Peduncle filum drying column humidity control method

A control method and drying tower technology, applied in the direction of tobacco preparation, application, tobacco, etc., can solve the problems of outlet material moisture oscillation, oxygen content instability, and material blocking of cut stem drying tower equipment, so as to achieve moisture fluctuation reduction, The effect of reducing fire hazards and stabilizing material flow

- Summary

- Abstract

- Description

- Claims

- Application Information

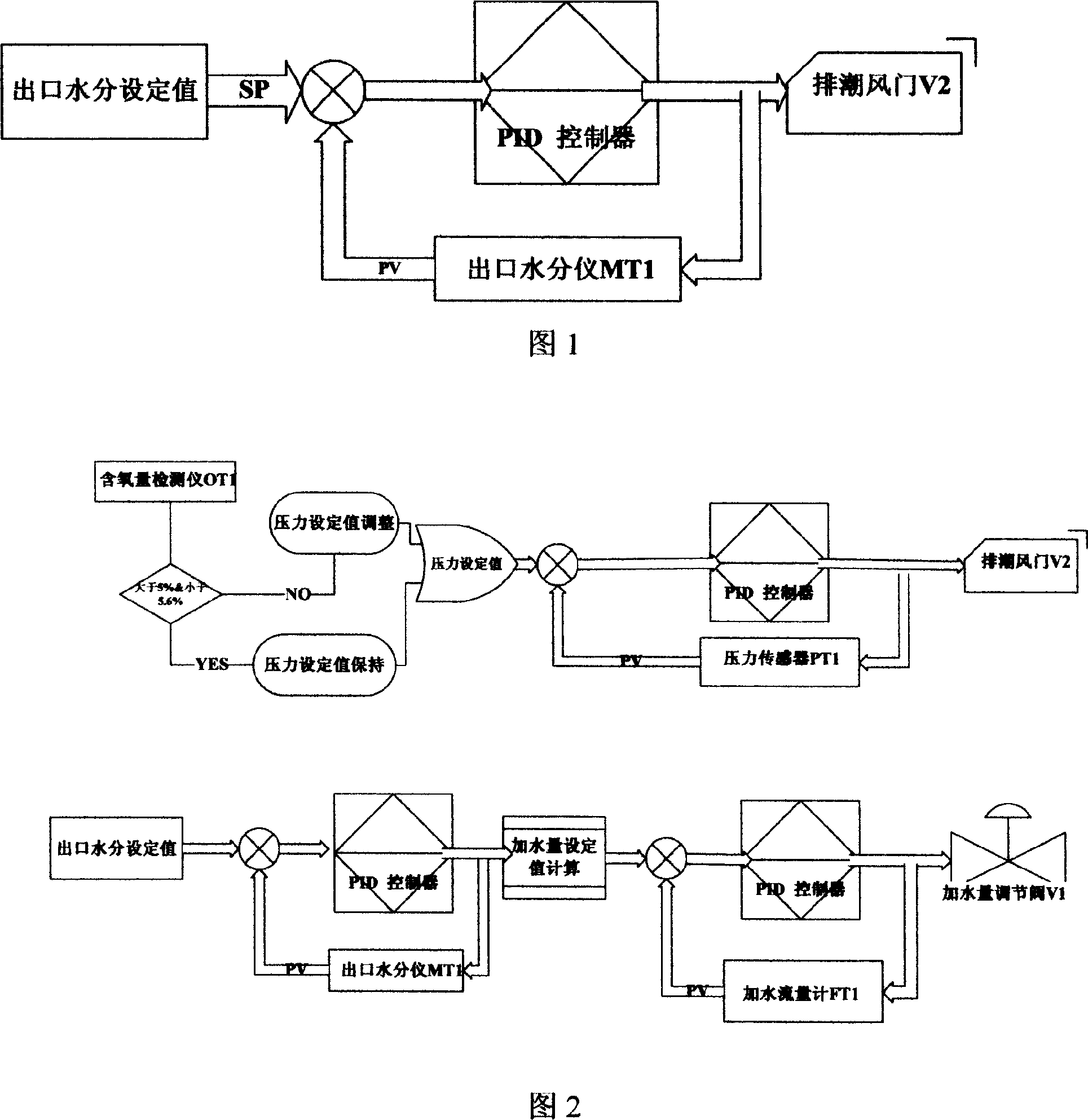

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

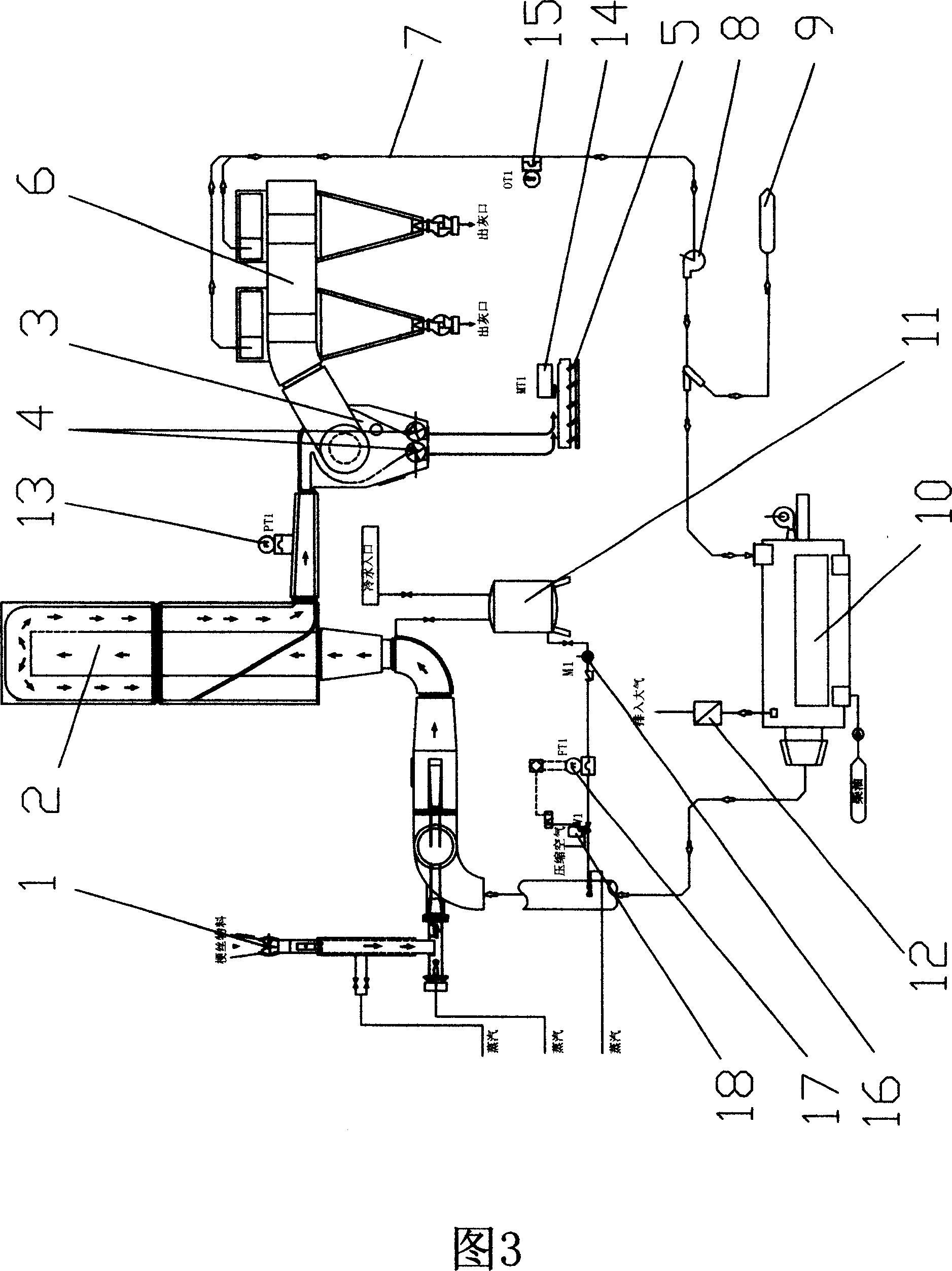

[0024] The cut stem drying tower used in this embodiment is a cut stem drying tower designed by the Italian company COMAS, referred to as SDT.

[0025] See Figure 3 for the equipment and process flow chart used for rapid drying and shaping of the rehydrated high-temperature and high-humidity shredded stems in the tobacco shredded process.

[0026] Its main equipment includes: feed air lock 1, drying tower 2, screen 3, discharge air lock 4, material discharge vibration tank 5, double cyclone dust collector 6, air duct 7, main fan 8, water washing tower 9 , Combustion furnace 10, water tank 11, tidal damper V212.

[0027] The process cycle is as follows: the shredded stem material passes through the feed air lock 1, passes through the drying tower 2, passes through the screen 3 after being dried, and enters the material discharge vibration tank 5 through the discharge air lock 4 to complete the drying and shaping process of the material.

[0028] A pressure sensor RT1 13 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com