Windshield wiper connecting plate

A connecting plate and wiper technology, which is applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve the problems of high processing costs, achieve the effects of reducing processing costs, easy assembly, and reducing processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

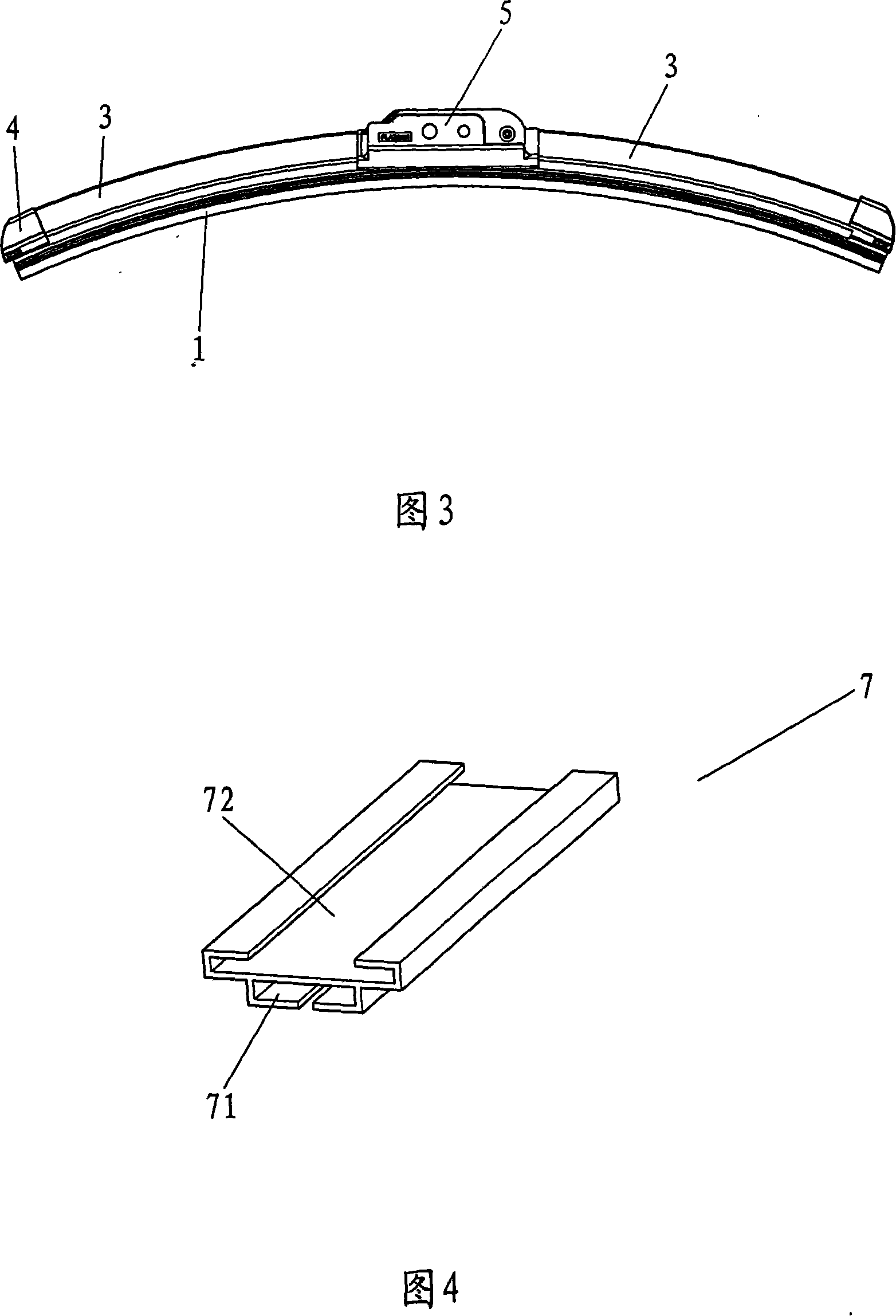

[0015] As shown in FIG. 3 , the wiper according to the present invention mainly includes a long rubber strip 1 and an elastic supporting part 2 , and the rubber strip 1 and the elastic supporting part 2 are connected through a connecting plate 7 . in:

[0016] The structure of the rubber strip 1 is the same as that of the prior art, and its two sides are respectively provided with fixing grooves 11 longitudinally penetrating the rubber strip 1 .

[0017] Only one elastic support member 2 is provided, which is a long plate-shaped body with certain elasticity and strength.

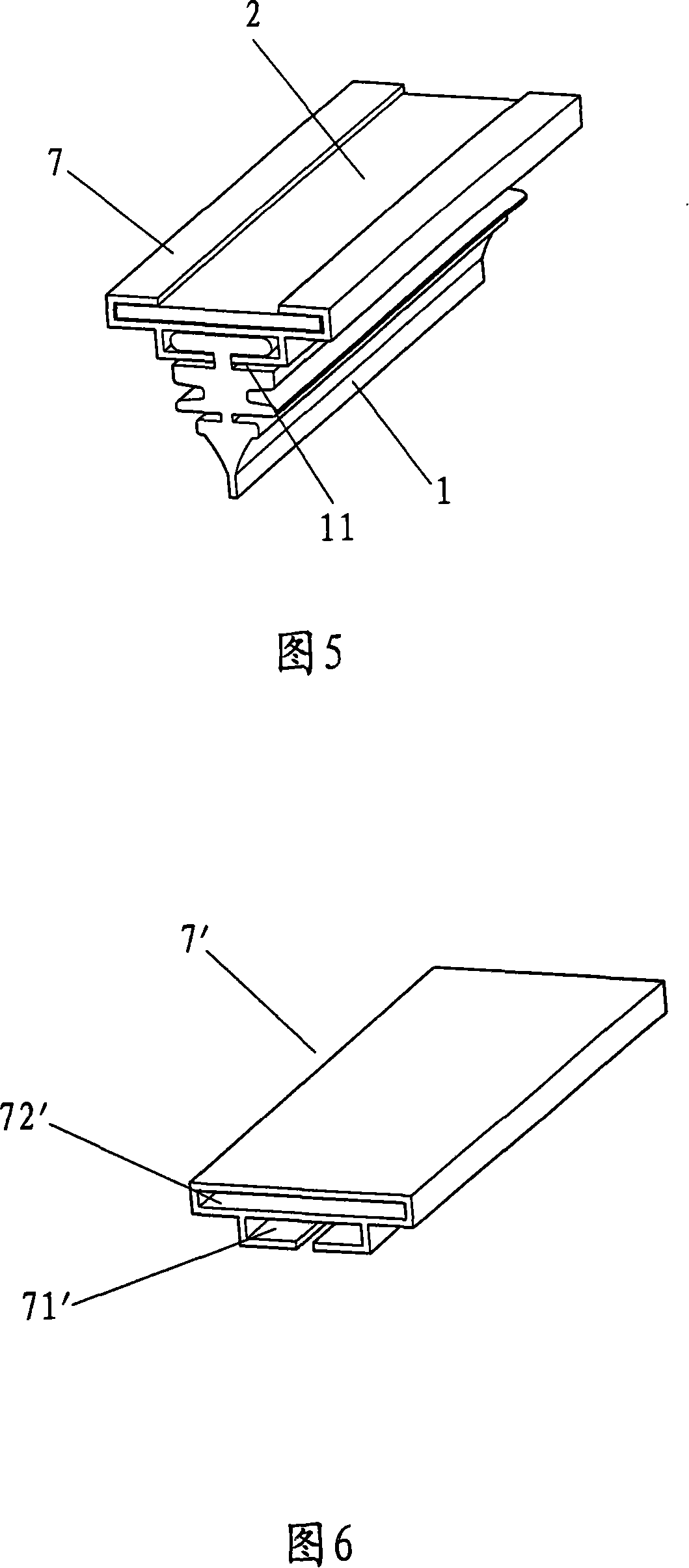

[0018] The connecting plate 7 (shown in FIG. 4 at the same time) can be stretched by plastic to form a material-like structure, and its length is equivalent to that of the above-mentioned rubber strip 1 and elastic support member 2. From the cross-section of the connecting plate 7, its bottom A C-shaped slot 71 with an opening facing downwards is provided, and a connecting slot 72 is provided at the top the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com