Power conversion apparatus

A power conversion device and electric power technology, which is applied in the direction of output power conversion device, electrical components, and adjustment of electric variables, etc., can solve the problems of power regulator efficiency reduction, difficulty in miniaturization of the device, and increase in chopper loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0048] Hereinafter, a power conversion device (hereinafter referred to as a power conditioner) according to Embodiment 1 of the present invention will be described with reference to the drawings.

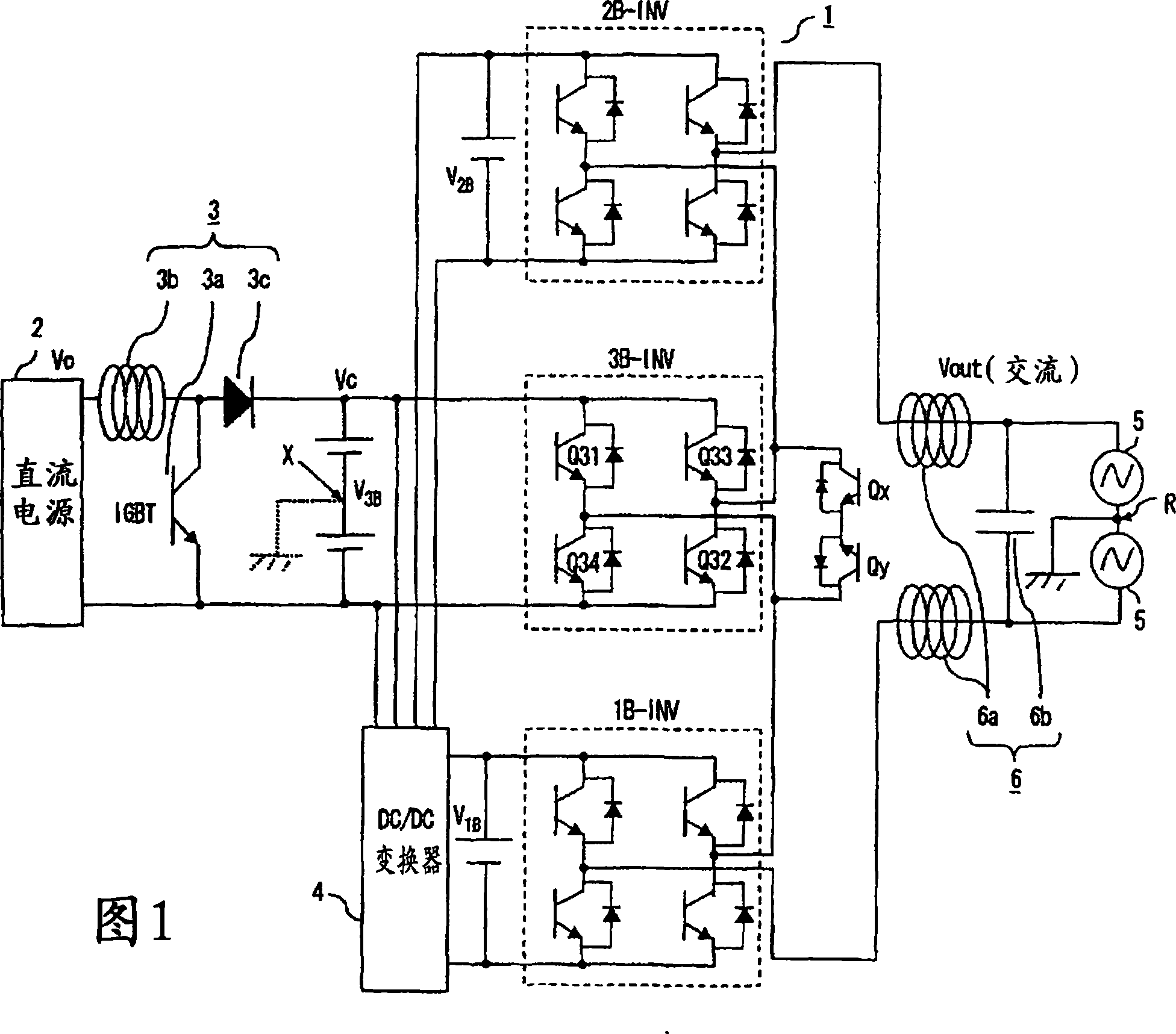

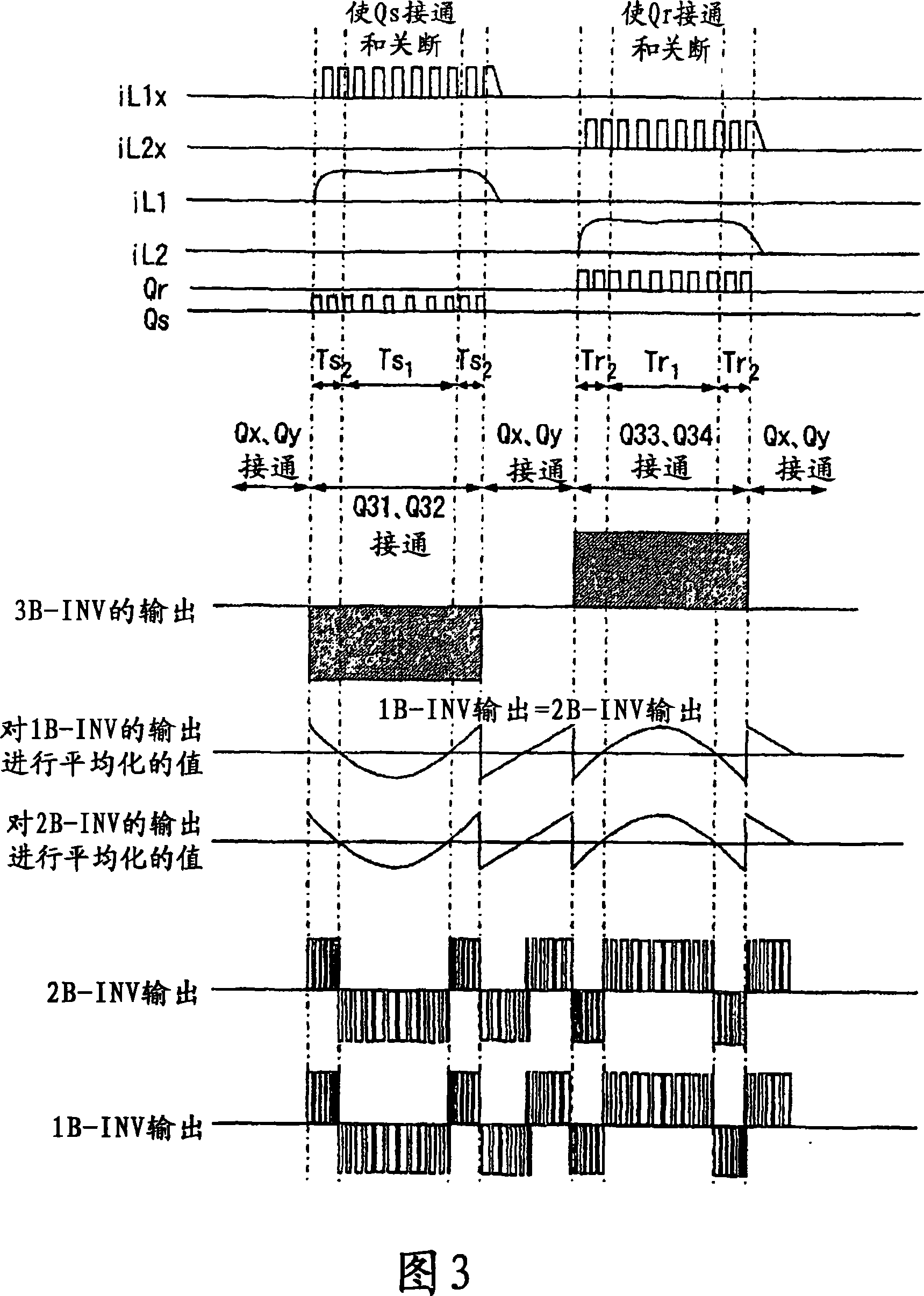

[0049] FIG. 1 is a schematic configuration diagram showing a power conditioner according to Embodiment 1 of the present invention. As shown in Fig. 1, multiple (in this case, three) single-phase inverters 2B-INV, 3B-INV, and 1B-INV are connected in series on the AC side to form an inverter as a single-phase multiple converter. device unit 1. Each of the single-phase inverters 2B-INV, 3B-INV, and 1B-INV is composed of self-arcing semiconductor switching elements such as a plurality of IGBTs connected in antiparallel with diodes. 3B The single-phase inverter 1B-INV is connected to one of two terminals on the AC side of the input single-phase inverter 3B-INV, and the other is connected to the single-phase inverter 2B-INV. In addition, as a short-circuit switch for short-circuiting be...

Embodiment approach 2

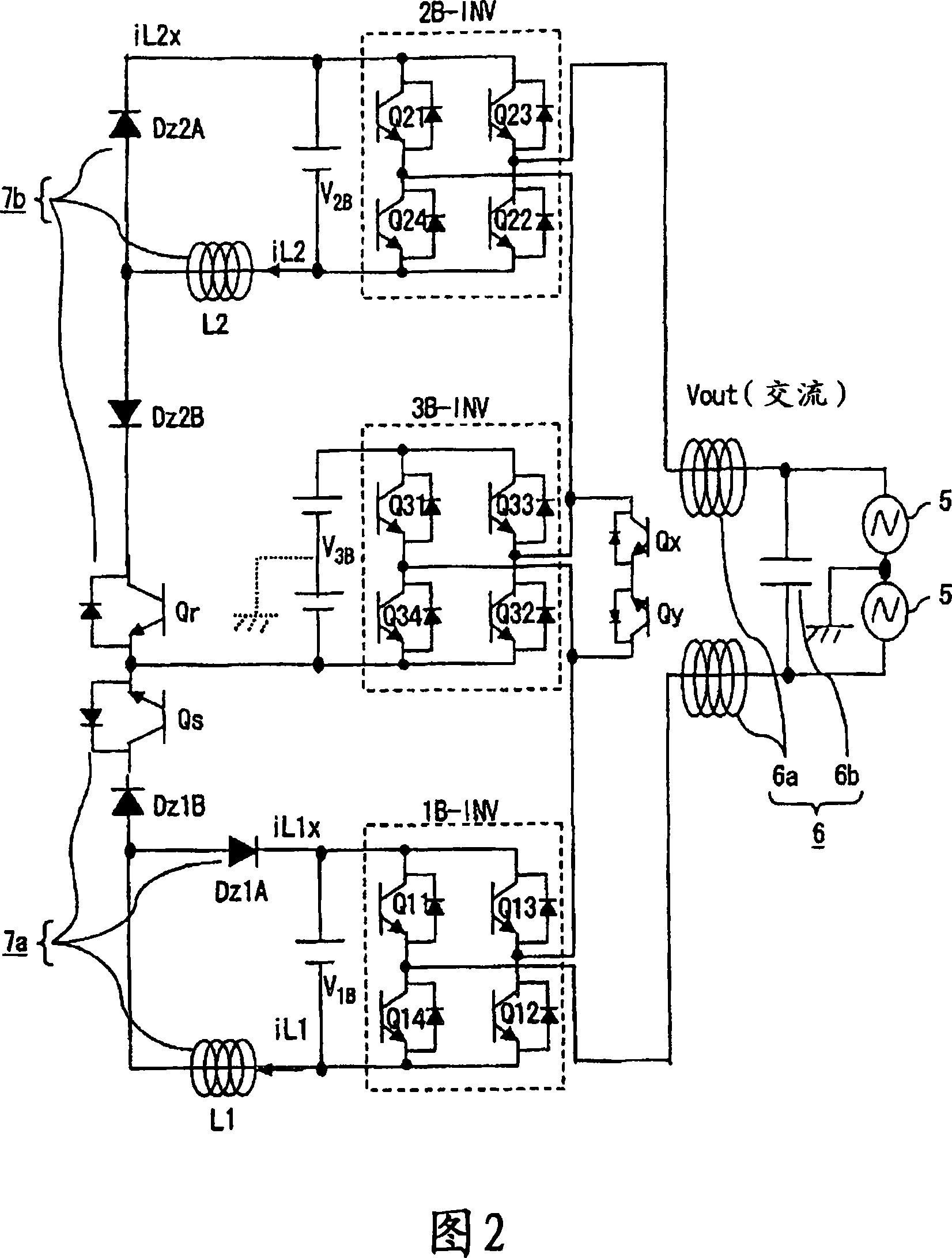

[0068] Next, a power conditioner according to Embodiment 2 of the present invention will be described below with reference to FIG. 4 . As shown in FIG. 4, the DC / DC converter 4 is constituted by chopper circuits 7a, 7b including reactors L1, L2, DC elements Dz1A, Dz2A, and switches Qs, Qr, as in Embodiment 1 above. In this embodiment, the reactors L1 and L2 of the chopper circuits 7 a and 7 b are magnetically coupled by the magnetic coupling core 100 made of a magnetic material.

[0069]In addition, the configuration other than the magnetic coupling of the reactors L1 and L2 is the same as that of the first embodiment described above. In addition, FIG. 4 omits illustration of the DC power supply 2 and the step-up chopper circuit 3 for convenience.

[0070] The operation will be described below.

[0071] As shown in Embodiment 1 above, when the maximum single-phase inverter 3B-INV is a negative voltage output, the switch Qs of the chopper circuit 7a is turned on and off to su...

Embodiment approach 3

[0090] In Embodiments 1 and 2 above, the largest single-phase inverter 3B-INV is placed at the center, and the following shows how the input DC power supply V 1B , V 2B , V 3B The ascending order configuration of the voltage is the case.

[0091] Also in this case, the maximum DC supply V of the maximum single-phase inverter 3B-INV 3B It is to use the step-up chopper circuit 3 to the DC voltage V obtained in the DC power supply 2 based on solar energy as the 3rd DC power supply. O However, in FIG. 8 , for convenience, the DC power supply 2 and the step-up chopper circuit 3 are omitted. The voltage V of the DC power supply is controlled by the DC / DC converter 4 (see FIG. 1 ) so as to have a predetermined voltage ratio. 1B , V 2B , V 3B , here, assuming V 1B :V 2B :V 3B =1:3:9.

[0092]The DC / DC converter 4 is constituted by the chopper circuits 7a and 7b, and the DC power supply V 2B and DC supply V 1B connected between the chopper circuit 7a, at the maximum DC supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com