Vertical gallium nitride-based light emitting diode and method of manufacturing the same

A light-emitting diode, gallium nitride-based technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as reducing the reliability of LEDs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

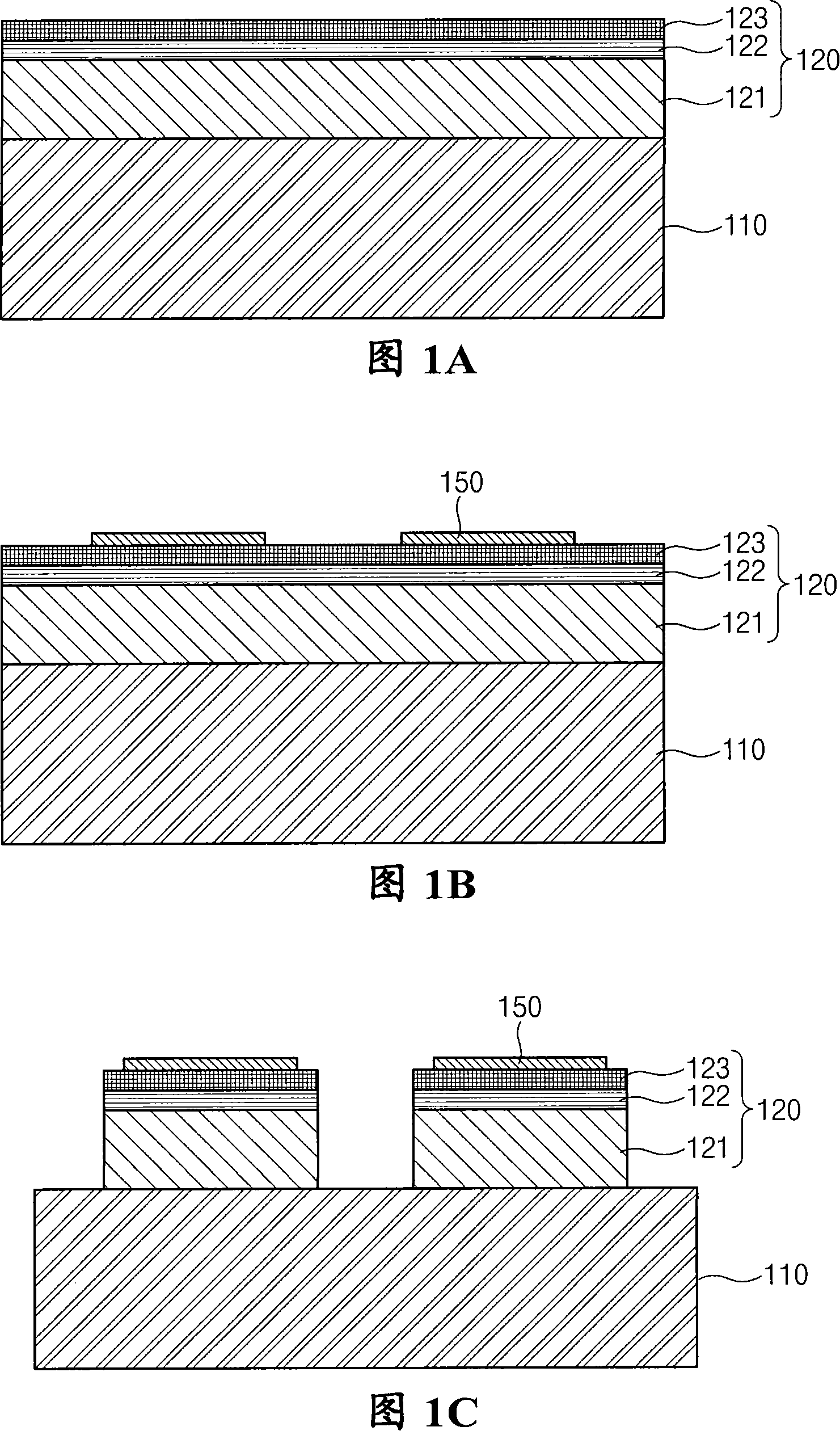

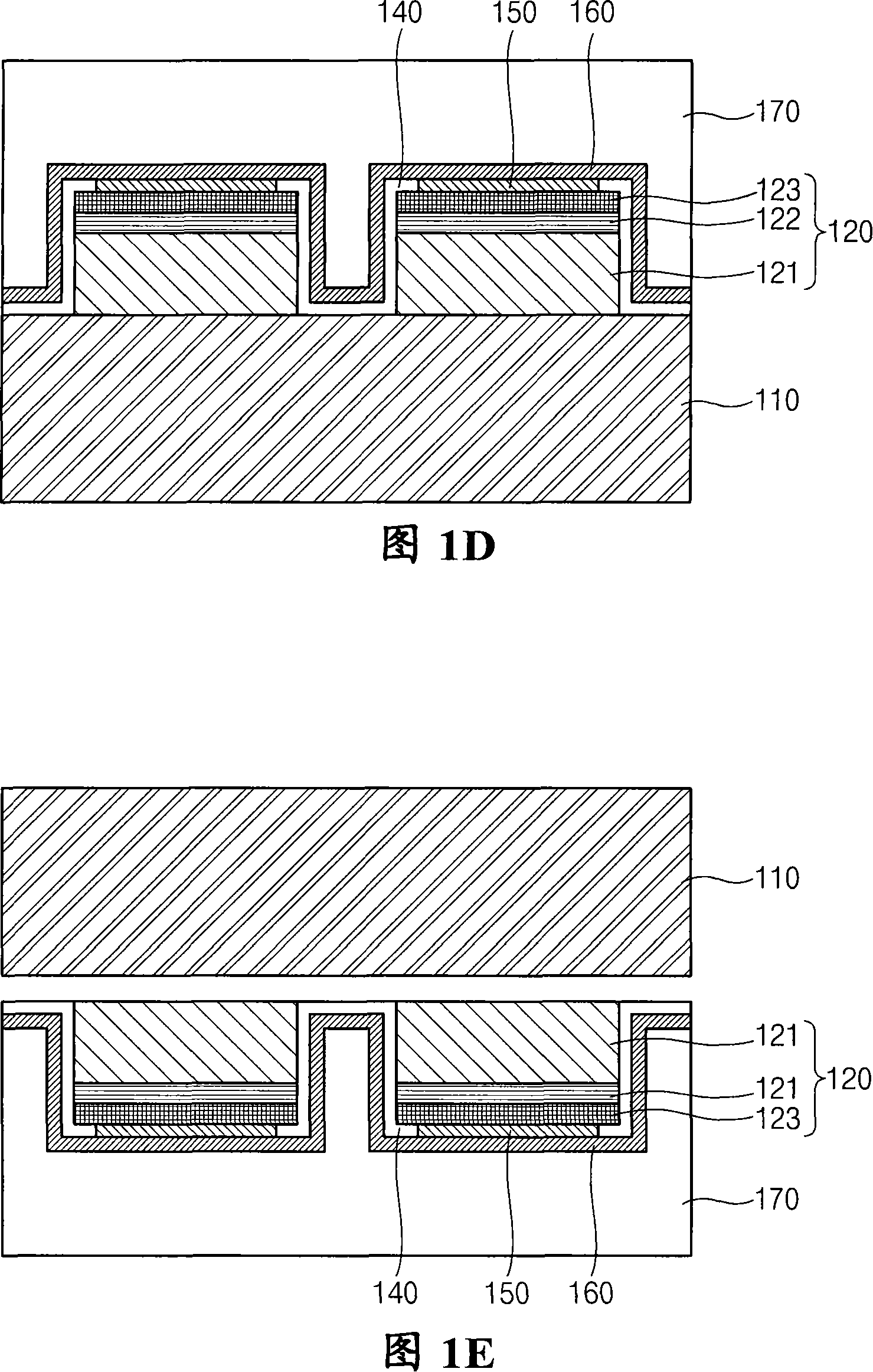

[0058] Referring to FIGS. 3 and 4A to 4M , a vertical GaN-based LED and a method of manufacturing the same according to a first embodiment will be described in detail.

[0059] 3 is a cross-sectional view showing a vertical GaN-based LED structure according to a first embodiment of the present invention. 4A to 4M are cross-sectional views sequentially showing a vertical GaN-based LED manufacturing method according to a first embodiment of the present invention.

[0060] As shown in FIG. 4A, a light emitting structure 320 is formed on a substrate 310, and the light emitting structure 320 is composed of a GaN-based semiconductor layer. In the light emitting structure 320, an n-type GaN-based semiconductor layer 321, an active layer (active layer) 322 composed of a GaN / InGaN layer having a multi-quantum well structure, and a p-type GaN-based semiconductor layer 323 are sequentially stacked. .

[0061] Preferably, the substrate 310 is formed of a transparent material including s...

no. 2 Embodiment approach

[0090]

[0091] A vertical GaN-based LED according to a second embodiment of the present invention will be described in detail with reference to FIGS. 5 to 8 .

[0092] 5 is a cross-sectional view showing a vertical GaN-based LED according to a second embodiment of the present invention. 6 to 8 are plan views illustrating shapes of reflective electrodes according to the present invention.

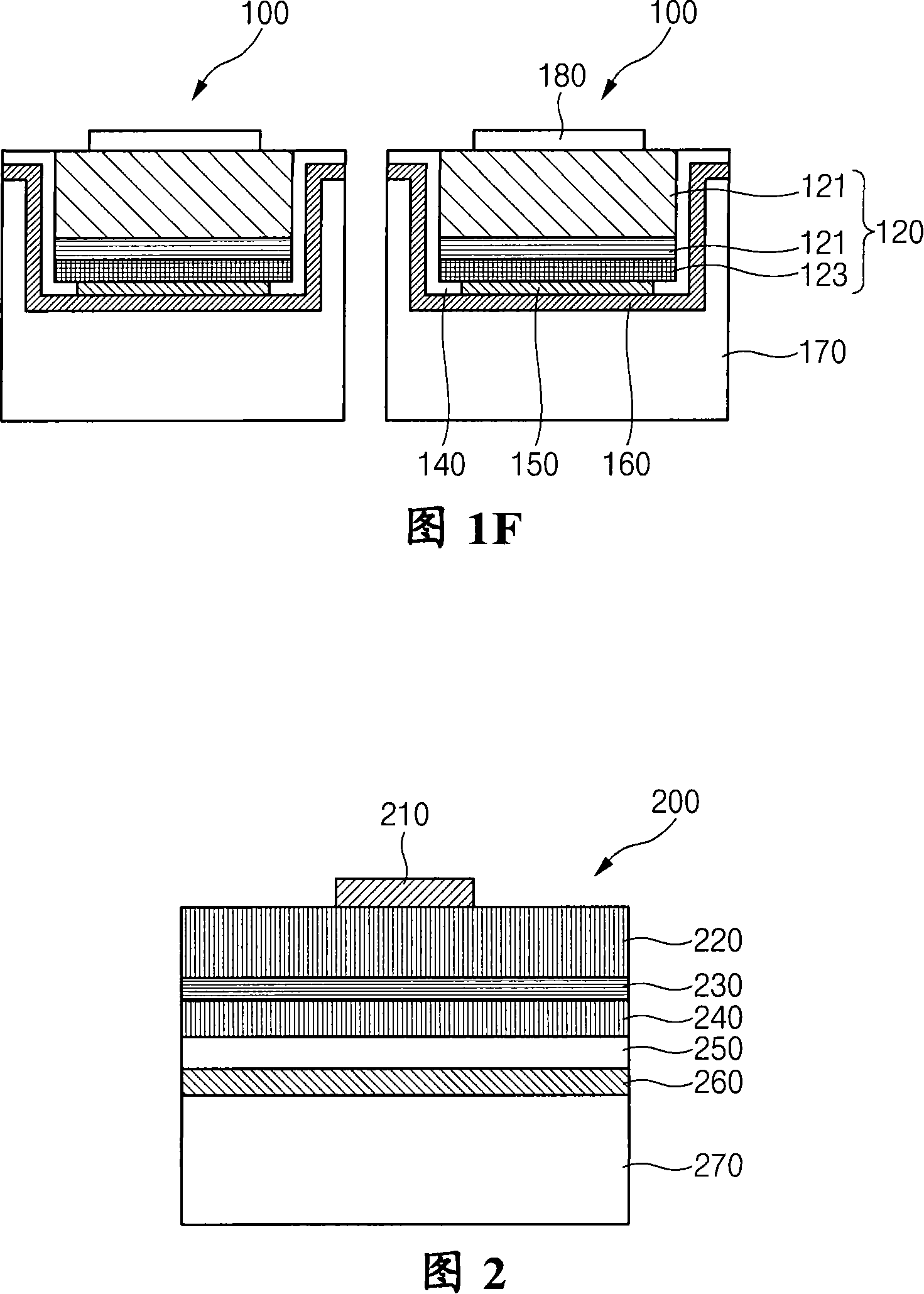

[0093] As shown in FIG. 5, the vertical GaN-based LED 400 according to the second embodiment has an n-electrode 410 at its uppermost portion.

[0094] Under the n-electrode 410, an n-type GaN-based semiconductor layer 420 is formed. More specifically, the n-type GaN-based semiconductor layer 420 may be formed of a GaN layer or a GaN / AlGaN layer doped with n-type impurities.

[0095] In order to enhance the current spreading effect, a transparent electrode (not shown) is further formed between the n-electrode 410 and the n-type GaN-based semiconductor layer 420 .

[0096] Under the n-ty...

no. 3 Embodiment approach

[0117]

[0118] Next, a third specific embodiment of the present invention will be described with reference to FIGS. 10 to 12 . Wherein, the description of the same parts as those of the second specific embodiment is omitted.

[0119] 10 to 12 are cross-sectional views illustrating the structure of a vertical GaN-based LED according to a third embodiment of the present invention.

[0120]As shown in FIGS. 10 to 12 , the vertical GaN-based LED according to the third embodiment has substantially the same configuration as the vertical GaN-based LED according to the second embodiment. However, the vertical GaN-based LED according to the third embodiment is different from the vertical GaN-based LED according to the second embodiment in that the blocking layer 455 is formed of an insulating film so that a part of the reflective electrode is formed to be exposed. outside. The insulating film can be made of oxide-based or nitride-based materials such as SiO 2 、Al 2 o 3 、TiO 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com