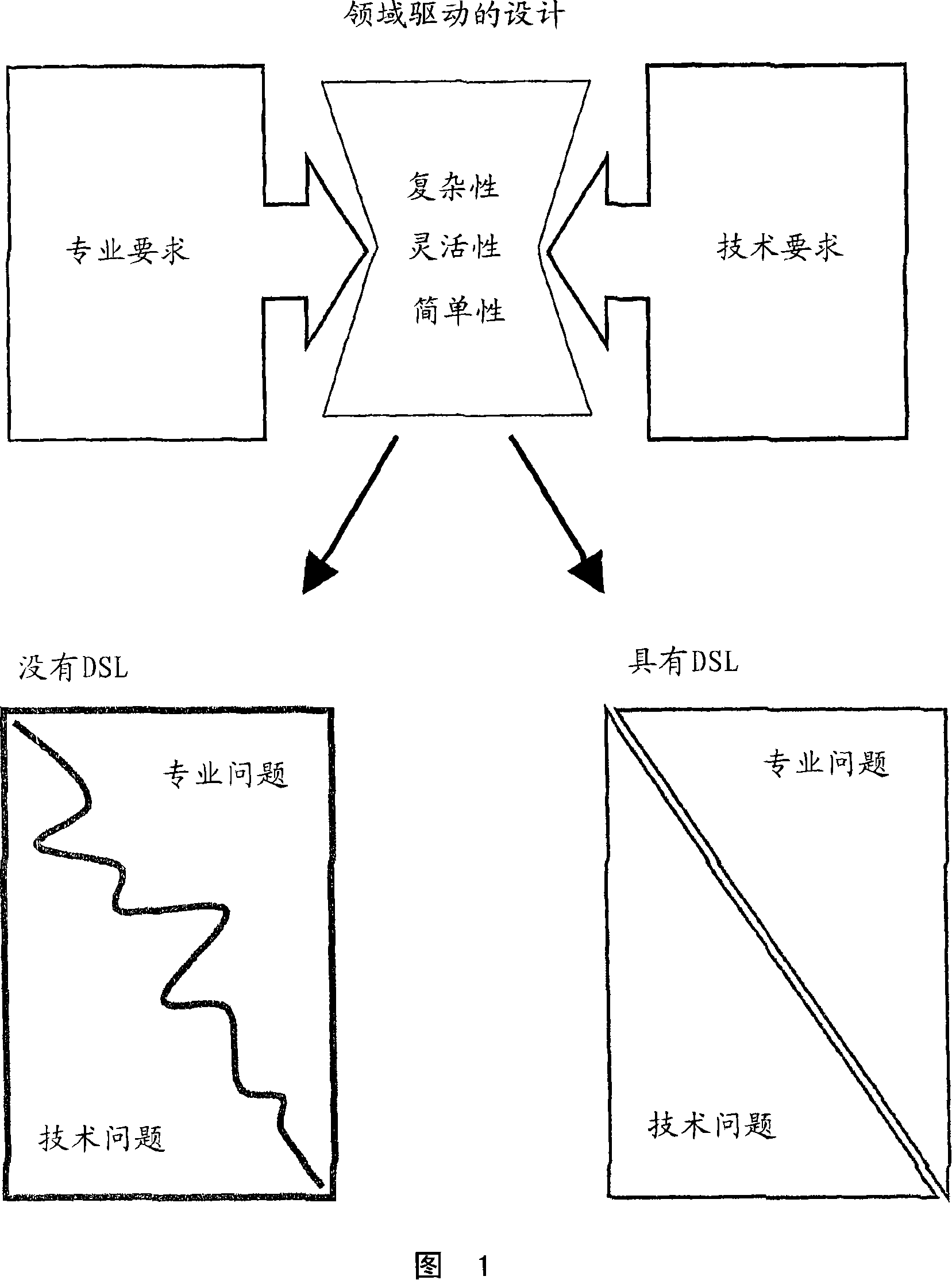

[0152] Refer to Figure 1 below. Current practice points out that in the control software of die-casting machine tools, for example, professional and software-technical problems always arise one after the other. This inevitably leads to increased software complexity. For the transformation of professional and technical requirements, the new solution proposes a consistent separation with the help of Domain Specific Language (DSL) (Figure 1, bottom right). The lower left of Figure 1 shows a domain-driven design without a DSL. The thick lines represent complete mutual coverage of the two problem areas without DSL. The result is not only increased complexity, but especially more work for each program change that is made later on. Domain-driven design based on a domain-specific language offers the great advantage that technical aspects can be treated and resolved separately from professional requirements. This makes professional programming

[0153] - closer to professional iss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com