Vibrating material delivering flow following gestating device

A flow-following inoculation device and vibration feeding technology, which is applied in the mechanical field, can solve the problems of large flow fluctuation range, unstable working performance, low flow accuracy and total feeding accuracy, so as to improve the accuracy of total feeding , Stable and reliable working performance, and the effect of improving the accuracy of equal flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] An example is used to illustrate its specific implementation.

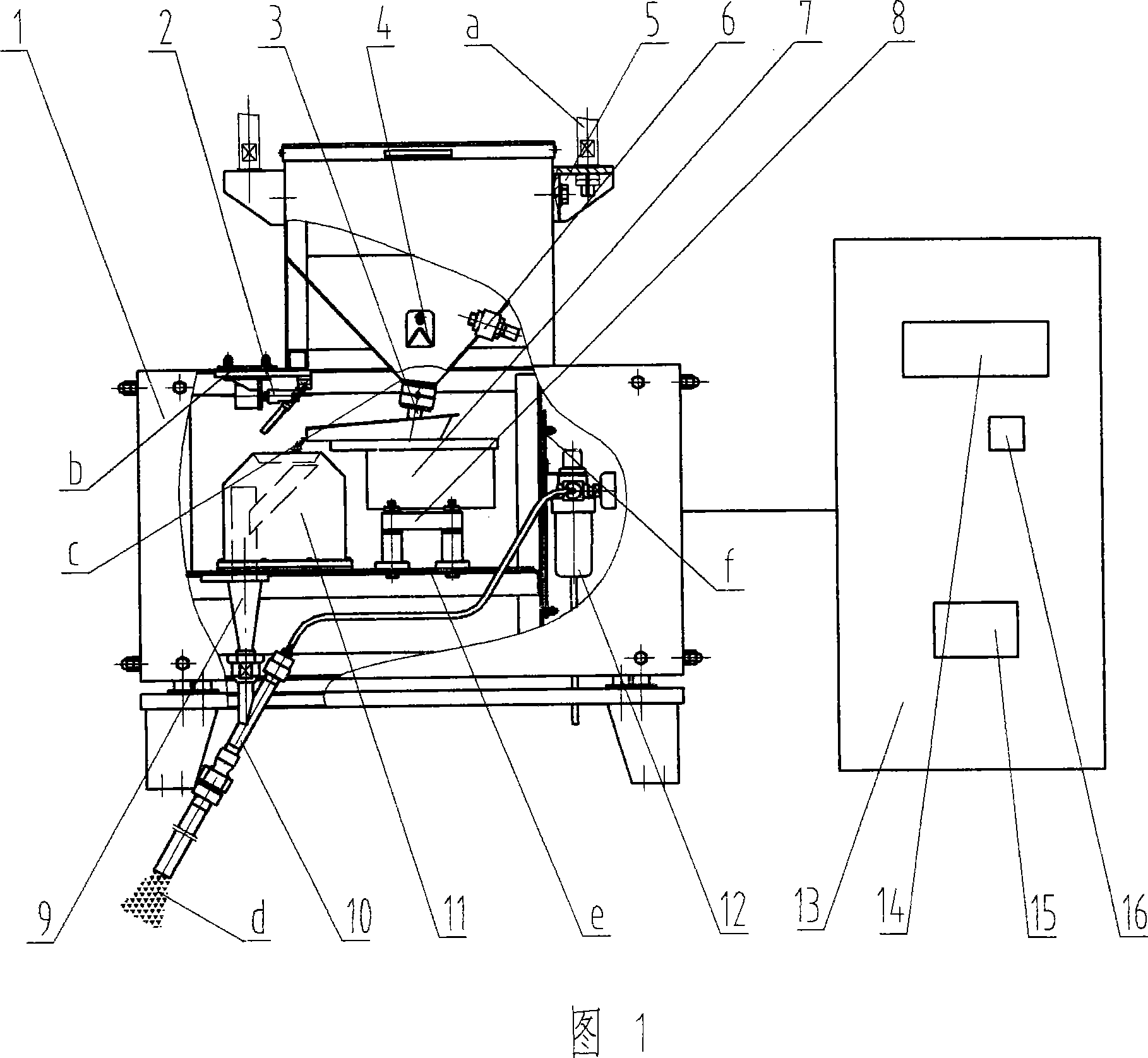

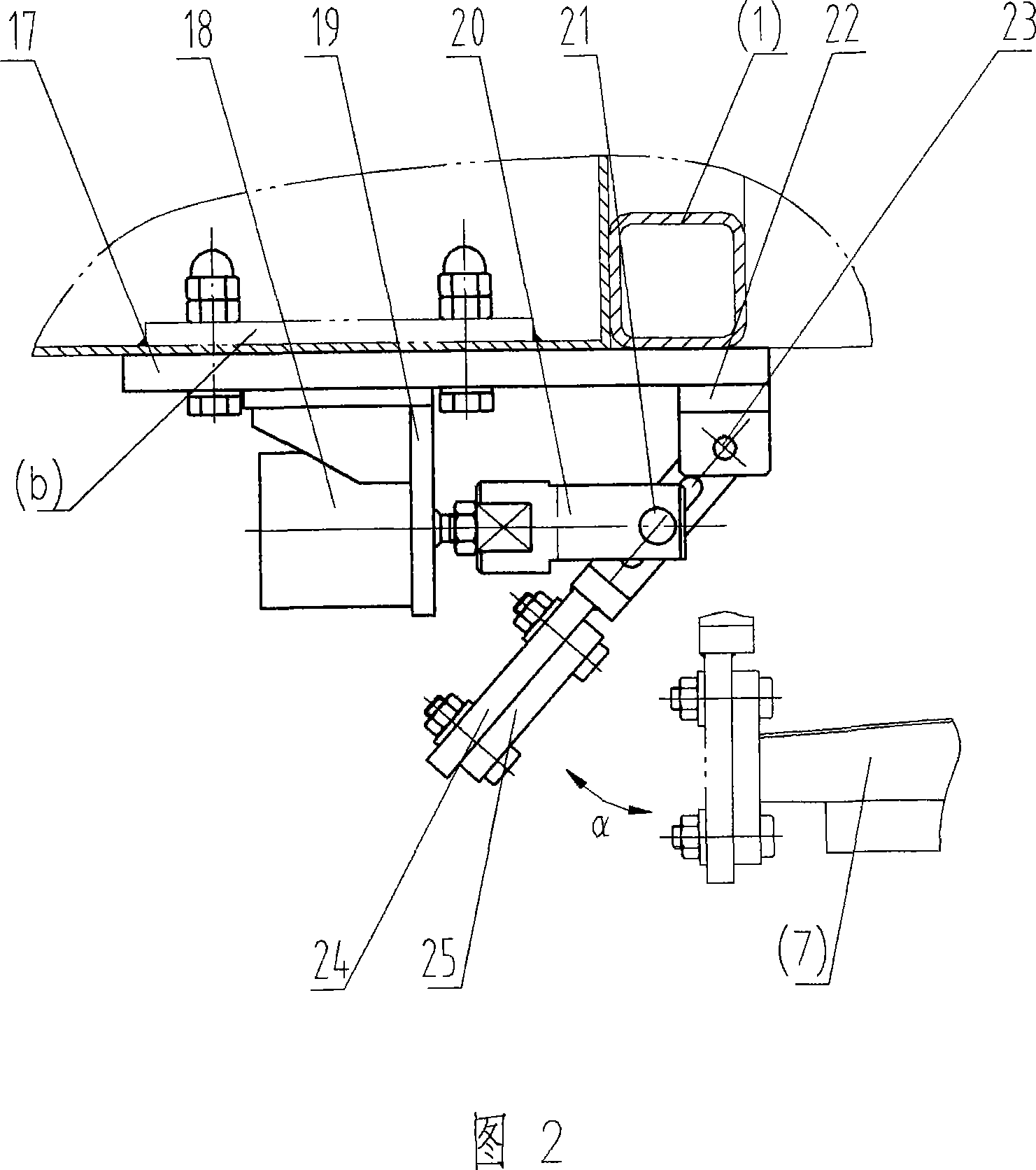

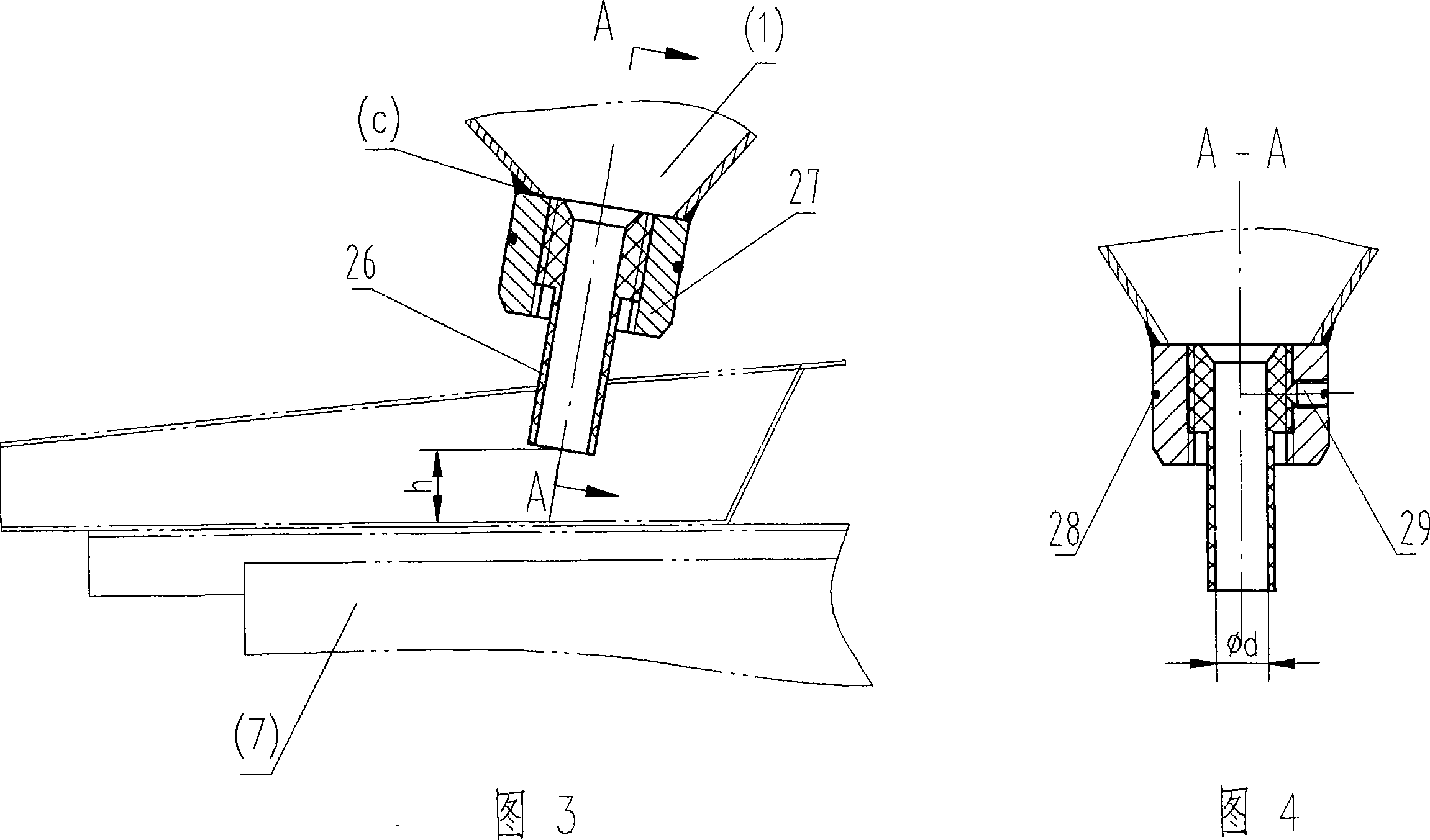

[0024] As can be seen from Fig. 1, a vibrating feed material flow inoculation device includes a host cabinet body 1, a pneumatic sealing assembly 2, a feeding port assembly 3, a hopper pressure limiting plate assembly 4, two lifting lugs 5, a material level sensor 6, Electromagnetic vibrating feeder 7, shock-absorbing base assembly 8, V-shaped funnel hopper 9, three-way feeding pipe assembly 10, micro flow meter 11, low-pressure air circuit assembly 12, and control cabinet 13. In the figure, a is the four booms placed under the additionally configured running mechanism, which are used to hoist and run the flow-following inoculation device to meet the pouring needs of the manual pouring line; b is the upper connecting plate in the main cabinet 1, which is connected to the pneumatic sealing component 2; c is the feeding port of the hopper in the host cabinet, connected to the feeding port assembly 3; d is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com