Multifunctional flat plate ink-jet decorating machine with mobile frame head

An inkjet printing machine, multi-functional technology, applied in printing, typewriter, transfer printing materials, etc., can solve the problems of occupation, etc., and achieve the effect of wide application range, small tension, accurate and reliable media delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

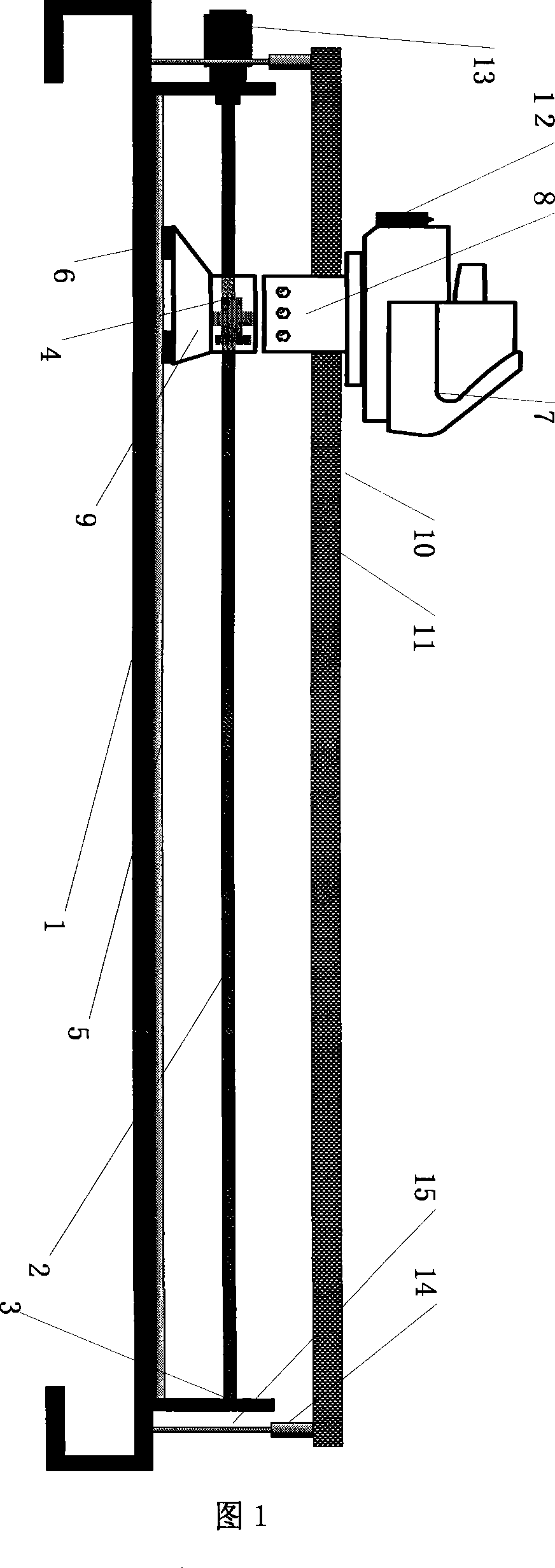

[0010] The structure, working principle and working process of the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0011] As shown in Figure 1, (1) is the frame base, (2) is the ball screw, (3) is the ball screw bearing seat, (4) is the ball screw moving nut, (5) is the linear guide, (6) is the linear guide slider, (7) is the head assembly, (8) is the head support beam, (9) is the head connecting beam, (10) is the printing plate, (11) is the plate bracket, ( 12) is a double set of ink cartridges, (13) is a servo motor, (14) is a double-headed screw, and (15) is a height-adjusting strut. The overall structure is as follows: the machine head assembly (7) is closely connected with and supported by the machine head support beam (8), the machine head support beam (8) is then fixed with the machine head connecting beam (9), and the machine head connecting beam (9) ) is connected with the ball screw moving nut (4), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com