Method for producing a target

A manufacturing method and gas technology, applied in the field of sputtering targets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

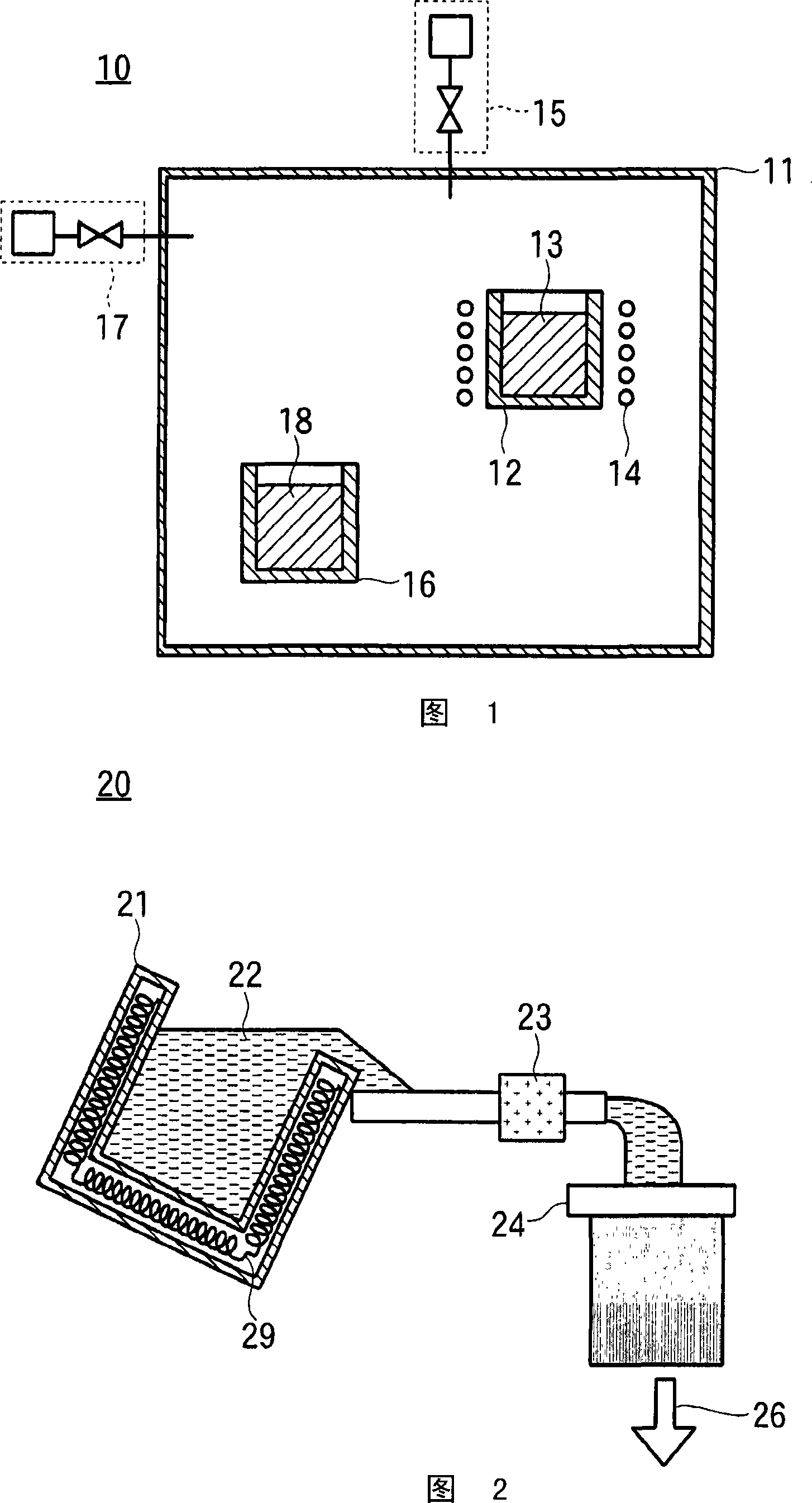

[0041] The manufacturing method of the sputtering target of this invention is demonstrated.

[0042] Reference numeral 10 in FIG. 1 is a primary melting device, which has a vacuum tank 11 . A primary melting crucible 12 is disposed inside the vacuum chamber 11 . In addition, an inert gas introduction system 15 and a vacuum exhaust system 17 are connected to the vacuum tank 11 .

[0043] First, the main material (here, aluminum: Al) and additives (here, cerium: Ce) are charged into the inside of the primary melting crucible 12 in a predetermined ratio, and the inside of the vacuum chamber 11 is vacuumed by the vacuum exhaust system 17. Exhaust until the pressure is below 1Pa.

[0044] Then, an inert gas (herein referred to as argon) is introduced into the inside of the vacuum tank 11 from the inert gas introduction system 15, and the inside of the vacuum tank 11 is boosted to 2600 Pa, which is lower than the atmospheric pressure, forming a primary ambient gas with low oxygen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com