Processing method of the hot rolling arrived material convexity in the computing of cold rolled sheet shape initialization

A processing method and technology of cold-rolled plates, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of high price, high cost, complicated maintenance, etc., achieve good plate shape, reduce costs, and save investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0081] In a three-electric transformation project of a tandem cold rolling mill, the incoming convexity of the roll bending force model has been processed according to the present invention, and the automatic setting of the roll bending force can be realized, and the strip shape is in good condition.

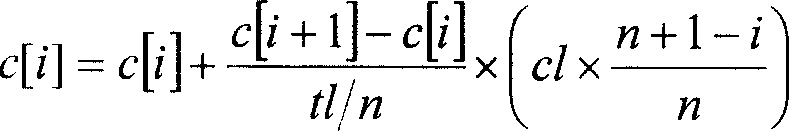

[0082] Examples of convexity processing are as follows:

[0083] Assume that the measured crown values of hot rolling are shown in Table 1;

[0084] Table 1

[0085] 40.00

42.39

44.20

44.98

44.54

42.99

40.70

38.24

36.216

35.11

35.20

36.47

38.60

41.07

43.28

44.69

44.94

43.99

42.06

39.62

37.27

35.60

35.00

35.62

37.31

39.66

42.10

44.01

44.95

44.67

[0086] Assume that the total length of the steel coil is 500m, and the cutting head is 10m. Tension and leveling extension 3%, strip wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com