Bandage type wine bottle burglar preventor and special unlocking device

An anti-theft device and unlocker technology, which is applied to building locks, lock applications, and non-mechanical transmission-operated locks, can solve the problems of troublesome injection molding, high cost, and high processing cost of lock cylinders, and achieves a release method that saves labor and produces The effect of low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

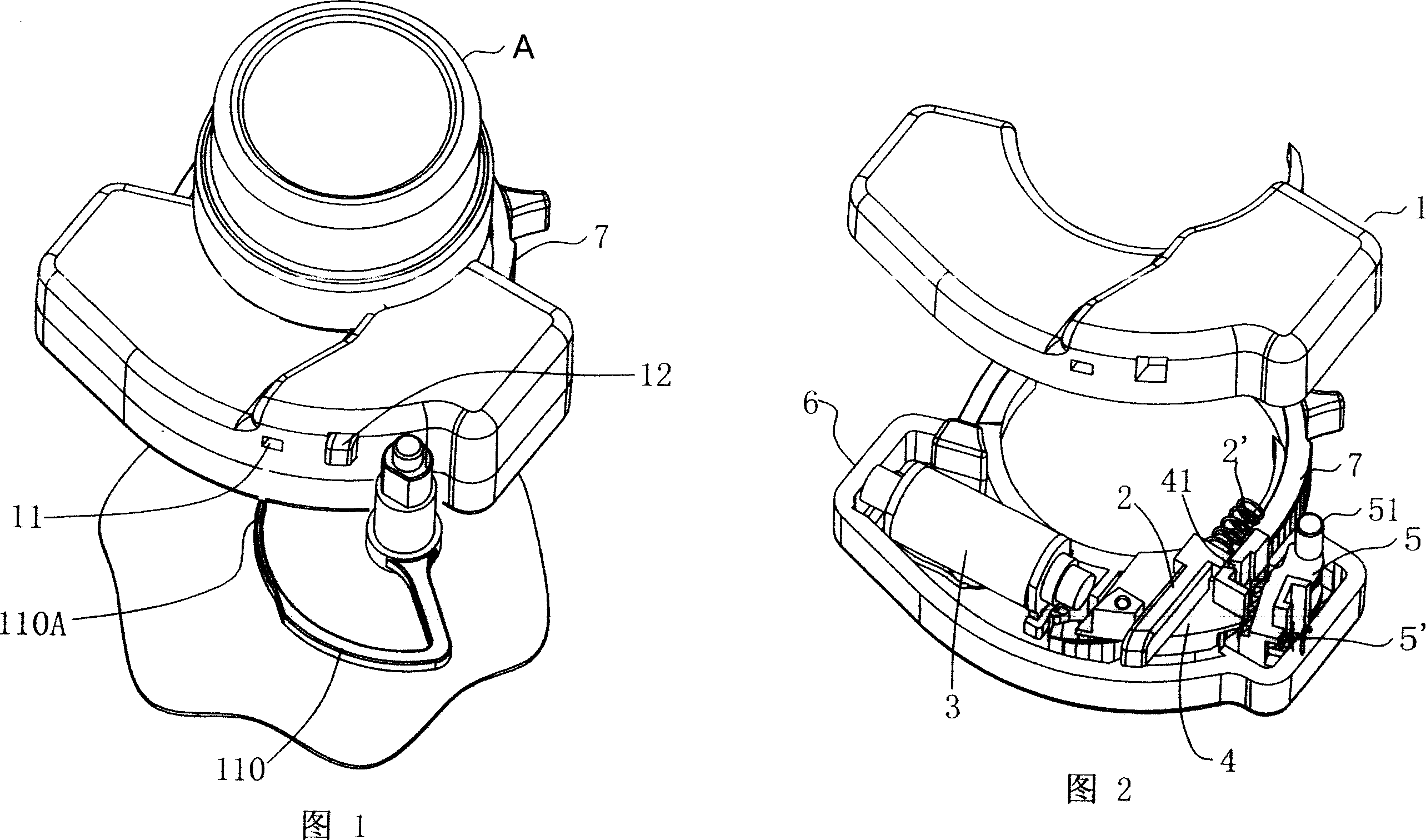

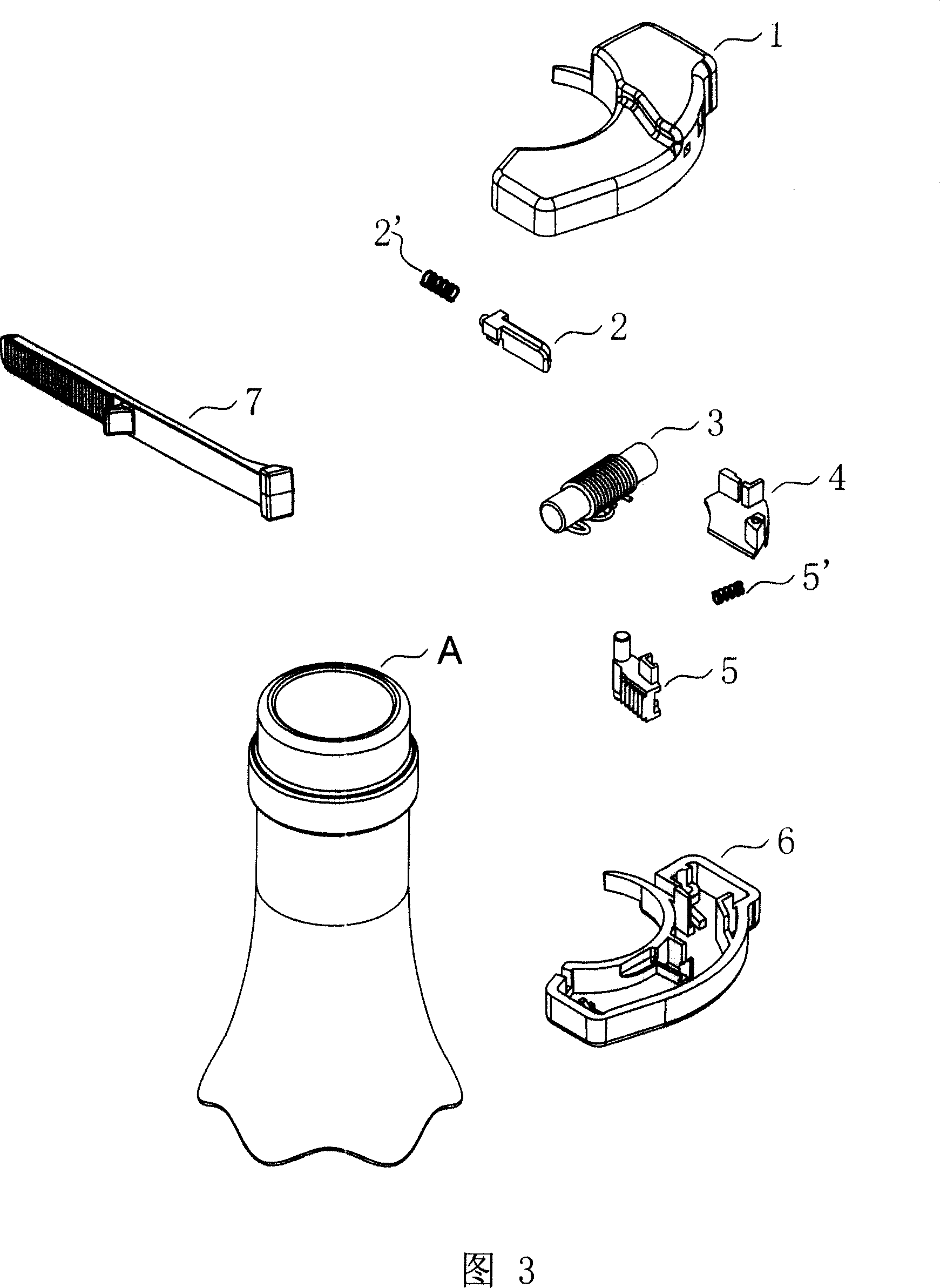

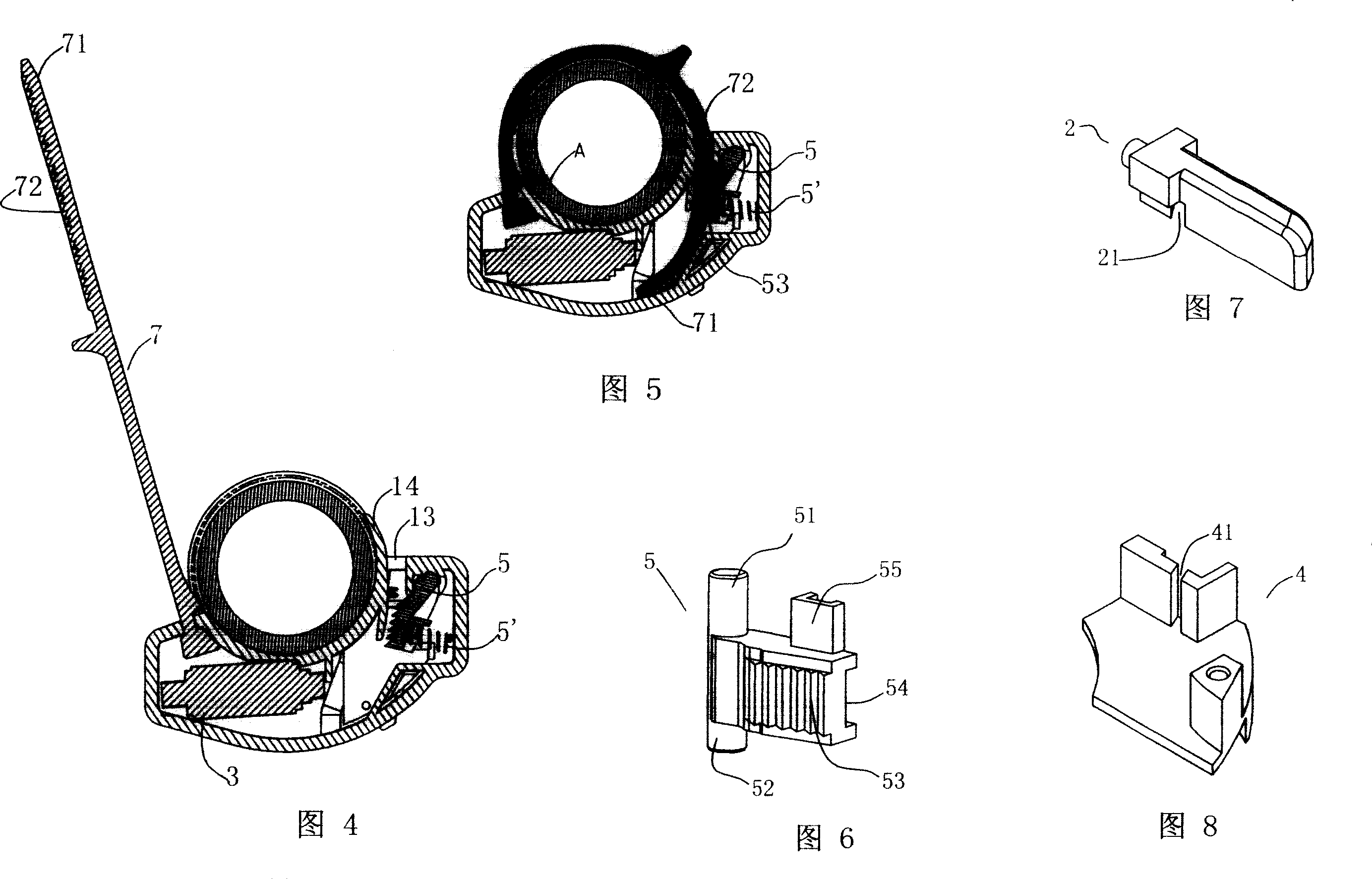

[0024] Further description below in conjunction with accompanying drawings.

[0025] As shown in Figures 1-8, the strap-type wine bottle anti-theft device includes a casing consisting of an upper casing 1 and a lower casing 6, a strap 7, and an EAS anti-theft label 3 installed in the casing (i.e. electromagnetic coil), one end of the strap 7 is connected to the casing, the upper casing 1 and the lower casing 6 are welded together by ultrasonic waves, and the casing is provided with a strap inlet and outlet 13 for the strap free end 71 to enter and exit. A strap anti-reverse device is arranged near the strap inlet and outlet 13, and the strap anti-reverse device includes a self-locking pendulum 5, and an upper pivot 51 and a lower pivot 52 are respectively arranged on the upper and lower sides of one end of the self-locking pendulum 5 , the upper side of the other end of the self-locking pendulum block 5 is provided with a projection 55, which is used for the shift fork of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com